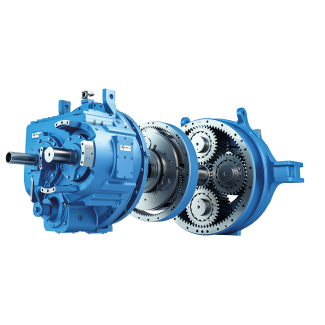

B3KH-7-C on the shafts see Chapter Cooling options se Bevel-helical speed reducer B3

In stock

SKU

B3KH-7-C

$15,000.00

Flender/Flender Gear Units/Bevel-helical speed reducer B3

rocess on Marine Gear Boxes Starting from 2, Wartsila designed gear boxes are manufactured and assembled at Flender GmbH in Germany. This allows us to combine the Wartsila knowledge of the market requirements and design capability with the strong Flender

Germany. This allows us to combine the Wartsila knowledge of the market requirements and design capability with the strong Flender  manufacturing background on gear boxes . Flender produces since 1, beside different types of industrial gearboxes, marine gearboxes for variety

manufacturing background on gear boxes . Flender produces since 1, beside different types of industrial gearboxes, marine gearboxes for variety  of applications and for customers worldwide. The manufacturing of complete marine gearboxes under the Flender brand hereby includes the design,

of applications and for customers worldwide. The manufacturing of complete marine gearboxes under the Flender brand hereby includes the design,  the parts manufacturing and the assembly and testing. The whole process includes also the survey activities with the respective classification societies and procurement activities as well. For the logistics and manufacturing planning the mix between industrial and marine products means special challenge as series production needs different production set up compared to single parts production. special data matrix code stamped on each single part ensures traceability along the entire pr oduction line. The accompanying documentation allows supervising of each step of the machining process within the internal quality system. 4.1. The ma chining process for geared parts Production of the geared parts includes the soft machining, the hardening, th hard machining and the testing. Depending on the single part, either cut bar material or forged material is used. The product portfolio covers spur gear, helical gear pinions, bevel gears, shafts, hollow shafts, casted and welded housings and planet carr iers. Core technologies for geared parts are hobbing and form cutter milling for the soft machining and mainly grinding for the hard machining . 4.2. The Assembly and testing (FAT) The assembly follows the process written down in the internal work instructions. special, adapted, work instruction plan has been generated for the Wrtsil designed gearboxes. Within these instructi ons, each assembly step is

the parts manufacturing and the assembly and testing. The whole process includes also the survey activities with the respective classification societies and procurement activities as well. For the logistics and manufacturing planning the mix between industrial and marine products means special challenge as series production needs different production set up compared to single parts production. special data matrix code stamped on each single part ensures traceability along the entire pr oduction line. The accompanying documentation allows supervising of each step of the machining process within the internal quality system. 4.1. The ma chining process for geared parts Production of the geared parts includes the soft machining, the hardening, th hard machining and the testing. Depending on the single part, either cut bar material or forged material is used. The product portfolio covers spur gear, helical gear pinions, bevel gears, shafts, hollow shafts, casted and welded housings and planet carr iers. Core technologies for geared parts are hobbing and form cutter milling for the soft machining and mainly grinding for the hard machining . 4.2. The Assembly and testing (FAT) The assembly follows the process written down in the internal work instructions. special, adapted, work instruction plan has been generated for the Wrtsil designed gearboxes. Within these instructi ons, each assembly step is| Model Type | Bevel-helical speed reducer B3 |

|---|---|

| Gear Type | Bevel Helical Gear |

| Weight (kg) | 700.000000 |

| Ratio Range | 1 : 12.5…71 |

| Low Speed Output | Hollow shaft with spline acc. to DIN 5480 |

| Nominal Torque | 21700 Nm |

| Mounting Arrangements | Horizontal mounting position |

| Manufacturer | WALTHER FLENDER GMBH |

| Country of Manufacture | Venezuela |

| Data Sheet & Drawings | B3KH-7-C on the shafts see Chapter Cooling options se Bevel-helical speed reducer B3 |