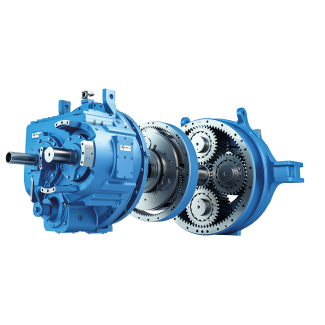

B3-KH-7-D e page onwards Approximate values exact data ac Bevel-helical speed reduction gearbox B3

In stock

SKU

B3-KH-7-D

$15,000.00

Flender/Flender Gear Units/Bevel-helical speed reduction gearbox B3

rocess to exclude human error. An environmentally friendly alternative was devised with this recirculation process, ;.. liquids and chemicalsare saved. In reference to the use of energy,advantages result from the fact that the liquors,once heated and hot,are not drained while

In reference to the use of energy,advantages result from the fact that the liquors,once heated and hot,are not drained while  still hot; instead, the heat can be used to warm up the subsequent batches. Additional advantages result from the closed

still hot; instead, the heat can be used to warm up the subsequent batches. Additional advantages result from the closed  system, with which pollution of the surrounding air, .. with HzS, can be considerably reduced. Automatic batch processing machine As

system, with which pollution of the surrounding air, .. with HzS, can be considerably reduced. Automatic batch processing machine As  mentionedabove,the machineconsistsof totalof 1chambers.Accesstotheendofeach processing step is important, so that the skins to be processed can be examined in reference to their quality. For this purpose, the skins are removed from slanted chutes at the end of the indt- vidual blocks. The blocks are spaced 1 cm apart. Inaddition,thelastchamberofblocks 1 and2 hasanunloadingdoorwhichcanalsobeopened for sampling. Thechambersofa blockareinterconnected bypipes,sothattheIiquidcanflowfromthefirstto the last,chamber. The liquid in the last chamber of block is pumped off and fed into the previouschamber.The last chamber of each block is closed by sliding doors which prevent the liquid from escaping. The lint enerated in the pickling and chrome tanning block is separated on special filter unit during tEe repumping cycle. All chemicals are pumped into the chambers from storage tanks. There are three such tanks. Each storage tank has capacity of 2 m3 for chrome and salt solutions which are dissolved in tank before use. In addition, we use carbon dioxide for deliming purposes. Aseparatetank had to be purchased to store the carbon dioxide. The dwell time of the skins in each chamber can be varied. At our company, itwas 1 minutes. This proved to be practical in the course of the development. Thus, one hour is required for deliming and drenching, 4 minutes for picklin and another hour for chrome tanning. This dwell time in the i

mentionedabove,the machineconsistsof totalof 1chambers.Accesstotheendofeach processing step is important, so that the skins to be processed can be examined in reference to their quality. For this purpose, the skins are removed from slanted chutes at the end of the indt- vidual blocks. The blocks are spaced 1 cm apart. Inaddition,thelastchamberofblocks 1 and2 hasanunloadingdoorwhichcanalsobeopened for sampling. Thechambersofa blockareinterconnected bypipes,sothattheIiquidcanflowfromthefirstto the last,chamber. The liquid in the last chamber of block is pumped off and fed into the previouschamber.The last chamber of each block is closed by sliding doors which prevent the liquid from escaping. The lint enerated in the pickling and chrome tanning block is separated on special filter unit during tEe repumping cycle. All chemicals are pumped into the chambers from storage tanks. There are three such tanks. Each storage tank has capacity of 2 m3 for chrome and salt solutions which are dissolved in tank before use. In addition, we use carbon dioxide for deliming purposes. Aseparatetank had to be purchased to store the carbon dioxide. The dwell time of the skins in each chamber can be varied. At our company, itwas 1 minutes. This proved to be practical in the course of the development. Thus, one hour is required for deliming and drenching, 4 minutes for picklin and another hour for chrome tanning. This dwell time in the i| Model Type | Bevel-helical speed reduction gearbox B3 |

|---|---|

| Gear Type | Bevel Helical Gear |

| Weight (kg) | 700.000000 |

| Ratio Range | 1 : 12.5…71 |

| Low Speed Output | Hollow shaft with spline acc. to DIN 5480 |

| Nominal Torque | 21700 Nm |

| Mounting Arrangements | Horizontal mounting position |

| Manufacturer | A. Friedr. Flender AG & Co. KG |

| Country of Manufacture | Vietnam |

| Data Sheet & Drawings | B3-KH-7-D e page onwards Approximate values exact data ac Bevel-helical speed reduction gearbox B3 |