e space for pump pipes and cover please contact B3HH-5-C Bevel-helical speed reducer B3

In stock

SKU

B3HH-5-C

$12,000.00

Flender/Flender Gear Units/Bevel-helical speed reducer B3

ponents provided in the complete gear unit documentation. 5.5.1 Connecting the motor pump 5.5 Connecting components Procedure To connect the motor pump, proceed as follows: 1.Make sure that the connections of the motor pump are not damaged. 2.Connect up the

motor pump, proceed as follows: 1.Make sure that the connections of the motor pump are not damaged. 2.Connect up the  motor pump according to the terminal diagram and the relevant operat- ing instructions. Further information You can find additional information

motor pump according to the terminal diagram and the relevant operat- ing instructions. Further information You can find additional information  about the motor pump in the terminal diagrams and the lists of equipment provided in the complete gear unit documentation.

about the motor pump in the terminal diagrams and the lists of equipment provided in the complete gear unit documentation.  5.5.1 Electrical connections 5.5 Connecting components Procedure DANGER Electric shock Live parts can cause electric shock. Ensure that the entire plant is de-energised before starting electrical installation work. Carefully observe the five safety rules ( Page . To connect the motors and monitoring devices, proceed as follows: 1.Ensure that the connections of the motors and monitoring devices are not damaged. 2.Connect up the motors and monitoring devices according to the terminal diagram and the relevant operating instructions. Assembly 5.6 Tightening procedure 6 Edition 0/2 B5-0 en3.Insulate all cable entry points (glands) at electrical equipment as required for the envir- onment in which the equipment will operate. Further information You can find additional information about the electrical connections in the terminal diagrams and equipment lists provided in the complete gear unit documentation. 5.6 Tightening procedure 5.6 Tightening procedure 5.6.1 Introduction 5.6 Tightening procedure Bolts The bolts must have the following properties: Made of steel Black-annealed or phosphatised Lightly oiled (do not add additional oil) Information Replacing bolts Replace any bolts that are no longer fit for use by bolts of the same type and strength class. Mating threads The mating threads must have the following properties: Made of steel or cast iron Dry, cut threads Information Using lubricant As rule, lubricants may not be used, because this can resul

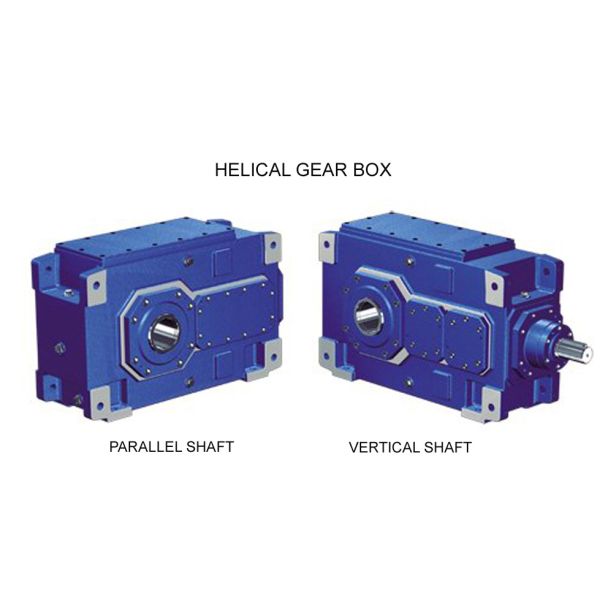

5.5.1 Electrical connections 5.5 Connecting components Procedure DANGER Electric shock Live parts can cause electric shock. Ensure that the entire plant is de-energised before starting electrical installation work. Carefully observe the five safety rules ( Page . To connect the motors and monitoring devices, proceed as follows: 1.Ensure that the connections of the motors and monitoring devices are not damaged. 2.Connect up the motors and monitoring devices according to the terminal diagram and the relevant operating instructions. Assembly 5.6 Tightening procedure 6 Edition 0/2 B5-0 en3.Insulate all cable entry points (glands) at electrical equipment as required for the envir- onment in which the equipment will operate. Further information You can find additional information about the electrical connections in the terminal diagrams and equipment lists provided in the complete gear unit documentation. 5.6 Tightening procedure 5.6 Tightening procedure 5.6.1 Introduction 5.6 Tightening procedure Bolts The bolts must have the following properties: Made of steel Black-annealed or phosphatised Lightly oiled (do not add additional oil) Information Replacing bolts Replace any bolts that are no longer fit for use by bolts of the same type and strength class. Mating threads The mating threads must have the following properties: Made of steel or cast iron Dry, cut threads Information Using lubricant As rule, lubricants may not be used, because this can resul| Model Type | Bevel-helical speed reducer B3 |

|---|---|

| Gear Type | Bevel Helical Gear |

| Weight (kg) | 560.000000 |

| Ratio Range | 1 : 12.5…71 |

| Low Speed Output | Hollow shaft with keyway acc. to DIN 6885/1 |

| Nominal Torque | 11600 Nm |

| Mounting Arrangements | Horizontal mounting position |

| Manufacturer | A. Fried. Flender AG |

| Country of Manufacture | Ireland |

| Data Sheet & Drawings | e space for pump pipes and cover please contact B3HH-5-C Bevel-helical speed reducer B3 |