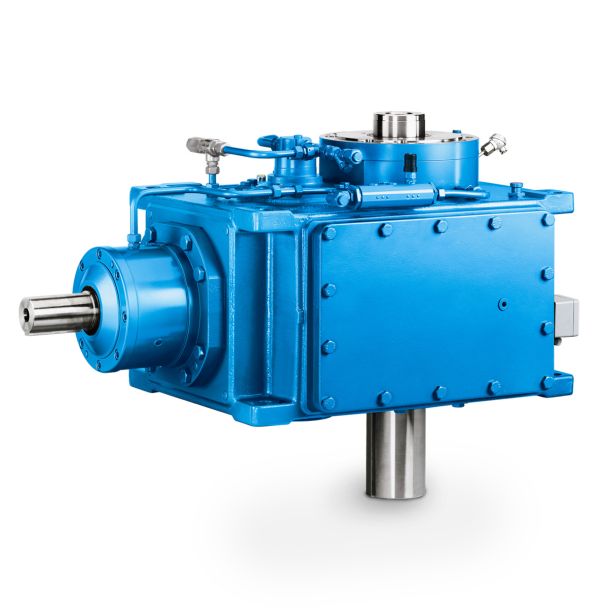

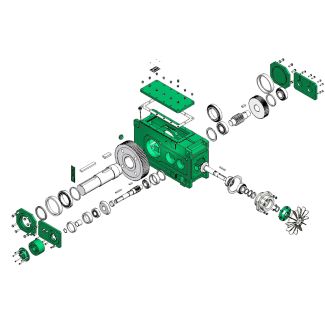

Bevel-helical gear unit B3 p E h h f h he dl G H V Forced lubrication by flan B3CH-14-C

In stock

SKU

B3CH-14-C

$58,928.57

Flender/Flender Gear Units/Bevel-helical gear unit B3

out on the small test bench. Therefore 1 test runs with module 4.5 mm and four with module 3.2 mm are made to investigate the size influence on the one hand, and explore non-investigated parameters on the other. Besides the

are made to investigate the size influence on the one hand, and explore non-investigated parameters on the other. Besides the  module ratio of nearly five, both gear sizes have almost similar geom-etry. This leads to comparable Hertzian contact stress distribution

module ratio of nearly five, both gear sizes have almost similar geom-etry. This leads to comparable Hertzian contact stress distribution  along the path of contact. All other operating conditions have been kept constant to all test runs, as there are

along the path of contact. All other operating conditions have been kept constant to all test runs, as there are  lubricant, lubrication tem -perature = 9C, circumferential speed = 8.3 / and minimal lubricant film thickness. In order to achieve distinguish-able results, the damage load stage against micropitting of the lubricant is chosen low = 8. The test gears of the large test bench have an arithmetical mean rough-ness of the flanks that ranges between Ra = 0.1 up to 0.7 , and long linear tip reliefs beginning at the points of single engagement that are between = 5 and 1 . For the test runs on the small test bench, the aritmetical mean rough-ness of the flanks is adjusted in order to achieve the same minimal lubricant film thickness as on the large test bench; the tip reliefs of the small gears are chosen for the same Hertzian contact stress on the pitch circle as for the large gears. The low costs for small gears enable variants of the pro-file shift and tip relief investigations, in addition to the size-effect test runs. Table 2 shows the investigated param- eters on the large gearbox. Earlier inves-tigations have shown the major influ-ence of the arithmetical mean rough-ness on the appearance of micropitting. New production technologies such as super finishing enable reduction in the Table 1 Test bench parameters Centre distance 4 mm Maximum cycling power Pcyc 6 MW Maximum brace torque T2 1 kNm Power of electrical drive PDrive 2 kW Load appliance back-to-back with controlled hydraulic bracing unit Figure 3 Big gearbox test bench. September/October 2 | GEAR TECHNOLOGY surface roughnes

lubricant, lubrication tem -perature = 9C, circumferential speed = 8.3 / and minimal lubricant film thickness. In order to achieve distinguish-able results, the damage load stage against micropitting of the lubricant is chosen low = 8. The test gears of the large test bench have an arithmetical mean rough-ness of the flanks that ranges between Ra = 0.1 up to 0.7 , and long linear tip reliefs beginning at the points of single engagement that are between = 5 and 1 . For the test runs on the small test bench, the aritmetical mean rough-ness of the flanks is adjusted in order to achieve the same minimal lubricant film thickness as on the large test bench; the tip reliefs of the small gears are chosen for the same Hertzian contact stress on the pitch circle as for the large gears. The low costs for small gears enable variants of the pro-file shift and tip relief investigations, in addition to the size-effect test runs. Table 2 shows the investigated param- eters on the large gearbox. Earlier inves-tigations have shown the major influ-ence of the arithmetical mean rough-ness on the appearance of micropitting. New production technologies such as super finishing enable reduction in the Table 1 Test bench parameters Centre distance 4 mm Maximum cycling power Pcyc 6 MW Maximum brace torque T2 1 kNm Power of electrical drive PDrive 2 kW Load appliance back-to-back with controlled hydraulic bracing unit Figure 3 Big gearbox test bench. September/October 2 | GEAR TECHNOLOGY surface roughnes| Model Type | Bevel-helical gear unit B3 |

|---|---|

| Gear Type | Bevel Helical Gear |

| Weight (kg) | 2750.000000 |

| Ratio Range | 1 : 16…90 |

| Low Speed Output | Solid shaft without parallel key |

| Nominal Torque | 113000 Nm |

| Mounting Arrangements | Horizontal mounting position |

| Manufacturer | A. Friedr. Flender GmbH |

| Country of Manufacture | Honduras |

| Data Sheet & Drawings | Bevel-helical gear unit B3 p E h h f h he dl G H V Forced lubrication by flan B3CH-14-C |