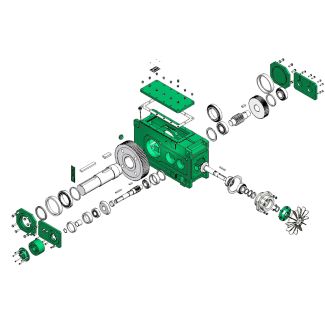

Bevel-helical gear box B3 ump Oil filter Optional pressure relief valve max B3-CH-15-A

In stock

SKU

B3-CH-15-A

$79,928.57

Flender/Flender Gear Units/Bevel-helical gear box B3

outer sides and for the tip of the grinding wheel. To ensure an even grinding wheel surface, the dressing speed should be chosen to make the contact ratio >1. special aspect results from the different contact conditions on the inner

should be chosen to make the contact ratio >1. special aspect results from the different contact conditions on the inner  and outer sides of the grinding wheel when dressing cup wheels. Figure 6.3 illustrates the way in which the contact

and outer sides of the grinding wheel when dressing cup wheels. Figure 6.3 illustrates the way in which the contact  arc, when dressing the inner side, is signicantly longer than that when dressing the outer side. These conditions are similar

arc, when dressing the inner side, is signicantly longer than that when dressing the outer side. These conditions are similar  to internal and external cylindrical grinding. In this case, the equivalent grinding wheel diameter is used to compare the processes [ CZEN0 ]. Fig. 6.2 Contact ratio in dressing [ WESS0 ]6.5 Grinding Spiral Bevel Gears 2 Similarly, it is possible to calculate the equivalent dresser roll diameter eqd, which combined to the tangential dresser infeed eddetermines the contact length lgdbetween the dresser roll and the grinding wheel. The difference in contact length produces different theoretical grinding wheel wavinesses on the two grinding wheel anks (Table 6.. The different ank angles of the grinding wheel have signicant inuence on the achievable surface roughness of the bevel gear. The chip thickness is smaller when the outside of the grinding wheel is dressed at the smaller ank angle. As result, the grinding wheel surface is more nely proled and measurably ner surface is ground than on the inside with the larger ank angle. Fig. 6.3 Contact conditions for dressing cup grinding wheels [ WESS0 ] Table 6.1 Calculating the contact length Designation Formula No. Equivalent dresser roll diameter outer ankdeqddS/C1dR dSdR(6. Equivalent dresser roll diameter inner ankdeqddS/C1dR dSdR(6. Contact length lgd ad/C1tanS/C1deqdp(6.2 6 Manufacturing Process This means that different dressing parameters have to be used in order to generate the same surface roughness on both anks. This can be done by varyingthe contact ratio with guide values ( d1.... 6.6 Lapping 6.6.1 Development History In the

to internal and external cylindrical grinding. In this case, the equivalent grinding wheel diameter is used to compare the processes [ CZEN0 ]. Fig. 6.2 Contact ratio in dressing [ WESS0 ]6.5 Grinding Spiral Bevel Gears 2 Similarly, it is possible to calculate the equivalent dresser roll diameter eqd, which combined to the tangential dresser infeed eddetermines the contact length lgdbetween the dresser roll and the grinding wheel. The difference in contact length produces different theoretical grinding wheel wavinesses on the two grinding wheel anks (Table 6.. The different ank angles of the grinding wheel have signicant inuence on the achievable surface roughness of the bevel gear. The chip thickness is smaller when the outside of the grinding wheel is dressed at the smaller ank angle. As result, the grinding wheel surface is more nely proled and measurably ner surface is ground than on the inside with the larger ank angle. Fig. 6.3 Contact conditions for dressing cup grinding wheels [ WESS0 ] Table 6.1 Calculating the contact length Designation Formula No. Equivalent dresser roll diameter outer ankdeqddS/C1dR dSdR(6. Equivalent dresser roll diameter inner ankdeqddS/C1dR dSdR(6. Contact length lgd ad/C1tanS/C1deqdp(6.2 6 Manufacturing Process This means that different dressing parameters have to be used in order to generate the same surface roughness on both anks. This can be done by varyingthe contact ratio with guide values ( d1.... 6.6 Lapping 6.6.1 Development History In the| Model Type | Bevel-helical gear box B3 |

|---|---|

| Gear Type | Bevel Helical Gear |

| Weight (kg) | 3730.000000 |

| Ratio Range | 1 : 12.5…71 |

| Low Speed Output | Solid shaft without parallel key |

| Nominal Torque | 153000 Nm |

| Mounting Arrangements | Horizontal mounting position |

| Manufacturer | Flender Guss Gmbh & Co. Kg |

| Country of Manufacture | Hungary |

| Data Sheet & Drawings | Bevel-helical gear box B3 ump Oil filter Optional pressure relief valve max B3-CH-15-A |