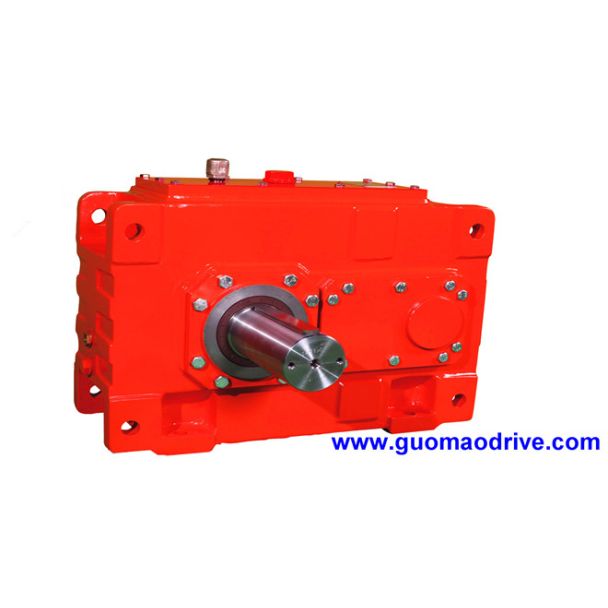

s H H H and H Shaft extension on both sides Gea B3-VH9-B Bevel-helical gear boxes B3

In stock

SKU

B3-VH9-B

$19,285.71

Flender/Flender Gear Units/Bevel-helical gear boxes B3

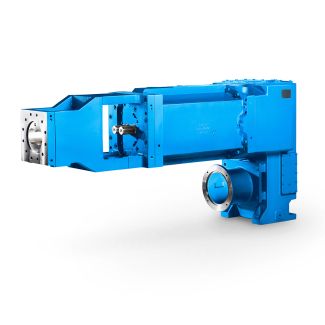

on of rotation. The gear units are characterised by low noise level. This is achieved by helical gears with high contact ratio and special sound-damping housings. The good temperature characteristics of the gear unit are achieved by its high degree

contact ratio and special sound-damping housings. The good temperature characteristics of the gear unit are achieved by its high degree  of ef ficiency, large housing surface and performance-related cooling system. Note: Unless otherwise agreed by contract, the gear units must

of ef ficiency, large housing surface and performance-related cooling system. Note: Unless otherwise agreed by contract, the gear units must  not be exposed to harmful environmental factors such as chemical products, high air pollution and ambienttemperatures outside the range 0

not be exposed to harmful environmental factors such as chemical products, high air pollution and ambienttemperatures outside the range 0  to + 4 . 5.2 Housing The housing is made of cast iron; if necessary, it can also be made of steel. The housing is designed as multi-piece. It is of torsionally rigid design and its shape imparts very favourable noise and temperature characterics. The housing is fitted with adequately dimensioned lifting eyes, inspection or assembly covers.An oil-sight glass for oil level checking, an oil drain plug for oil changes and an air filter for aerating and ventilating the gear unit are provided. Colour codes for ventilating, oil inlet, oil level and oil drainage: Ventilating: yellow Oil inlet: yellow Oil level: red Lubrication points: red Oil drain: white For detailed view of the gear unit, the drawings in the gear-unit documentation must be observed. 5.3 Toothed components The toothed components of the gear unit are case-hardened. Helical-gear teeth are ground. The high quality of the teeth leads to significant noise reduction and ensures safe and reliable running. The gears are connected with the shafts by interference fits and parallel keys or by shrink fits. These types of joints transmit with adequate reliability the torques generated.Caution! BA 5 EN 1.0.4 Lubrication 5.4.1 Dip lubrication Unless otherwise stated in the order documentation, the teeth and bearings are adequately splash-lubricated with oil by the gearwheels. This means that the gear units require very littlemaintenance. 5.4.2 Pressure lubrication by external or ad

to + 4 . 5.2 Housing The housing is made of cast iron; if necessary, it can also be made of steel. The housing is designed as multi-piece. It is of torsionally rigid design and its shape imparts very favourable noise and temperature characterics. The housing is fitted with adequately dimensioned lifting eyes, inspection or assembly covers.An oil-sight glass for oil level checking, an oil drain plug for oil changes and an air filter for aerating and ventilating the gear unit are provided. Colour codes for ventilating, oil inlet, oil level and oil drainage: Ventilating: yellow Oil inlet: yellow Oil level: red Lubrication points: red Oil drain: white For detailed view of the gear unit, the drawings in the gear-unit documentation must be observed. 5.3 Toothed components The toothed components of the gear unit are case-hardened. Helical-gear teeth are ground. The high quality of the teeth leads to significant noise reduction and ensures safe and reliable running. The gears are connected with the shafts by interference fits and parallel keys or by shrink fits. These types of joints transmit with adequate reliability the torques generated.Caution! BA 5 EN 1.0.4 Lubrication 5.4.1 Dip lubrication Unless otherwise stated in the order documentation, the teeth and bearings are adequately splash-lubricated with oil by the gearwheels. This means that the gear units require very littlemaintenance. 5.4.2 Pressure lubrication by external or ad| Model Type | Bevel-helical gear boxes B3 |

|---|---|

| Gear Type | Bevel Helical Gear |

| Weight (kg) | 900.000000 |

| Ratio Range | 1 : 12.5…71 |

| Low Speed Output | Solid shaft with parallel key acc. to DIN 6885/1 with reinforced spigot |

| Nominal Torque | 35700 Nm |

| Mounting Arrangements | Horizontal mounting position |

| Manufacturer | flanders electric peru s a c |

| Country of Manufacture | Germany |

| Data Sheet & Drawings | s H H H and H Shaft extension on both sides Gea B3-VH9-B Bevel-helical gear boxes B3 |