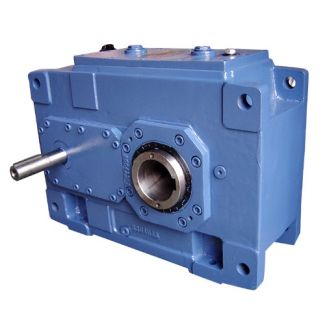

B3-VH20A MD Helical gear units vertical mounting positi Bevel-helical gear reducers B3

In stock

SKU

B3-VH20A

$173,571.43

Flender/Flender Gear Units/Bevel-helical gear reducers B3

ons between the tool and work piece. In gener- ating methods, the relative motions are based on basic rack with straight tooth proles meshing with the work piece. If the rack is replaced by hob, it is possibleto determine the

straight tooth proles meshing with the work piece. If the rack is replaced by hob, it is possibleto determine the  manufacturing motion which will replicate the motion of the rack. On bevel gears, the same principle applies. Instead of basic

manufacturing motion which will replicate the motion of the rack. On bevel gears, the same principle applies. Instead of basic  rack, virtual basic crown gear is used which, like the rack for cylindrical gears, has straight toothproles. Figure 3.5shows the

rack, virtual basic crown gear is used which, like the rack for cylindrical gears, has straight toothproles. Figure 3.5shows the  basic crown gear also termed generating gear in bevel gear manufacturing machine. The generating motion takes place when thecutter, rotating about its own axis, is simultaneously rotating about the axis of the generating gear while the work piece rotates about its own axis at given gear ratio with the generating gear. The generating gear can be at, as the one displayed inFig. 3.5, or take conical shape. For the different gear manufacturing methods described in Sect. 2.1, there are various ways in which cutter can be substituted to3.2 Manufacturing Kinematics 6 the relevant virtual generating gear. Figure 3.6, for example, represents the Spirac method in which conical generating gear, used for plunge cut wheel, is replaced by tilted face cutter. Determining the respective relative motions between the cutter and the bevel gear is therefore by no means trivial concern, particularly since additional motions are superimposed to modify and improve tooth ank topography. The following points will be noted with respect to the gear cutting machine: If, for example, tooth of the virtual crown gear is represented by the cutting edges of rotating cutter, the pitch plane of the cutter will usually be parallel to the pitch plane of the basic crown gear. However, in some manufacturing methods (see Table 2. the tool is tilted in order to modify the lengthwise crowning. If the aim is to increase lengthwise crowning, the cutter is tilted such that the tooth ends are cut deeper than in the middle

basic crown gear also termed generating gear in bevel gear manufacturing machine. The generating motion takes place when thecutter, rotating about its own axis, is simultaneously rotating about the axis of the generating gear while the work piece rotates about its own axis at given gear ratio with the generating gear. The generating gear can be at, as the one displayed inFig. 3.5, or take conical shape. For the different gear manufacturing methods described in Sect. 2.1, there are various ways in which cutter can be substituted to3.2 Manufacturing Kinematics 6 the relevant virtual generating gear. Figure 3.6, for example, represents the Spirac method in which conical generating gear, used for plunge cut wheel, is replaced by tilted face cutter. Determining the respective relative motions between the cutter and the bevel gear is therefore by no means trivial concern, particularly since additional motions are superimposed to modify and improve tooth ank topography. The following points will be noted with respect to the gear cutting machine: If, for example, tooth of the virtual crown gear is represented by the cutting edges of rotating cutter, the pitch plane of the cutter will usually be parallel to the pitch plane of the basic crown gear. However, in some manufacturing methods (see Table 2. the tool is tilted in order to modify the lengthwise crowning. If the aim is to increase lengthwise crowning, the cutter is tilted such that the tooth ends are cut deeper than in the middle| Model Type | Bevel-helical gear reducers B3 |

|---|---|

| Gear Type | Bevel Helical Gear |

| Weight (kg) | 8100.000000 |

| Ratio Range | 1 : 14…80 |

| Low Speed Output | Solid shaft with parallel key acc. to DIN 6885/1 with reinforced spigot |

| Nominal Torque | 345000 Nm |

| Mounting Arrangements | Horizontal mounting position |

| Manufacturer | Flender Himmel RSA |

| Country of Manufacture | Germany |

| Data Sheet & Drawings | B3-VH20A MD Helical gear units vertical mounting positi Bevel-helical gear reducers B3 |