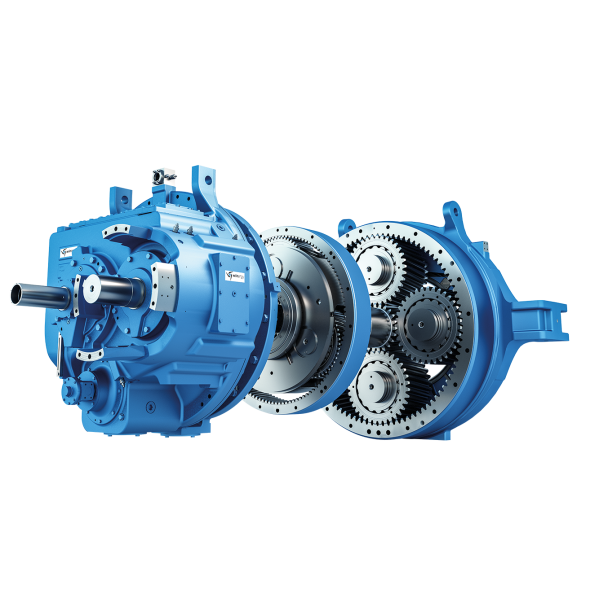

B3-KV-24-D ow speed shaft LSS Oil quantity B V Dip lubr Bevel-helical gear boxes B3

In stock

SKU

B3-KV-24-D

$287,142.86

Flender/Flender Gear Units/Bevel-helical gear boxes B3

s must be observed for relubrication of the lower bearing (see section 7, "Startup", and table 4 in section 1, "Maintenance and Repair"). Fig. 3: Oildam pipe 1 Oildam pipe 2 Lubricating point 4 / 1BA 5 en 0/2.8 Cooling

"Maintenance and Repair"). Fig. 3: Oildam pipe 1 Oildam pipe 2 Lubricating point 4 / 1BA 5 en 0/2.8 Cooling  Depending on requirement, the gear unit is fitted with fan, cooling coil, water or air oilcooling system or separate oilsupply

Depending on requirement, the gear unit is fitted with fan, cooling coil, water or air oilcooling system or separate oilsupply  system. In case of separate oilsupply system, the specific instructions for this oilsupply system must be observed. When installing the

system. In case of separate oilsupply system, the specific instructions for this oilsupply system must be observed. When installing the  gear unit free convection must be ensured on the housing surface, in order to definitely avoid overheating the gear unit. 5.8.1 Fan Installation of fan is possible only with type .. (bevelhelical gear unit). The fan is mounted on the highspeed shaft of the gear unit and is protected from accidental contact by an air guide cover. The fan sucks air through the grid of the air guide cover and blows it along the air ducts on the side of the gear housing. It thereby dissipates certain amount of heat from the housing. Fig. 3: Fan on gear unit of type .. 1 Fan 2 Air guide cover detailed view of the gear unit can be obtained from the drawings in the gearunit documentation. For gear units fitted with fan, sufficient space must be allowed for air intake when mounting the safety guards for the coupling or other components. The correct distance is given in the dimensioned drawing in the gearunitdocumentation. It must be ensured that the air guide cover is correctly fastened. The air guide cover must be protected against damage from outside. The fan must not come into contact with the air guide cover. The cooling effect is considerably reduced if the fan or the gear housing are dirty (see section 1, "Maintenance and repair"). 4 / 1BA 5 en 0/2.8.2 Cooling coil The gear unit can be fitted with cooling coil in the oil sump. Cooling water is supplied by way of water connection. The operator must ensure this. Either fresh water, sea water or brackish water can be used for cooling purposes. When wa

gear unit free convection must be ensured on the housing surface, in order to definitely avoid overheating the gear unit. 5.8.1 Fan Installation of fan is possible only with type .. (bevelhelical gear unit). The fan is mounted on the highspeed shaft of the gear unit and is protected from accidental contact by an air guide cover. The fan sucks air through the grid of the air guide cover and blows it along the air ducts on the side of the gear housing. It thereby dissipates certain amount of heat from the housing. Fig. 3: Fan on gear unit of type .. 1 Fan 2 Air guide cover detailed view of the gear unit can be obtained from the drawings in the gearunit documentation. For gear units fitted with fan, sufficient space must be allowed for air intake when mounting the safety guards for the coupling or other components. The correct distance is given in the dimensioned drawing in the gearunitdocumentation. It must be ensured that the air guide cover is correctly fastened. The air guide cover must be protected against damage from outside. The fan must not come into contact with the air guide cover. The cooling effect is considerably reduced if the fan or the gear housing are dirty (see section 1, "Maintenance and repair"). 4 / 1BA 5 en 0/2.8.2 Cooling coil The gear unit can be fitted with cooling coil in the oil sump. Cooling water is supplied by way of water connection. The operator must ensure this. Either fresh water, sea water or brackish water can be used for cooling purposes. When wa| Model Type | Bevel-helical gear boxes B3 |

|---|---|

| Gear Type | Bevel Helical Gear |

| Weight (kg) | 13400.000000 |

| Ratio Range | 1 : 22.4…80 |

| Low Speed Output | Hollow shaft with spline acc. to DIN 5480 |

| Nominal Torque | 725000 Nm |

| Mounting Arrangements | Vertical mounting position |

| Manufacturer | Flender Singapore Pte. Ltd. |

| Country of Manufacture | Algeria |

| Data Sheet & Drawings | B3-KV-24-D ow speed shaft LSS Oil quantity B V Dip lubr Bevel-helical gear boxes B3 |