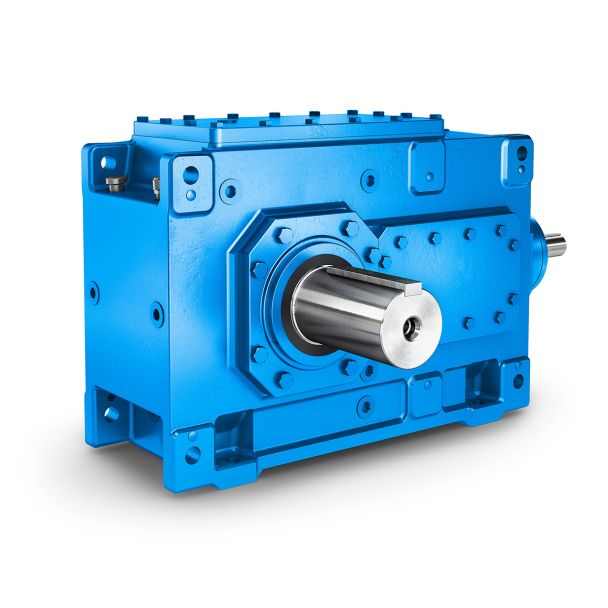

B3-KV25A i cationOil quantity B V Forced lubrica tion Bevel-helical gear reducers B3

In stock

SKU

B3-KV25A

$345,000.00

Flender/Flender Gear Units/Bevel-helical gear reducers B3

s must not be pinched or Binding. Adjust to correct end float.All shafts must spin freely whendisconnected from load. ------------------------------------------------------------------------------------------------------ --- Bredgar Road, Gillingham, Kent, ME8 6PN Tel: 0 3 .Price: sales Siemens Flender mixertech.co.ukFax: 0 3 Internet: Germany mixertech.co.uk

--- Bredgar Road, Gillingham, Kent, ME8 6PN Tel: 0 3 .Price: sales Siemens Flender mixertech.co.ukFax: 0 3 Internet: Germany mixertech.co.uk  _______________________________________________________________________________ Problem : Mixer vibrates or is rocking - becaus mixer is rotating equipment it will vibrate and rock. However,

_______________________________________________________________________________ Problem : Mixer vibrates or is rocking - becaus mixer is rotating equipment it will vibrate and rock. However,  excessive mo vement is detrimental to the equipment and could cause premature failure. ------------------------------------------------------------------------------------------------------ Inspection Action ------------------------------------------------------------------------------------------------------ Check Impellers Tighten

excessive mo vement is detrimental to the equipment and could cause premature failure. ------------------------------------------------------------------------------------------------------ Inspection Action ------------------------------------------------------------------------------------------------------ Check Impellers Tighten  bolts if required. Check for correct installation. Check holding down bolts. Tighten bolts on mixer bridge and baseplate. Check foundation steelwork Sti ffen or brace steelwork. Check shaft. Is it straight? Is it vertical? Drop plumbline from coupling. Check output coupling Is it fitted correctly? Remove burrs And sharp edges - tighten couplingbolts. Critical speed Refer to supply for design calculations. Reduce speed to 3% below critical speed. Steady bearing (if fitted) Check for wear and for slack bolts.Liquid level Is mixer designed to operate at varying liquid levels. Check stabilizers onblades. Limit variation. ------------------------------------------------------------------------------------------------------ --- Bredgar Road, Gillingham, Kent, ME8 6PN Tel: 0 3 .Price: sales Siemens Flender mixertech.co.ukFax: 0 3 Internet: Germany mixertech.co.uk _______________________________________________________________________________ Problem: Mixer makes noise - mixer is ro

bolts if required. Check for correct installation. Check holding down bolts. Tighten bolts on mixer bridge and baseplate. Check foundation steelwork Sti ffen or brace steelwork. Check shaft. Is it straight? Is it vertical? Drop plumbline from coupling. Check output coupling Is it fitted correctly? Remove burrs And sharp edges - tighten couplingbolts. Critical speed Refer to supply for design calculations. Reduce speed to 3% below critical speed. Steady bearing (if fitted) Check for wear and for slack bolts.Liquid level Is mixer designed to operate at varying liquid levels. Check stabilizers onblades. Limit variation. ------------------------------------------------------------------------------------------------------ --- Bredgar Road, Gillingham, Kent, ME8 6PN Tel: 0 3 .Price: sales Siemens Flender mixertech.co.ukFax: 0 3 Internet: Germany mixertech.co.uk _______________________________________________________________________________ Problem: Mixer makes noise - mixer is ro| Model Type | Bevel-helical gear reducers B3 |

|---|---|

| Gear Type | Bevel Helical Gear |

| Weight (kg) | 16100.000000 |

| Ratio Range | 1 : 20…71 |

| Low Speed Output | Hollow shaft with spline acc. to DIN 5480 |

| Nominal Torque | 860000 Nm |

| Mounting Arrangements | Vertical mounting position |

| Manufacturer | Beijing Flender |

| Country of Manufacture | China |

| Data Sheet & Drawings | B3-KV25A i cationOil quantity B V Forced lubrica tion Bevel-helical gear reducers B3 |