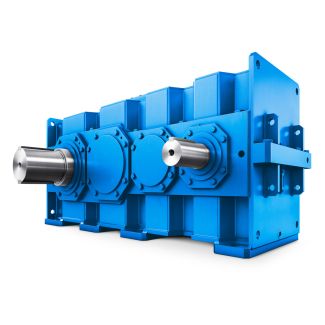

B3-KH-5-D supplement for th to th position see pages t Bevel-helical speed reducers B3

In stock

SKU

B3-KH-5-D

$12,000.00

Flender/Flender Gear Units/Bevel-helical speed reducers B3

RN (. Interaction of carbon dioxide and oxygen levels, and temperature on adult survival and multiplication of Cryptolestes ferrugineus (Coleoptera: Cu- cujidae) in stored wheat. Phytoprotection 6:3. White NDG, Jayas DS, Sinha RN (. Carbon dioxide as control agent for

Cu- cujidae) in stored wheat. Phytoprotection 6:3. White NDG, Jayas DS, Sinha RN (. Carbon dioxide as control agent for  the rusty grain beetle (Coleoptera: Cucujidae) in stored wheat. Econ Entomol 8:2. White NDG, Sinha RN, Muir WE (. Intergranular

the rusty grain beetle (Coleoptera: Cucujidae) in stored wheat. Econ Entomol 8:2. White NDG, Sinha RN, Muir WE (. Intergranular  carbon dioxide as an indicator of biological activity associated with the spoilage of stored wheat. Can Agric Eng 2:3. White

carbon dioxide as an indicator of biological activity associated with the spoilage of stored wheat. Can Agric Eng 2:3. White  NDG, Sinha RN, Jayas DS, Muir WE (. Movement of Cryptolestes ferrugineus (Col- eoptera: Cucujidae) through carbon dioxide gradients in stored wheat. Econ Entomol 8: 1. Willis ER, Roth LM (. Reactions of our beetles of the genus Tribolium to carbon dioxide and air. Exp Zool 1:1. Grain-Milling Operations ASHOK . SARKAR Canadian International Grains Institute, Winnipeg, Manitoba, Canada 1 EVOLUTION OF GRAIN MILLING The rst step between postharvest of cereals and nished, processed cereal-based foods is the milling operation. The history of milling operations is very rich and as old as human civilization. Historians have considered the level of milling technology as an indicator ofthe development of given civilization at that point in time. Figure 1 provides chronological illustration of the development of all forms of grain-milling equipment and the time periods during which they were developed and wereoperational. Although the milling tools and the processes have changed radically, the basic purpose of milling remains essentially the sameto improve palatibility and digestibility of the grain. The development of the grain-milling operation in its present form is primarily be- cause of the following reasons: 1. Economies of scale 2. Need for improved product quality 3. Wider product range Most grain-milling facilities built today would include high degree of automation allowing process monitoring and control through the application of progr

NDG, Sinha RN, Jayas DS, Muir WE (. Movement of Cryptolestes ferrugineus (Col- eoptera: Cucujidae) through carbon dioxide gradients in stored wheat. Econ Entomol 8: 1. Willis ER, Roth LM (. Reactions of our beetles of the genus Tribolium to carbon dioxide and air. Exp Zool 1:1. Grain-Milling Operations ASHOK . SARKAR Canadian International Grains Institute, Winnipeg, Manitoba, Canada 1 EVOLUTION OF GRAIN MILLING The rst step between postharvest of cereals and nished, processed cereal-based foods is the milling operation. The history of milling operations is very rich and as old as human civilization. Historians have considered the level of milling technology as an indicator ofthe development of given civilization at that point in time. Figure 1 provides chronological illustration of the development of all forms of grain-milling equipment and the time periods during which they were developed and wereoperational. Although the milling tools and the processes have changed radically, the basic purpose of milling remains essentially the sameto improve palatibility and digestibility of the grain. The development of the grain-milling operation in its present form is primarily be- cause of the following reasons: 1. Economies of scale 2. Need for improved product quality 3. Wider product range Most grain-milling facilities built today would include high degree of automation allowing process monitoring and control through the application of progr| Model Type | Bevel-helical speed reducers B3 |

|---|---|

| Gear Type | Bevel Helical Gear |

| Weight (kg) | 560.000000 |

| Ratio Range | 1 : 12.5…71 |

| Low Speed Output | Hollow shaft with spline acc. to DIN 5480 |

| Nominal Torque | 11600 Nm |

| Mounting Arrangements | Horizontal mounting position |

| Manufacturer | PT Flenindo Aditransimisi |

| Country of Manufacture | United Arab Emirates |

| Data Sheet & Drawings | B3-KH-5-D supplement for th to th position see pages t Bevel-helical speed reducers B3 |