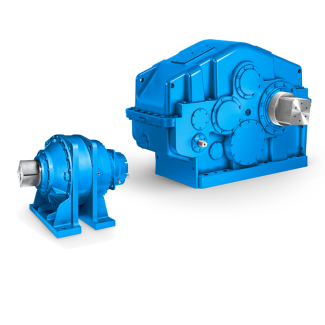

B3-KH-10-D nce mm Flender GmbH Flender MD Bevel helic Bevel-helical gear reducer B3

In stock

SKU

B3-KH-10-D

$19,928.57

Flender/Flender Gear Units/Bevel-helical gear reducer B3

rollers, in addition to the weight. Assum ing that the load in the cylinder is non- solid and tends to remain essen tially central (or balanced). The Table below lists angle factors to be used in the calculations. Table 2.

remain essen tially central (or balanced). The Table below lists angle factors to be used in the calculations. Table 2.  Angle Factors For Roller Supported Cylinders Angle 0 2 4 5 6 7 8 9 Angle Factor 1.0 1.0 1.0

Angle Factors For Roller Supported Cylinders Angle 0 2 4 5 6 7 8 9 Angle Factor 1.0 1.0 1.0  1.1 1.1 1.2 1.3 1.4The friction force acts at the point of contact between the rollers and the cylinder, and

1.1 1.1 1.2 1.3 1.4The friction force acts at the point of contact between the rollers and the cylinder, and  will be: Friction Force=(Weight)(Friction Factor)(Angle Factor) Assuming the cylinder is to be driven by one of the rollers: Torque = (Friction Force) (Radius of Roller) Example : 1 Lb. steel cylinder is resting on two pairs of steel rollers which are 4 in diameter. The cylinder is empty. The angle between rollers is 5. How much torque is required at the roller to turn the cylinder? Select 1.1 as Angle Factor (Table , and .0 as Rolling Friction Factor (Table . Determine Friction Force: 1 .0 1.1 = 3 Lbs. Determine Torque: 3 2 = 6 Lb. Ins. Horizontal Axis Supported cylinders (Figure , with unbal anced loads require different approach. Assuming that the cylinder is not full, and that the material is rotated to position about 4 from the vertical, the torque is equal to the Material Weight Effective Radius. Effective Radius = Cylinder Diameter () 0.2 (1/4 full) 0.1 (1/2 full) 0.0 (3/4 full) Example : An axis supported cylinder is 3 Ft. in diameter and is half full of semi-solids mixture weighing 4 Lbs. How much torque is required (at the axis) to rotate the cylinder? Determine the Effective Radius: .1 (3 = 5.4 In. Calculate Torque: 4 5.4 = 2 Lb. Ins.ROLLER ANGLE WG.0WG.0RADIUSRADIUS ANGLE WG.0 Figure 1Figure 2 FLENDER GRAFFENSTADEN bostongear speed reducers -1-BG 5/1QApplication Considerations Turntables Here, too, turntable applications appear to lend themselves to overspecification of the speed reducer. This type of problem involves rotation of weight in horizontal plane, and in most cases the torque must only overc

will be: Friction Force=(Weight)(Friction Factor)(Angle Factor) Assuming the cylinder is to be driven by one of the rollers: Torque = (Friction Force) (Radius of Roller) Example : 1 Lb. steel cylinder is resting on two pairs of steel rollers which are 4 in diameter. The cylinder is empty. The angle between rollers is 5. How much torque is required at the roller to turn the cylinder? Select 1.1 as Angle Factor (Table , and .0 as Rolling Friction Factor (Table . Determine Friction Force: 1 .0 1.1 = 3 Lbs. Determine Torque: 3 2 = 6 Lb. Ins. Horizontal Axis Supported cylinders (Figure , with unbal anced loads require different approach. Assuming that the cylinder is not full, and that the material is rotated to position about 4 from the vertical, the torque is equal to the Material Weight Effective Radius. Effective Radius = Cylinder Diameter () 0.2 (1/4 full) 0.1 (1/2 full) 0.0 (3/4 full) Example : An axis supported cylinder is 3 Ft. in diameter and is half full of semi-solids mixture weighing 4 Lbs. How much torque is required (at the axis) to rotate the cylinder? Determine the Effective Radius: .1 (3 = 5.4 In. Calculate Torque: 4 5.4 = 2 Lb. Ins.ROLLER ANGLE WG.0WG.0RADIUSRADIUS ANGLE WG.0 Figure 1Figure 2 FLENDER GRAFFENSTADEN bostongear speed reducers -1-BG 5/1QApplication Considerations Turntables Here, too, turntable applications appear to lend themselves to overspecification of the speed reducer. This type of problem involves rotation of weight in horizontal plane, and in most cases the torque must only overc| Model Type | Bevel-helical gear reducer B3 |

|---|---|

| Gear Type | Bevel Helical Gear |

| Weight (kg) | 930.000000 |

| Ratio Range | 1 : 16…90 |

| Low Speed Output | Hollow shaft with spline acc. to DIN 5480 |

| Nominal Torque | 43800 Nm |

| Mounting Arrangements | Horizontal mounting position |

| Manufacturer | Siemens Flender |

| Country of Manufacture | Armenia |

| Data Sheet & Drawings | B3-KH-10-D nce mm Flender GmbH Flender MD Bevel helic Bevel-helical gear reducer B3 |