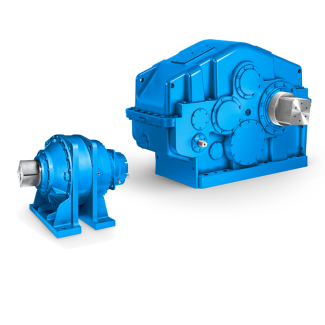

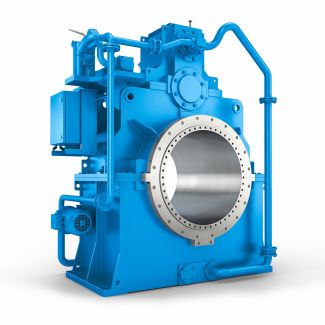

B3KH-11-C to Selection and ordering data continued Low sp Bevel-helical gear Reduction Box B3

In stock

SKU

B3KH-11-C

$40,285.71

Flender/Flender Gear Units/Bevel-helical gear Reduction Box B3

rom evaporators near the ceiling travels across the top and between containers beforereturning to the evaporator. An airow of at least 1 to 2 /H1is needed to remove eld heat effectively ( and should be reduced to 0.0 to 0.1

least 1 to 2 /H1is needed to remove eld heat effectively ( and should be reduced to 0.0 to 0.1  /H1for subsequent storage to prevent excessive moisture loss thereafter (. It is possible to achieve better air distri-bution with several

/H1for subsequent storage to prevent excessive moisture loss thereafter (. It is possible to achieve better air distri-bution with several  small evaporators evenly spaced along one wall than with one largeevaporator (. The pallet bins should be stacked in manner

small evaporators evenly spaced along one wall than with one largeevaporator (. The pallet bins should be stacked in manner  that ensures that the cold air has good contact with all surfaces of the bins. Poor contact may not cool the produce in the center of the bin as rapidly as desired (. Space should be left between all binsand the bins should be oriented so that the openings for forklifts run in the same directionas the airow. 5 Rennie et al. The type of packaging has an effect on the rate at which the produce cools. Cooling time can be reduced by providing ventilation in the containers. For example, side ventingarea of 5% on boxes can reduce the cooling time by 2% compared to that of similarcontainers that are not vented (. However, the addition of venting to containers de-creases their stacking strength, depending on the size and location of the vents. Using 5% venting area reduces the berboard container strength by 2%3% as long as the vents are not situated in the corners (. The shape and size of the vents should not allow likelyblocking of the vents by the produce within. It is more efcient to use few large ventsthan numerous small vents (. Plastic containers do not have this disadvantage of loststrength and can be designed to support the load of produce with up to 2% of the containersurface area dedicated to venting (. Good room management can increase the rate of cooling of the produce. Gradually lling up the room with produce can result in shorter cooling time than lling the roomquickly. The lower cooling rate is result of reduced eld heat removal at any given time. For exampl

that ensures that the cold air has good contact with all surfaces of the bins. Poor contact may not cool the produce in the center of the bin as rapidly as desired (. Space should be left between all binsand the bins should be oriented so that the openings for forklifts run in the same directionas the airow. 5 Rennie et al. The type of packaging has an effect on the rate at which the produce cools. Cooling time can be reduced by providing ventilation in the containers. For example, side ventingarea of 5% on boxes can reduce the cooling time by 2% compared to that of similarcontainers that are not vented (. However, the addition of venting to containers de-creases their stacking strength, depending on the size and location of the vents. Using 5% venting area reduces the berboard container strength by 2%3% as long as the vents are not situated in the corners (. The shape and size of the vents should not allow likelyblocking of the vents by the produce within. It is more efcient to use few large ventsthan numerous small vents (. Plastic containers do not have this disadvantage of loststrength and can be designed to support the load of produce with up to 2% of the containersurface area dedicated to venting (. Good room management can increase the rate of cooling of the produce. Gradually lling up the room with produce can result in shorter cooling time than lling the roomquickly. The lower cooling rate is result of reduced eld heat removal at any given time. For exampl| Model Type | Bevel-helical gear Reduction Box B3 |

|---|---|

| Gear Type | Bevel Helical Gear |

| Weight (kg) | 1880.000000 |

| Ratio Range | 1 : 12.5…71 |

| Low Speed Output | Hollow shaft with spline acc. to DIN 5480 |

| Nominal Torque | 63500 Nm |

| Mounting Arrangements | Horizontal mounting position |

| Manufacturer | FLENDER TÜBINGEN GMBH |

| Country of Manufacture | Austria |

| Data Sheet & Drawings | B3KH-11-C to Selection and ordering data continued Low sp Bevel-helical gear Reduction Box B3 |