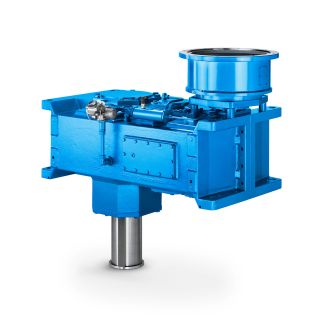

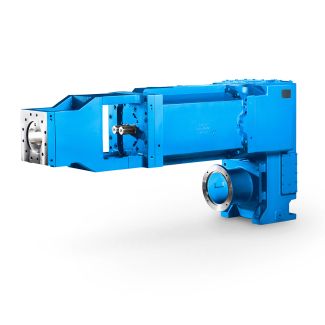

fts The slow speed hollow shaft H hollow shaft wi B3-HV-12B Bevel-helical gear boxes B3

In stock

SKU

B3-HV-12B

$40,714.29

Flender/Flender Gear Units/Bevel-helical gear boxes B3

r determines the taste of rice by detecting the amount of starches, proteins, degree of fat acidication, and moisture content of milled rice. near-infrared analyzer is used for the quantitative assessment. The rice taste analyzer that is commonlyused in Japan

of milled rice. near-infrared analyzer is used for the quantitative assessment. The rice taste analyzer that is commonlyused in Japan  is shown in Fig. 2. 4 CONCLUSION Quality standards for milled rice will continue to be improved. In addition, customers

is shown in Fig. 2. 4 CONCLUSION Quality standards for milled rice will continue to be improved. In addition, customers  in the near future will demand more than merely rice with specic appearance. Futuremilling systems may also require the capability

in the near future will demand more than merely rice with specic appearance. Futuremilling systems may also require the capability  to control, to one degree or another, suchcharacteristics as water absorption rate, surface texture, and protein content. Because ofthis, rice mills will continually have to adopt advanced milling technology. In such an environment, it will be their knowledge of rice-milling technology that separates one company from another. Rice mill management will have to be familiar, to an increasingly greater degree, with the technological advancements that are being offeredto the industry. REFERENCES 1. Satake (. Modern Rice-Milling Technology. University of Tokyo Press, Tokyo. 2. Bond (. Presentation to the Satake USA Milling College. 3. Kanemoto (. Research on Rice Milling and Process Technologies. Dehulling and Splitting Pulses SHAHAB SOKHANSANJ University of Saskatchewan, Saskatoon, Saskatchewan, Canada RHAMBO . PATIL Central Institute for Agricultural Engineering, Bhopal, India 1 INTRODUCTION Pulses are part of the legumes, family of plants that have the unique characteristic of hosting symbiotic bacteria that atmospheric nitrogen in the plant roots. This not onlyreduces fertilizer requirements, but also improves soil structure. Pulses provide green pods for vegetables and nutritious fodder for cattle because they are rich in protein and in the essential amino acid lysine . Dry pulses are also major food staple of populations in India, the Middle East, Africa, and South America. The response to diversication of agriculture from conventional crops to puls

to control, to one degree or another, suchcharacteristics as water absorption rate, surface texture, and protein content. Because ofthis, rice mills will continually have to adopt advanced milling technology. In such an environment, it will be their knowledge of rice-milling technology that separates one company from another. Rice mill management will have to be familiar, to an increasingly greater degree, with the technological advancements that are being offeredto the industry. REFERENCES 1. Satake (. Modern Rice-Milling Technology. University of Tokyo Press, Tokyo. 2. Bond (. Presentation to the Satake USA Milling College. 3. Kanemoto (. Research on Rice Milling and Process Technologies. Dehulling and Splitting Pulses SHAHAB SOKHANSANJ University of Saskatchewan, Saskatoon, Saskatchewan, Canada RHAMBO . PATIL Central Institute for Agricultural Engineering, Bhopal, India 1 INTRODUCTION Pulses are part of the legumes, family of plants that have the unique characteristic of hosting symbiotic bacteria that atmospheric nitrogen in the plant roots. This not onlyreduces fertilizer requirements, but also improves soil structure. Pulses provide green pods for vegetables and nutritious fodder for cattle because they are rich in protein and in the essential amino acid lysine . Dry pulses are also major food staple of populations in India, the Middle East, Africa, and South America. The response to diversication of agriculture from conventional crops to puls| Model Type | Bevel-helical gear boxes B3 |

|---|---|

| Gear Type | Bevel Helical Gear |

| Weight (kg) | 1900.000000 |

| Ratio Range | 1 : 16…90 |

| Low Speed Output | Hollow shaft with keyway acc. to DIN 6885/1 |

| Nominal Torque | 77200 Nm |

| Mounting Arrangements | Vertical mounting position |

| Manufacturer | Flender de Mexico, S.A. de C.V. |

| Country of Manufacture | Germany |

| Data Sheet & Drawings | fts The slow speed hollow shaft H hollow shaft wi B3-HV-12B Bevel-helical gear boxes B3 |