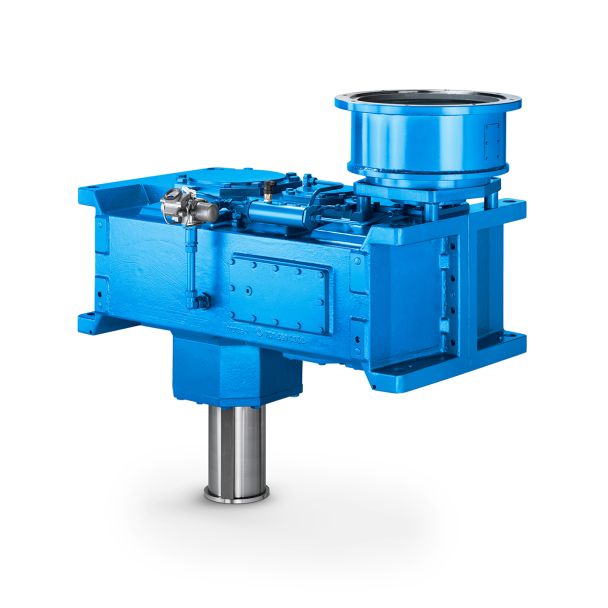

mbH Flender MD Helical gear units vertical mo B3-HH-14-D Bevel-helical gear Reduction Boxes B3

In stock

SKU

B3-HH-14-D

$58,928.57

Flender/Flender Gear Units/Bevel-helical gear Reduction Boxes B3

production is to be rationalised and automated, and the waste water situation im- proved. 2. Working steps At the outset, the optimum feed ressure and time have to be determined on soaked and fleshed sheep,goatand otherfursk, using the feed unitdevelopedforleatherproduction,in

the optimum feed ressure and time have to be determined on soaked and fleshed sheep,goatand otherfursk, using the feed unitdevelopedforleatherproduction,in  order to obtain uniform and constant diffusion and distribution of the liquids fed in. Given the knowledge of these parameters,

order to obtain uniform and constant diffusion and distribution of the liquids fed in. Given the knowledge of these parameters,  the pickling, chrome tanning,aluminium tanning and stuffing processes are carried out systematically, although variations in the quantity and type of

the pickling, chrome tanning,aluminium tanning and stuffing processes are carried out systematically, although variations in the quantity and type of  chemi- cals used can be made in these processes. Based on the results, comparisons are then made between conventionally processed furs and those produced by the feeding technique in order to determine if there are any differences in quality. 3. Results This technique was used in fur production, after the leather production ex eriments showed that feeding liquids under pressure from the flesh side runs smoothly, yielg good results and brings about considerable improvements as re ards the waste water. The initial ex eriments were dedicated to determining the optimum vayues for the feed pressure and time Kr various skins, such as shee , goat and Persian lamb. These experiments showed that the pressure should be2 -3 barkrsheepand Persian lambskins,and4-5 barforgoatskins.ln contrast,the feed time was 1 - 1 seconds for all untreated skins, depending on the thickness of the skin. At the same time, it was determined in the course of the experiments that these optimum fac- tors could be used for the pickling, tanning and stuffing processes and that no change was necessary. In the case of pickling, itwas observed that formicacid ielded the best results, .. that macera- tion with formicacid resulted in the most uniform and ivourable prerequisitesfor subsequent tanning with mineral tanning agents or aldehydes. This was also true for all untreated skins used. For chrome tanning, the best results were obtain

chemi- cals used can be made in these processes. Based on the results, comparisons are then made between conventionally processed furs and those produced by the feeding technique in order to determine if there are any differences in quality. 3. Results This technique was used in fur production, after the leather production ex eriments showed that feeding liquids under pressure from the flesh side runs smoothly, yielg good results and brings about considerable improvements as re ards the waste water. The initial ex eriments were dedicated to determining the optimum vayues for the feed pressure and time Kr various skins, such as shee , goat and Persian lamb. These experiments showed that the pressure should be2 -3 barkrsheepand Persian lambskins,and4-5 barforgoatskins.ln contrast,the feed time was 1 - 1 seconds for all untreated skins, depending on the thickness of the skin. At the same time, it was determined in the course of the experiments that these optimum fac- tors could be used for the pickling, tanning and stuffing processes and that no change was necessary. In the case of pickling, itwas observed that formicacid ielded the best results, .. that macera- tion with formicacid resulted in the most uniform and ivourable prerequisitesfor subsequent tanning with mineral tanning agents or aldehydes. This was also true for all untreated skins used. For chrome tanning, the best results were obtain| Model Type | Bevel-helical gear Reduction Boxes B3 |

|---|---|

| Gear Type | Bevel Helical Gear |

| Weight (kg) | 2750.000000 |

| Ratio Range | 1 : 16…90 |

| Low Speed Output | Hollow shaft with keyway acc. to DIN 6885/1 |

| Nominal Torque | 113000 Nm |

| Mounting Arrangements | Horizontal mounting position |

| Manufacturer | Flender Power Transmission Inc. |

| Country of Manufacture | North Macedonia |

| Data Sheet & Drawings | mbH Flender MD Helical gear units vertical mo B3-HH-14-D Bevel-helical gear Reduction Boxes B3 |