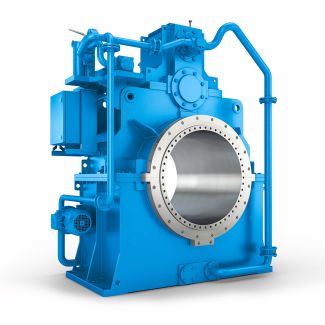

data continued Low speed shaft LSS Oil quantity B3-HH-8B Bevel-helical gearbox B3

In stock

SKU

B3-HH-8B

$17,142.86

Flender/Flender Gear Units/Bevel-helical gearbox B3

pply system. Protect gear unit with suitable heat insulation.Close air outlet or alter its directionby structural measures. Contact Customer Service. If necessary, fit wet-air filter. Operating temperature too high.Oil level in housing too high. Oil too old. Oil badly contaminated.

If necessary, fit wet-air filter. Operating temperature too high.Oil level in housing too high. Oil too old. Oil badly contaminated.  Defective oil-supply unit or cooling coil.Check oil level and, if necessary, adjust. Check date of last oil change and, if

Defective oil-supply unit or cooling coil.Check oil level and, if necessary, adjust. Check date of last oil change and, if  necessary, change oil.See section 1. Change oil. See section 1. Check the oil supply system / cooling coil, replace anydefective

necessary, change oil.See section 1. Change oil. See section 1. Check the oil supply system / cooling coil, replace anydefective  parts.Consult operating instructionsfor oil supply system. Fault in oil supply system. Consult operating instructions for oil supply system. Table 9.1: Faults, causes and remedies 1. Maintenance and repair Observe the Safety instructions in section 3 and the instructions in section 9, Faults, causes and remedy. 1.1 General notes on maintenance Maintenance and repair work must be done with care by trained and qualified personnel only. The following applies to all work in item 1.2: Switch gear unit and add-on components off. Secure the drive unit to prevent it from being started up unintentionally. Attach warning notice to the start switch! The periods indicated in table 1.1 depend on the conditions under which the gear unit is operated. Only average periods can therefore be stated here. These refer to: daily operating time of 2 duty factor of 1 %Operating temperature of 7 (mineral oil only)Caution! BA 5 EN 1.0Measures Periods Remarks Checking oil temperature. daily Checking for unusual gear-unit noise.daily Checking oil level. monthly Checking gear unit for leaks. monthly Testing oil for water content. after approx. 4 operating hours,once per year at least see Item 1.2.1 First oil change after start-up. after approx. 4 operating hours see Item 1.2.2 Subsequent oil changes. every 2 months or1 0 operating hours see Item 1.2.2 Cleaning air filter. every 3 months see Item 1.2.3 Cleaning gear-unit housing. simultaneously with

parts.Consult operating instructionsfor oil supply system. Fault in oil supply system. Consult operating instructions for oil supply system. Table 9.1: Faults, causes and remedies 1. Maintenance and repair Observe the Safety instructions in section 3 and the instructions in section 9, Faults, causes and remedy. 1.1 General notes on maintenance Maintenance and repair work must be done with care by trained and qualified personnel only. The following applies to all work in item 1.2: Switch gear unit and add-on components off. Secure the drive unit to prevent it from being started up unintentionally. Attach warning notice to the start switch! The periods indicated in table 1.1 depend on the conditions under which the gear unit is operated. Only average periods can therefore be stated here. These refer to: daily operating time of 2 duty factor of 1 %Operating temperature of 7 (mineral oil only)Caution! BA 5 EN 1.0Measures Periods Remarks Checking oil temperature. daily Checking for unusual gear-unit noise.daily Checking oil level. monthly Checking gear unit for leaks. monthly Testing oil for water content. after approx. 4 operating hours,once per year at least see Item 1.2.1 First oil change after start-up. after approx. 4 operating hours see Item 1.2.2 Subsequent oil changes. every 2 months or1 0 operating hours see Item 1.2.2 Cleaning air filter. every 3 months see Item 1.2.3 Cleaning gear-unit housing. simultaneously with| Model Type | Bevel-helical gearbox B3 |

|---|---|

| Gear Type | Bevel Helical Gear |

| Weight (kg) | 800.000000 |

| Ratio Range | 1 : 16…90 |

| Low Speed Output | Hollow shaft with keyway acc. to DIN 6885/1 |

| Nominal Torque | 27200 Nm |

| Mounting Arrangements | Horizontal mounting position |

| Manufacturer | FLENOER-GRAFFENSTA |

| Country of Manufacture | Kyrgyzstan |

| Data Sheet & Drawings | data continued Low speed shaft LSS Oil quantity B3-HH-8B Bevel-helical gearbox B3 |