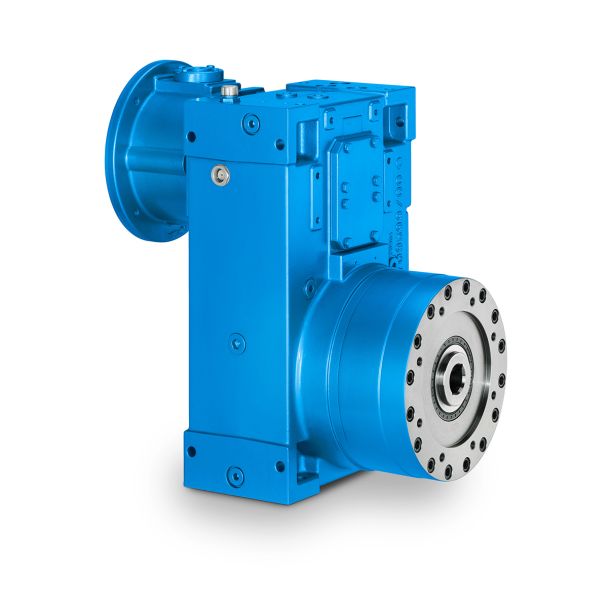

H Flender MD Bevel helical gear units vertica B3-FV-27-D Bevel-helical speed reduction gearbox B3

In stock

SKU

B3-FV-27-D

$488,571.43

Flender/Flender Gear Units/Bevel-helical speed reduction gearbox B3

sists of aslightly inclined cylinder, lined with rebricks, into which air is injected tangentially athigh velocity. The fuel introduced at one end is entrained by the revolving mass and is thrown against the cyclone walls, where it mixes intimately with

one end is entrained by the revolving mass and is thrown against the cyclone walls, where it mixes intimately with  air and burns. As result, in cyclone furnace combustion occurs in comparatively short space, where the owconditions can be controlled

air and burns. As result, in cyclone furnace combustion occurs in comparatively short space, where the owconditions can be controlled  and adjusted from outside. The ue gas, which leaves throughthe aperture at the other end of the cyclone, is quite

and adjusted from outside. The ue gas, which leaves throughthe aperture at the other end of the cyclone, is quite  free of ash (. In horizontal cyclone furnace, length-to-diameter ratio of 1:1.3 is normally main- tained. Cyclones are designed for positive-pressure operation. Generally cyclones requirean air blower with high static pressure. The schematics of some cyclone furnaces are shown in Fig. 2. 3.2.4 Furnace DesignThe values of thermal load of the furnace grate area and thermal load of the furnace volume are important for the design of furnace. Conversion and Utilization of Biomass 8 Fig. 2 Schematics of different cyclone furnaces. The thermal load of the furnace grate area is the amount of heat energy generated by complete combustion of solid fuel on unit area of re grate in unit time. The thermal load of the furnace volume is the amount of heat energy generated by complete combustion of solid fuel in unit volume of the furnace in unit time. Accordingly, the following mathematical expressions can be obtained directly. qA/H1WFCN ( and qV/H1WFCN ( where qA/H1thermal load of furnace grate area, kW/m2,qV/H1thermal load of furnace volume (kW/m,WF/H1rate of fuel burned (kg/), CN/H1net caloric value of the fuel (kJ/kg), /H1furnace grate area (m, and /H1volume of furnace (m. The thermal load of the furnace grate area and the thermal load of the furnace volume for rice husk fuels are about 2.6 kW/m2and 1.5 kW/m3, respectively. As result of various kinds of losses the amount of heat contained in the fuel gas leaving the furnace is less than that in the fuel charged.

free of ash (. In horizontal cyclone furnace, length-to-diameter ratio of 1:1.3 is normally main- tained. Cyclones are designed for positive-pressure operation. Generally cyclones requirean air blower with high static pressure. The schematics of some cyclone furnaces are shown in Fig. 2. 3.2.4 Furnace DesignThe values of thermal load of the furnace grate area and thermal load of the furnace volume are important for the design of furnace. Conversion and Utilization of Biomass 8 Fig. 2 Schematics of different cyclone furnaces. The thermal load of the furnace grate area is the amount of heat energy generated by complete combustion of solid fuel on unit area of re grate in unit time. The thermal load of the furnace volume is the amount of heat energy generated by complete combustion of solid fuel in unit volume of the furnace in unit time. Accordingly, the following mathematical expressions can be obtained directly. qA/H1WFCN ( and qV/H1WFCN ( where qA/H1thermal load of furnace grate area, kW/m2,qV/H1thermal load of furnace volume (kW/m,WF/H1rate of fuel burned (kg/), CN/H1net caloric value of the fuel (kJ/kg), /H1furnace grate area (m, and /H1volume of furnace (m. The thermal load of the furnace grate area and the thermal load of the furnace volume for rice husk fuels are about 2.6 kW/m2and 1.5 kW/m3, respectively. As result of various kinds of losses the amount of heat contained in the fuel gas leaving the furnace is less than that in the fuel charged.| Model Type | Bevel-helical speed reduction gearbox B3 |

|---|---|

| Gear Type | Bevel Helical Gear |

| Weight (kg) | 22800.000000 |

| Ratio Range | 1 : 20…71 |

| Low Speed Output | Flanged shaft |

| Nominal Torque | 1230000 Nm |

| Mounting Arrangements | Vertical mounting position |

| Manufacturer | Flender Ibérica S.A. |

| Country of Manufacture | Grenada |

| Data Sheet & Drawings | H Flender MD Bevel helical gear units vertica B3-FV-27-D Bevel-helical speed reduction gearbox B3 |