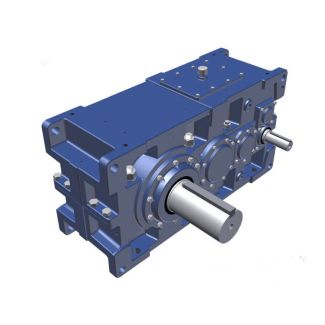

quantity B V Dip lubri cationOil quantity B V B3-FV-28-D Bevel-helical gear boxes B3

In stock

SKU

B3-FV-28-D

$550,714.29

Flender/Flender Gear Units/Bevel-helical gear boxes B3

size as describedpreviously. This grading part will be described very shortly in more detail. The break stock is fed to the next break-grinding passage in sequence through spout connected from the sifter outlet to the inlet of the second break

the next break-grinding passage in sequence through spout connected from the sifter outlet to the inlet of the second break  roll-grinding passage. In the second break passage the same function is repeated as more endosperm is releasedgradually and more of

roll-grinding passage. In the second break passage the same function is repeated as more endosperm is releasedgradually and more of  the released material is graded according to particle size to createsegregation, as described in the foregoing list. The break stock

the released material is graded according to particle size to createsegregation, as described in the foregoing list. The break stock  from second break reachesthe third break-grinding passage where similar action is repeated and more endosperm isreleased and graded. The break stock that reaches the fourth and fth break, if the latter are used, would have very little endosperm remaining on the bran akes as most of it would already have been extracted and graded. Therefore, the purpose of the last break-grinding passage might be described as cleaning up the bran before it moves on to amachine commonly known as bran duster or nisher. This particular machine removesthe last traces of the endosperm that still adheres to the bran. There are two different sizesof bran that are produced. The coarse bran is referred to as bran, while the ne bran isreferred to as shorts. Both of these are passed through separate dusters: namely, bran duster and shorts duster. Thus, although very gradual breaking and releasing of the endosperm from wheat and subsequent break stocks is desired, at the same time millerhas to ensure that all the endosperm is released and the bran is cleaned up, using theavailable four or ve break passages and bran duster, before dispatching the bran to thebran bin. 2 Sarkar 3.3.7.2 Grading of the Released Endosperm and Purication 3.3.7.2.1 grading. After the endosperm particles are released from individual break-grinding passages, they are graded according to particle size in the correspondingsifter sections as already explained. There are several graded groups of material or stocks that are

from second break reachesthe third break-grinding passage where similar action is repeated and more endosperm isreleased and graded. The break stock that reaches the fourth and fth break, if the latter are used, would have very little endosperm remaining on the bran akes as most of it would already have been extracted and graded. Therefore, the purpose of the last break-grinding passage might be described as cleaning up the bran before it moves on to amachine commonly known as bran duster or nisher. This particular machine removesthe last traces of the endosperm that still adheres to the bran. There are two different sizesof bran that are produced. The coarse bran is referred to as bran, while the ne bran isreferred to as shorts. Both of these are passed through separate dusters: namely, bran duster and shorts duster. Thus, although very gradual breaking and releasing of the endosperm from wheat and subsequent break stocks is desired, at the same time millerhas to ensure that all the endosperm is released and the bran is cleaned up, using theavailable four or ve break passages and bran duster, before dispatching the bran to thebran bin. 2 Sarkar 3.3.7.2 Grading of the Released Endosperm and Purication 3.3.7.2.1 grading. After the endosperm particles are released from individual break-grinding passages, they are graded according to particle size in the correspondingsifter sections as already explained. There are several graded groups of material or stocks that are| Model Type | Bevel-helical gear boxes B3 |

|---|---|

| Gear Type | Bevel Helical Gear |

| Weight (kg) | 25700.000000 |

| Ratio Range | 1 : 22.4…80 |

| Low Speed Output | Flanged shaft |

| Nominal Torque | 1400000 Nm |

| Mounting Arrangements | Vertical mounting position |

| Manufacturer | Flender Corporation |

| Country of Manufacture | Haiti |

| Data Sheet & Drawings | quantity B V Dip lubri cationOil quantity B V B3-FV-28-D Bevel-helical gear boxes B3 |