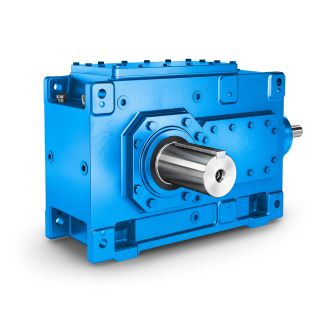

B3-FH-8-A ticle No LP Type Size d l G l l kg Solid Bevel-helical speed reducer B3

In stock

SKU

B3-FH-8-A

$17,142.86

Flender/Flender Gear Units/Bevel-helical speed reducer B3

s, and straw is the next important func- tion of thresher. The process begins as the grains, chaff, and straw rst leave the concaveopenings. During operation, large portion of threshed grain or seed along with some chaff and straw is

rst leave the concaveopenings. During operation, large portion of threshed grain or seed along with some chaff and straw is  separated from the straw by the threshing unit. Rotary separators and oscillatory straw carriers are the common forms of grain

separated from the straw by the threshing unit. Rotary separators and oscillatory straw carriers are the common forms of grain  separators adopted in all stationary 9 DattaTable 7 Range of CylinderConcave Parameters in Threshers for Cereal and Pulse Crops Peripheral

separators adopted in all stationary 9 DattaTable 7 Range of CylinderConcave Parameters in Threshers for Cereal and Pulse Crops Peripheral  Concave velocity Wrap angle clearance Crop (/) Cylinder conguration Concave conguration degree (mm) Ref. Paddy 2.0 Spike-tooth Rod and at-bar grating 2 6.0.0 4 1.7.0 Spike-tooth Rod and at-bar grating and louvers 1 1.0.0 6.6.4 Wire-loop Wire-loop 1 3.0.0 6 1.6.4 Rasp-bar Rasp-bar 1 3.0.0 6 2.0.0 Rasp-bar Rasp-bar 5.0.0 2 Wheat 1.5 Spike-tooth Rod and at-bar grating and louvers 1 9.0.0 6 1.0.4 Spike-tooth Rod and at-bar grating 1 1.0.0 6 2.0.0 Rasp-bar (double cylinder, Rod and at-bar grating 2 and 1.0.0 6 one above the other) 1 2.0.0 Rasp-bar Rasp-bar 5.0.0 2 Barley 2.5.5 Rasp-bar Rasp-bar 6.0.5 2Peas 1.0.0 Rasp-bar Rasp-bar 7.5.0 2 Pigeon pea 9.4.5 Spike-tooth Rod and at-bar grating and louvers 1 7.0.0 6 Chickpea 8.5.0 Spike-tooth Rod and at-bar grating and louvers 1 3.0.0 6 1.0.0 Rasp-bar Rod and square-bar grating 1 1.0.5 8.0.7 Spike-tooth Rod and at-bar grating and louvers 1 5.0.0 6 1.5.3 Plastic-covered peg-tooth Rod and square-bar grating 1 1.0.5 9 1.5.3 Plastic-covered 4 , wire-loop Rod and square-bar grating 1 1.0.0 9 Soybean 1.0.0 Rasp-bar Rod and square-bar grating 1 8.0.0 1 1.5.5 Rasp-bar Rasp-bar 7.5.0 2 1.0.0 Plastic-covered spike-tooth Rod and square-bar grating 1 1.0.0 1 5.5.5 Spike-tooth Angle-iron ribs parallel to cylinder 1 3.0 6 axis for upper concave (upper (upper concave) concave) Square-bar grating for lower concave 1 1.0 (lower (lower concave) concave) Harvesting and Threshing 9 threshers and combine harvesters. Primary separation of most grains

Concave velocity Wrap angle clearance Crop (/) Cylinder conguration Concave conguration degree (mm) Ref. Paddy 2.0 Spike-tooth Rod and at-bar grating 2 6.0.0 4 1.7.0 Spike-tooth Rod and at-bar grating and louvers 1 1.0.0 6.6.4 Wire-loop Wire-loop 1 3.0.0 6 1.6.4 Rasp-bar Rasp-bar 1 3.0.0 6 2.0.0 Rasp-bar Rasp-bar 5.0.0 2 Wheat 1.5 Spike-tooth Rod and at-bar grating and louvers 1 9.0.0 6 1.0.4 Spike-tooth Rod and at-bar grating 1 1.0.0 6 2.0.0 Rasp-bar (double cylinder, Rod and at-bar grating 2 and 1.0.0 6 one above the other) 1 2.0.0 Rasp-bar Rasp-bar 5.0.0 2 Barley 2.5.5 Rasp-bar Rasp-bar 6.0.5 2Peas 1.0.0 Rasp-bar Rasp-bar 7.5.0 2 Pigeon pea 9.4.5 Spike-tooth Rod and at-bar grating and louvers 1 7.0.0 6 Chickpea 8.5.0 Spike-tooth Rod and at-bar grating and louvers 1 3.0.0 6 1.0.0 Rasp-bar Rod and square-bar grating 1 1.0.5 8.0.7 Spike-tooth Rod and at-bar grating and louvers 1 5.0.0 6 1.5.3 Plastic-covered peg-tooth Rod and square-bar grating 1 1.0.5 9 1.5.3 Plastic-covered 4 , wire-loop Rod and square-bar grating 1 1.0.0 9 Soybean 1.0.0 Rasp-bar Rod and square-bar grating 1 8.0.0 1 1.5.5 Rasp-bar Rasp-bar 7.5.0 2 1.0.0 Plastic-covered spike-tooth Rod and square-bar grating 1 1.0.0 1 5.5.5 Spike-tooth Angle-iron ribs parallel to cylinder 1 3.0 6 axis for upper concave (upper (upper concave) concave) Square-bar grating for lower concave 1 1.0 (lower (lower concave) concave) Harvesting and Threshing 9 threshers and combine harvesters. Primary separation of most grains| Model Type | Bevel-helical speed reducer B3 |

|---|---|

| Gear Type | Bevel Helical Gear |

| Weight (kg) | 800.000000 |

| Ratio Range | 1 : 16…90 |

| Low Speed Output | Flanged shaft |

| Nominal Torque | 27200 Nm |

| Mounting Arrangements | Horizontal mounting position |

| Manufacturer | Flender Svenska AB |

| Country of Manufacture | Djibouti |

| Data Sheet & Drawings | B3-FH-8-A ticle No LP Type Size d l G l l kg Solid Bevel-helical speed reducer B3 |