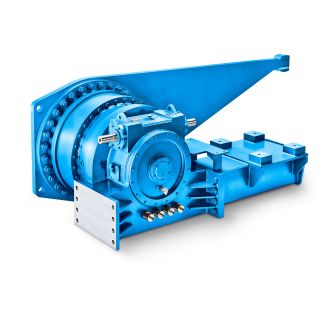

B3-FH-10-D unting position Type B Gear unit dimensions twost Bevel-helical gearbox B3

In stock

SKU

B3-FH-10-D

$19,928.57

Flender/Flender Gear Units/Bevel-helical gearbox B3

s. Inspection and overhaul uring the lifetime of your gearboxes, field inspections or overhauls are needed as indicated in the Gear Maintenance Manual. To increase the reliability and performance of your equipment we recommend using our Flender-Graffenstaden gear authorized field

Gear Maintenance Manual. To increase the reliability and performance of your equipment we recommend using our Flender-Graffenstaden gear authorized field  service specialists for the following activities: Complete disassembling inspection of the gearbox Visual check of each part Dimensional controls Clearance

service specialists for the following activities: Complete disassembling inspection of the gearbox Visual check of each part Dimensional controls Clearance  controls -assembling of the gearbox to Flender-Graffenstaden design standards Blue cont act tooth pattern check, documented and recorded for future

controls -assembling of the gearbox to Flender-Graffenstaden design standards Blue cont act tooth pattern check, documented and recorded for future  evaluation Replacement of spare parts Our field service team is able to install original spare parts and therefore warranty the proper functionning of your equipment to the original internal design specifications of Flender-Graffenstaden.Emergency service and repair With many years of experience, the Flender-Graffenstaden authorized field service team can provide the correct solution when emergency field services are needed. This emergency type repair is also fully directed and supported with the backup of all the different gear specialists located at the Flender-Graffenstaden headquarters. This will guarantee: High availability and reliability High operational safety Reactivity and flexibility Less stand still time echnical assistance The Flender-Graffenstaden field service team can be deputed to site and give you assistance on preventive maintenance, spare parts policy, inventory of spare parts, alignment verification, vibration and noise analysis, oil flow and efficiency documented by our trained specialists Field Service : we support your operations Consulting and Assistance : we deliver the highest quality We work closely with our customers throughout the entire life cycle of our product, starting from the offer to the after-sales service. so far as the manufacturer of High peed Gearing, we are the best ref erence concerning the

evaluation Replacement of spare parts Our field service team is able to install original spare parts and therefore warranty the proper functionning of your equipment to the original internal design specifications of Flender-Graffenstaden.Emergency service and repair With many years of experience, the Flender-Graffenstaden authorized field service team can provide the correct solution when emergency field services are needed. This emergency type repair is also fully directed and supported with the backup of all the different gear specialists located at the Flender-Graffenstaden headquarters. This will guarantee: High availability and reliability High operational safety Reactivity and flexibility Less stand still time echnical assistance The Flender-Graffenstaden field service team can be deputed to site and give you assistance on preventive maintenance, spare parts policy, inventory of spare parts, alignment verification, vibration and noise analysis, oil flow and efficiency documented by our trained specialists Field Service : we support your operations Consulting and Assistance : we deliver the highest quality We work closely with our customers throughout the entire life cycle of our product, starting from the offer to the after-sales service. so far as the manufacturer of High peed Gearing, we are the best ref erence concerning the| Model Type | Bevel-helical gearbox B3 |

|---|---|

| Gear Type | Bevel Helical Gear |

| Weight (kg) | 930.000000 |

| Ratio Range | 1 : 16…90 |

| Low Speed Output | Flanged shaft |

| Nominal Torque | 43800 Nm |

| Mounting Arrangements | Horizontal mounting position |

| Manufacturer | Flender Limited. |

| Country of Manufacture | France |

| Data Sheet & Drawings | B3-FH-10-D unting position Type B Gear unit dimensions twost Bevel-helical gearbox B3 |