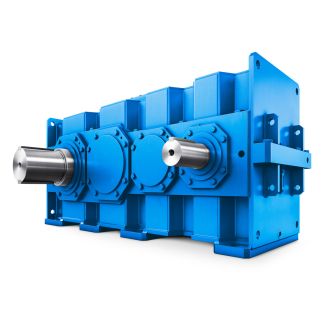

inforced bearing see page Flender GmbH Flend B3-DV5A Bevel-helical gear box B3

In stock

SKU

B3-DV5A

$18,750.00

Flender/Flender Gear Units/Bevel-helical gear box B3

reducing gear unit prevent, lubricant from the entering in the variable speed gear unit. In case of higher ambient temperatures (>4 ... 1 according to order agreement), shaft seal rings from temperature resistant material are used. 5.7 Cooling The gear

(>4 ... 1 according to order agreement), shaft seal rings from temperature resistant material are used. 5.7 Cooling The gear  units do not require any additional cooling. The generously dimensioned housing surface is sufficient for dissipating the heat loss in

units do not require any additional cooling. The generously dimensioned housing surface is sufficient for dissipating the heat loss in  case of free convection. The surface of the gear unit or the gear motor should be kept free of dirt

case of free convection. The surface of the gear unit or the gear motor should be kept free of dirt  (see Section 1. Maintenance and repair). 5.8 Couplings As rule, flexible couplings should be provided for the input drive and output drive sides of the gear unit. If rigid couplings or other input drive and output drive elements are used which give rise to additional radial and/or axial forces (for example gear wheels, belt pulleys, etc.), this must be agreed on by contract. Couplings with peripheral speeds at the outside diameter up to 3 / must be statically balanced. Couplings with peripheral speeds above 3 / require dynamic balancing. The special Operating Instructions should be noted for operation of the couplings.Attention! Attention! Attention! BA G2 EN 0.0 1 / 4.9 Backstop The gearboxes can be provided with mechanical backstop for certain requirements. During operation, this permits rotation in the specified direction only. This direction is marked by corresponding directionof rotation arrow. The backstop incorporates centrifugally operated grippers. When the gear unit is rotating in the specified direction, the inner ring and the cage with the grippers rotate, the outer ring remaining stationary. From certain speed of rotation, the grippers lift off and the back stop now operates without wear. The backstops are lubricated ready for duty, they dont need to be serviced. To prevent damage to or destruction of the backstop, it is essential to ensure that the motor is not run against the locked backstop. Please observe the notes on the gear. 5.1 Name plates The gear unit or g

(see Section 1. Maintenance and repair). 5.8 Couplings As rule, flexible couplings should be provided for the input drive and output drive sides of the gear unit. If rigid couplings or other input drive and output drive elements are used which give rise to additional radial and/or axial forces (for example gear wheels, belt pulleys, etc.), this must be agreed on by contract. Couplings with peripheral speeds at the outside diameter up to 3 / must be statically balanced. Couplings with peripheral speeds above 3 / require dynamic balancing. The special Operating Instructions should be noted for operation of the couplings.Attention! Attention! Attention! BA G2 EN 0.0 1 / 4.9 Backstop The gearboxes can be provided with mechanical backstop for certain requirements. During operation, this permits rotation in the specified direction only. This direction is marked by corresponding directionof rotation arrow. The backstop incorporates centrifugally operated grippers. When the gear unit is rotating in the specified direction, the inner ring and the cage with the grippers rotate, the outer ring remaining stationary. From certain speed of rotation, the grippers lift off and the back stop now operates without wear. The backstops are lubricated ready for duty, they dont need to be serviced. To prevent damage to or destruction of the backstop, it is essential to ensure that the motor is not run against the locked backstop. Please observe the notes on the gear. 5.1 Name plates The gear unit or g| Model Type | Bevel-helical gear box B3 |

|---|---|

| Gear Type | Bevel Helical Gear |

| Weight (kg) | 875.000000 |

| Ratio Range | 1 : 12.5…71 |

| Low Speed Output | Hollow shaft with shrink disk |

| Nominal Torque | 11600 Nm |

| Mounting Arrangements | Vertical mounting position |

| Manufacturer | Flender France S.A.R.L. |

| Country of Manufacture | El Salvador |

| Data Sheet & Drawings | inforced bearing see page Flender GmbH Flend B3-DV5A Bevel-helical gear box B3 |