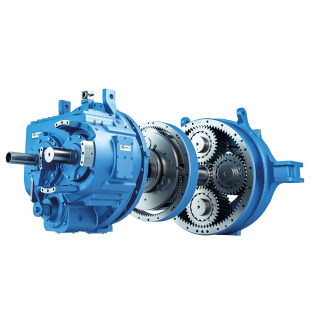

kn x st c Shaft seals see page onwards For de B3-DH5-B Bevel-helical gearbox B3

In stock

SKU

B3-DH5-B

$12,000.00

Flender/Flender Gear Units/Bevel-helical gearbox B3

raging provides the mean hardening distortion in the form of deviations. Onthe basis of these deviations, the machine and tool settings can be modied in such away that the bevel gear which theoretically results from the new settings exhibitsalmost the

settings can be modied in such away that the bevel gear which theoretically results from the new settings exhibitsalmost the  original desired geometry after hardening. Adaptation of the cutting tool may be necessary in order to compensate larger hardening distortions.

original desired geometry after hardening. Adaptation of the cutting tool may be necessary in order to compensate larger hardening distortions.  In milling process, such modication of the tool geometrycan take place only during the actual process development phase. In this

In milling process, such modication of the tool geometrycan take place only during the actual process development phase. In this  phase, hardening pre-correction is usually passed through only once. Slight re-corrections using modied machine settings then take place as needed in the running process.7.1 Measurement and Correction 3 7.1.5.4 Calculating Corrections Calculation of machine and hardening pre-corrections is very closely related to the calculation of ank modications, for example for the purpose of contact pattern development. The effects of additional machine motions on the tooth ank form (see Sect. 3.3.4 ) indicate the fundamental options for kinematic shaping of the ank form. The basic principle underlying all correction calculations is to compensate, with corrected machineand possibly toolsettings, the deviations from the nominal data which result from manufacture. The necessary corrections must be determined in such way that they will approximate the geometry as closely as possible to reference geometry obtained by mirroring the measured deviations on the desired theoretical geometry. For tooth ank topography, for example, mirroring can take place point wise along the respective tooth ank normal vectors, transferring each measured deviation in the opposite direction along the normal vectors. The same procedure can be followed for tooth depth. For tooth thickness, the tooth thickness angle error is mirrored. Solving the inverse problem, that is to determine the corrected machine and tool settings for prescribed reference geometry, .. the systematic calculation o

phase, hardening pre-correction is usually passed through only once. Slight re-corrections using modied machine settings then take place as needed in the running process.7.1 Measurement and Correction 3 7.1.5.4 Calculating Corrections Calculation of machine and hardening pre-corrections is very closely related to the calculation of ank modications, for example for the purpose of contact pattern development. The effects of additional machine motions on the tooth ank form (see Sect. 3.3.4 ) indicate the fundamental options for kinematic shaping of the ank form. The basic principle underlying all correction calculations is to compensate, with corrected machineand possibly toolsettings, the deviations from the nominal data which result from manufacture. The necessary corrections must be determined in such way that they will approximate the geometry as closely as possible to reference geometry obtained by mirroring the measured deviations on the desired theoretical geometry. For tooth ank topography, for example, mirroring can take place point wise along the respective tooth ank normal vectors, transferring each measured deviation in the opposite direction along the normal vectors. The same procedure can be followed for tooth depth. For tooth thickness, the tooth thickness angle error is mirrored. Solving the inverse problem, that is to determine the corrected machine and tool settings for prescribed reference geometry, .. the systematic calculation o| Model Type | Bevel-helical gearbox B3 |

|---|---|

| Gear Type | Bevel Helical Gear |

| Weight (kg) | 560.000000 |

| Ratio Range | 1 : 12.5…71 |

| Low Speed Output | Hollow shaft with shrink disk |

| Nominal Torque | 11600 Nm |

| Mounting Arrangements | Horizontal mounting position |

| Manufacturer | A. FRIEDR. FLENDER AG |

| Country of Manufacture | Germany |

| Data Sheet & Drawings | kn x st c Shaft seals see page onwards For de B3-DH5-B Bevel-helical gearbox B3 |