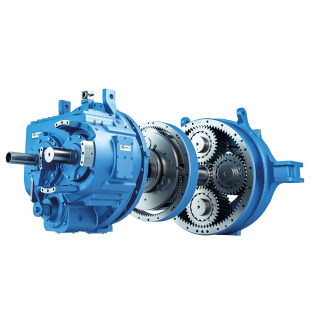

ata acc to orderrelated documentation Without oi B3-DH6A Bevel-helical speed reducer B3

In stock

SKU

B3-DH6A

$10,778.57

Flender/Flender Gear Units/Bevel-helical speed reducer B3

ral oil (CLP oil DIN 5/- synthetic oil with specific base (PGLP-) Specifications like oil type, oil viscosity and required oil quantity are shown on the name plate (see 3.. Oil change and oil flushing: If using the same type

oil quantity are shown on the name plate (see 3.. Oil change and oil flushing: If using the same type  of oil as before, use only that oil. If using new oil type, use only the new type. Thoroughly remove

of oil as before, use only that oil. If using new oil type, use only the new type. Thoroughly remove  oil sludge, abraded material and used oil residue from the housings by oil flushing. Note: High-viscosity oils must be warmed

oil sludge, abraded material and used oil residue from the housings by oil flushing. Note: High-viscosity oils must be warmed  beforehand. The oil should be drained off after shutdown, while the gear unit is still warm. Shut down the gear unit by shutting off the drive unit. Secure drive unit to prevent accidental startup. Affix notice at the switch-on point. Place suitable collection receptacle under the oil drain plug of the gear unit housing. Unscrew ventilator filter on the upper side of the housing. Unscrew oil drain plug and drain oil off into the receptacle. There is risk of scalding from the hot oil emerging. Wear protective gloves. Screw in oil drain plug. Note: Check condition of seal ring, use new seal ring if necessary. Filling with lubricant see 7.1.4. Screw in ventilator filter on the upper side of the housing. 1.2.2 Relubricating the anti-friction bearings in drive units Relubricating the drive units is necessary from motor size 2 on. The lubricating period of one year or 4 operating hours refers to temperature of 5 measured on the housing surface near the bearing point. Note: In case of temperatures exceeding 5 , the lubricating period should be reduced by half of the original value for each temperature increase of 1 . Do not mix greases of different soap bases when relubricating. The grease is injected into the bearing point by means of grease gun via the grease nipples provided for this purpose. See 1.3 for lubricating greases to be used. Note: Inject 5 grease per lubricating point, unless other specifications are given in the vicinity of the lubricating point.Attention! Attention! Attention! BA G2 EN 0.0 3 / 4.2

beforehand. The oil should be drained off after shutdown, while the gear unit is still warm. Shut down the gear unit by shutting off the drive unit. Secure drive unit to prevent accidental startup. Affix notice at the switch-on point. Place suitable collection receptacle under the oil drain plug of the gear unit housing. Unscrew ventilator filter on the upper side of the housing. Unscrew oil drain plug and drain oil off into the receptacle. There is risk of scalding from the hot oil emerging. Wear protective gloves. Screw in oil drain plug. Note: Check condition of seal ring, use new seal ring if necessary. Filling with lubricant see 7.1.4. Screw in ventilator filter on the upper side of the housing. 1.2.2 Relubricating the anti-friction bearings in drive units Relubricating the drive units is necessary from motor size 2 on. The lubricating period of one year or 4 operating hours refers to temperature of 5 measured on the housing surface near the bearing point. Note: In case of temperatures exceeding 5 , the lubricating period should be reduced by half of the original value for each temperature increase of 1 . Do not mix greases of different soap bases when relubricating. The grease is injected into the bearing point by means of grease gun via the grease nipples provided for this purpose. See 1.3 for lubricating greases to be used. Note: Inject 5 grease per lubricating point, unless other specifications are given in the vicinity of the lubricating point.Attention! Attention! Attention! BA G2 EN 0.0 3 / 4.2| Model Type | Bevel-helical speed reducer B3 |

|---|---|

| Gear Type | Bevel Helical Gear |

| Weight (kg) | 503.000000 |

| Ratio Range | 1 : 16…90 |

| Low Speed Output | Hollow shaft with shrink disk |

| Nominal Torque | 15500 Nm |

| Mounting Arrangements | Horizontal mounting position |

| Manufacturer | Flender Ges.m.b.H. |

| Country of Manufacture | Paraguay |

| Data Sheet & Drawings | ata acc to orderrelated documentation Without oi B3-DH6A Bevel-helical speed reducer B3 |