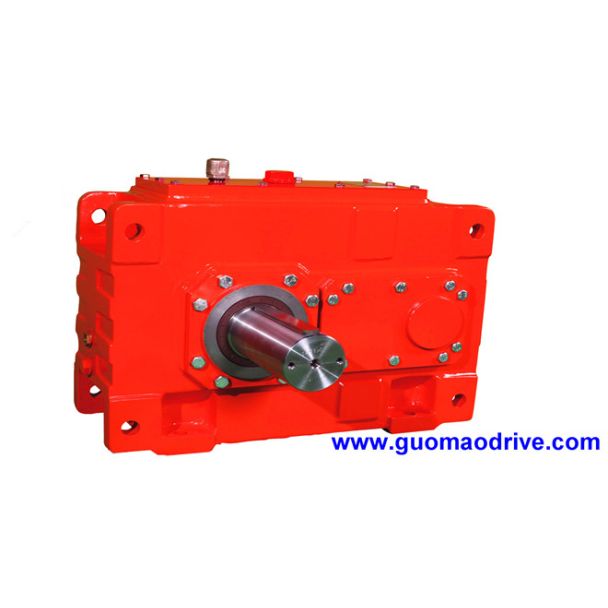

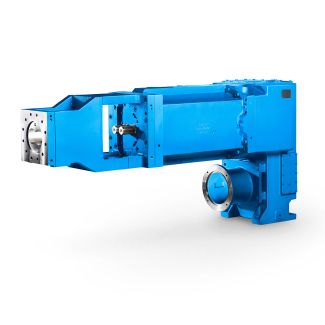

n Without oil filling Shaft version with reinfor B3-DH-12B Bevel-helical gearbox B3

In stock

SKU

B3-DH-12B

$40,714.29

Flender/Flender Gear Units/Bevel-helical gearbox B3

rator with permanent magnets only has to supply relatively low fre- quency(3 Hz)toseparatealuminium. If non-ferrousmetalsareto beseparated,themagnet- ic alternating field requires frequencies of over 6 Hz. Over 9/0 of the aluminium can be separated from real material mixtures, such as represented

frequencies of over 6 Hz. Over 9/0 of the aluminium can be separated from real material mixtures, such as represented  by shredder scrap. The content in the recyclate then likewise exceeds 9%. Reliable separation of the metahon-metal mixtures is ossible

by shredder scrap. The content in the recyclate then likewise exceeds 9%. Reliable separation of the metahon-metal mixtures is ossible  down to particle size of 3 ".The prerequisiteforthis isthatthe prepared materiaiscleanand ideallyfed intothesepa- rating chamber in single-particle layer, so that

down to particle size of 3 ".The prerequisiteforthis isthatthe prepared materiaiscleanand ideallyfed intothesepa- rating chamber in single-particle layer, so that  the metals to be ejected do notentrain the resi- dual material. Several high-performance units have been in use for some time in appropriate sorting plants. Due to the use of permanent magnets, operation of the eddy current separators requires very little energy, this making them inexpensive to run. ~ ~ ~ __ ~ . 2 Duration: 0.0.8 - 3 . 0.8 0 ZH8 Subject: Development of new process for processing waste oil by means of single-tube reactor Research centre: SUDOL MineraloCRaffinerie GmbH Postfach 1 5, 7 Eislingen Government sponsorship: DM 1,2,1.0 Sponsorship ratio: 5% 1. Purpose of the project prox 5,0 tpa waste oil used to arise in the old Federal Republic. 3,0 tonnes there- ofwere reprocessed in 1. The reprocessing method used to date both in Germany and worldwide is based on acid treatment and clay treatment. The products obtained are equival- ent to primary raffinates. However, the process has the disadvantage of low oil yield and, above all, 3 hazardous waste which is difficult to dispose of results from every 1 dry waste oil. num%er of other treatment and reprocessing methodsforwasteoil are known, but these are either not essential different from our process, or cannot be used due to technical and economic reasons and, tKerefore, have not been used economically anywhere to date. Messrs. ENTRA have developed method for reprocessing liquid

the metals to be ejected do notentrain the resi- dual material. Several high-performance units have been in use for some time in appropriate sorting plants. Due to the use of permanent magnets, operation of the eddy current separators requires very little energy, this making them inexpensive to run. ~ ~ ~ __ ~ . 2 Duration: 0.0.8 - 3 . 0.8 0 ZH8 Subject: Development of new process for processing waste oil by means of single-tube reactor Research centre: SUDOL MineraloCRaffinerie GmbH Postfach 1 5, 7 Eislingen Government sponsorship: DM 1,2,1.0 Sponsorship ratio: 5% 1. Purpose of the project prox 5,0 tpa waste oil used to arise in the old Federal Republic. 3,0 tonnes there- ofwere reprocessed in 1. The reprocessing method used to date both in Germany and worldwide is based on acid treatment and clay treatment. The products obtained are equival- ent to primary raffinates. However, the process has the disadvantage of low oil yield and, above all, 3 hazardous waste which is difficult to dispose of results from every 1 dry waste oil. num%er of other treatment and reprocessing methodsforwasteoil are known, but these are either not essential different from our process, or cannot be used due to technical and economic reasons and, tKerefore, have not been used economically anywhere to date. Messrs. ENTRA have developed method for reprocessing liquid| Model Type | Bevel-helical gearbox B3 |

|---|---|

| Gear Type | Bevel Helical Gear |

| Weight (kg) | 1900.000000 |

| Ratio Range | 1 : 16…90 |

| Low Speed Output | Hollow shaft with shrink disk |

| Nominal Torque | 77200 Nm |

| Mounting Arrangements | Horizontal mounting position |

| Manufacturer | Flender..Ltd China(Tianjin) |

| Country of Manufacture | Sweden |

| Data Sheet & Drawings | n Without oil filling Shaft version with reinfor B3-DH-12B Bevel-helical gearbox B3 |