B3-CV-5-A forces including those caused by weight of gear un Bevel-helical gear reducers B3

In stock

SKU

B3-CV-5-A

$12,000.00

Flender/Flender Gear Units/Bevel-helical gear reducers B3

partial list of which is given in Table 1. Thechoice of system is therefore function of the range and type of products to be stored ina given facility, the volume handled, and number of other factors that will be explained

of products to be stored ina given facility, the volume handled, and number of other factors that will be explained  in the major sections of this chapter: precooling, cooling and refrigeration, and modica- tion of atmospheric composition. 1.1 Background 1.1.1

in the major sections of this chapter: precooling, cooling and refrigeration, and modica- tion of atmospheric composition. 1.1 Background 1.1.1  Temperature Temperature is the single most important factor affecting the deterioration rate of harvested commodities (. The rate of deterioration

Temperature Temperature is the single most important factor affecting the deterioration rate of harvested commodities (. The rate of deterioration  is proportional to the respiration rate of thecommodity, which is temperature-dependent. For each 1 reduction in temperature, the respiration rate of wide range of produce can be reduced by factor of 2 to 4 (. Moreover, the activity of postharvest pathogens and insects is also suppressed by lowtemperatures (. Therefore, cooling and refrigeration are important to preserving the qual- ity of fresh fruits and vegetables and to extending their storage lives. The ideal storage temperature varies from product to product, and the temperature maintained in the storage area should be within 1 ( 2F) of that level (. Lower tempera- tures may cause chilling injury and higher ones can reduce the storage life of the product.If the temperature is allowed to uctuate beyond the desired range, the produce may expe-rience increased water loss and condensation may develop on the product from the sur-rounding air (, leading to the growth of microorganisms. Temperature uctuations can be prevented by using the proper equipment to refrigerate the storage room. The refrigeration unit must be able to handle the maximal refrigeration load that is expected. If the load is too great for the refrigeration unit, then the temperature rises. Therefrigeration system should also be designed such that the air leaving the coils is as closeto the desired room temperature as possible. This limits the frequency at which the systemturns on and off. Use of coils with large surface area

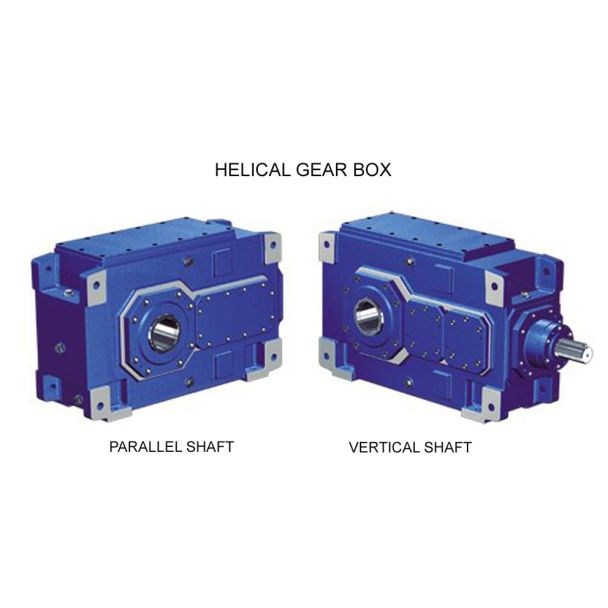

is proportional to the respiration rate of thecommodity, which is temperature-dependent. For each 1 reduction in temperature, the respiration rate of wide range of produce can be reduced by factor of 2 to 4 (. Moreover, the activity of postharvest pathogens and insects is also suppressed by lowtemperatures (. Therefore, cooling and refrigeration are important to preserving the qual- ity of fresh fruits and vegetables and to extending their storage lives. The ideal storage temperature varies from product to product, and the temperature maintained in the storage area should be within 1 ( 2F) of that level (. Lower tempera- tures may cause chilling injury and higher ones can reduce the storage life of the product.If the temperature is allowed to uctuate beyond the desired range, the produce may expe-rience increased water loss and condensation may develop on the product from the sur-rounding air (, leading to the growth of microorganisms. Temperature uctuations can be prevented by using the proper equipment to refrigerate the storage room. The refrigeration unit must be able to handle the maximal refrigeration load that is expected. If the load is too great for the refrigeration unit, then the temperature rises. Therefrigeration system should also be designed such that the air leaving the coils is as closeto the desired room temperature as possible. This limits the frequency at which the systemturns on and off. Use of coils with large surface area| Model Type | Bevel-helical gear reducers B3 |

|---|---|

| Gear Type | Bevel Helical Gear |

| Weight (kg) | 560.000000 |

| Ratio Range | 1 : 12.5…71 |

| Low Speed Output | Solid shaft without parallel key |

| Nominal Torque | 11600 Nm |

| Mounting Arrangements | Vertical mounting position |

| Manufacturer | Flender Svenska AB |

| Country of Manufacture | San Marino |

| Data Sheet & Drawings | B3-CV-5-A forces including those caused by weight of gear un Bevel-helical gear reducers B3 |