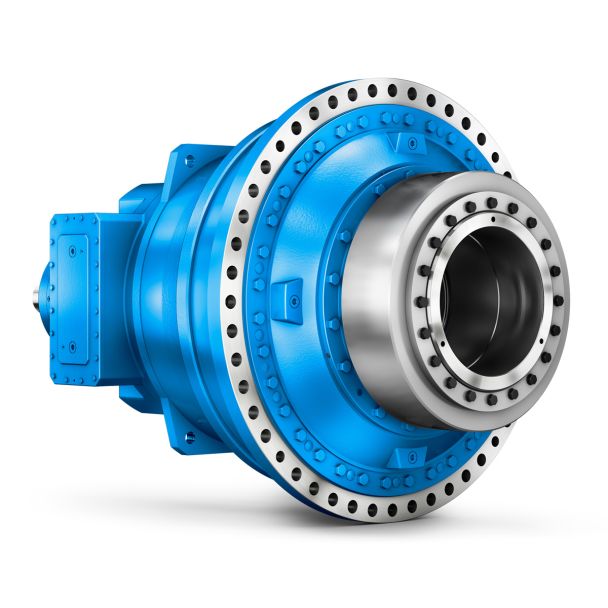

B3-CH21-B page onwards Approximate values exact data acc Bevel-helical gear Reduction Boxes B3

In stock

SKU

B3-CH21-B

$197,142.86

Flender/Flender Gear Units/Bevel-helical gear Reduction Boxes B3

ower the belt Mining | MineralsFocus 2/2 Author: Felipe Contreras Fuentes, contreras.felipe Siemens Flender siemens HB series gearbox MineralsFocus 2/2 | Mining 2The worlds second conveyor belt system equipped with gearless drives is located at the Antapaccay mine in Peru

| Mining 2The worlds second conveyor belt system equipped with gearless drives is located at the Antapaccay mine in Peru  Gearless drives Belts rolling at Antapaccay Mining | MineralsFocus 2/2 Gearless drives Belts rolling at Antapaccay 2MineralsFocus 2/2 | Mining

Gearless drives Belts rolling at Antapaccay Mining | MineralsFocus 2/2 Gearless drives Belts rolling at Antapaccay 2MineralsFocus 2/2 | Mining  Siemens has commissioned the worlds second gearless conveyor system in the Antapaccay copper mine in Peru. This is the first

Siemens has commissioned the worlds second gearless conveyor system in the Antapaccay copper mine in Peru. This is the first  time this technology has been imple-mented on large scale outside Germany. The belt conveyor transports ore from the mine to the processing plant at speed of 6.2 / The Siemens Drive Technologies Division has commissioned gearless belt conveyor system in the Antapaccay copper mine in Peru. This is the first large-scale ref-erence for this technology outside Germany. The mine, 4,2 above sea level, belongs to Xstrata Copper and is scheduled to produce an aver - age of 1,0 tons of copper in concentrate per annum in the initial years of its more than 2-year pro-jected mine life. The gearless drives will help to boost the efficiency and reliability of the conveyor system in Peru and reduce maintenance requirements when compared with conventional systems. In addition, the Siemens scope of supply in- cludes the entire switchgears and gearless drive systems for 4-ft SAG mill and two 2-ft ball mills with the associated power supply. Efficient, reliable and safe The belt system in the Antapaccay copper mine was supplied by Thyssen-Krupp and transports ore from the mine to the processing plant over distance of around 6.5 km. With belt width of 1,3 mm and con-veyor speed of 6.2 /, approxi- mately 5,2 tons of ore can be transported in an hour. The con-veyor system is the second of its 2kind worldwide. The first belt system with gearless drives was installed back in 1 by Siemens and ThyssenKrupp (previously &) in the Prosper-Han-

time this technology has been imple-mented on large scale outside Germany. The belt conveyor transports ore from the mine to the processing plant at speed of 6.2 / The Siemens Drive Technologies Division has commissioned gearless belt conveyor system in the Antapaccay copper mine in Peru. This is the first large-scale ref-erence for this technology outside Germany. The mine, 4,2 above sea level, belongs to Xstrata Copper and is scheduled to produce an aver - age of 1,0 tons of copper in concentrate per annum in the initial years of its more than 2-year pro-jected mine life. The gearless drives will help to boost the efficiency and reliability of the conveyor system in Peru and reduce maintenance requirements when compared with conventional systems. In addition, the Siemens scope of supply in- cludes the entire switchgears and gearless drive systems for 4-ft SAG mill and two 2-ft ball mills with the associated power supply. Efficient, reliable and safe The belt system in the Antapaccay copper mine was supplied by Thyssen-Krupp and transports ore from the mine to the processing plant over distance of around 6.5 km. With belt width of 1,3 mm and con-veyor speed of 6.2 /, approxi- mately 5,2 tons of ore can be transported in an hour. The con-veyor system is the second of its 2kind worldwide. The first belt system with gearless drives was installed back in 1 by Siemens and ThyssenKrupp (previously &) in the Prosper-Han-| Model Type | Bevel-helical gear Reduction Boxes B3 |

|---|---|

| Gear Type | Bevel Helical Gear |

| Weight (kg) | 9200.000000 |

| Ratio Range | 1 : 12.5…71 |

| Low Speed Output | Solid shaft without parallel key |

| Nominal Torque | 420000 Nm |

| Mounting Arrangements | Horizontal mounting position |

| Manufacturer | Flender de Mexico, S.A. de C.V. |

| Country of Manufacture | Malaysia |

| Data Sheet & Drawings | B3-CH21-B page onwards Approximate values exact data acc Bevel-helical gear Reduction Boxes B3 |