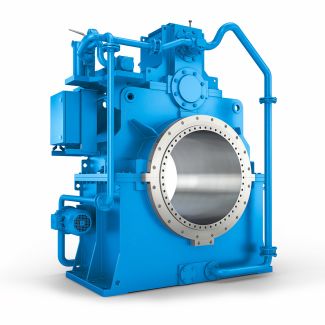

Bevel-helical gear Reduction Box B2 inertia J in kgm relative to the low speed shaft B2HV-5-C

In stock

SKU

B2HV-5-C

$254,571.43

Flender/Flender Gear Units/Bevel-helical gear Reduction Box B2

mum of space, short rinsin times, and ?te smallest volume of water possible.All types of electroplated articles (smooth.%ulky, hollow) were considered in this context. Further- more, the study also had to investigate how foreign substances accumulate in the process baths

considered in this context. Further- more, the study also had to investigate how foreign substances accumulate in the process baths  when the entrained solution is completely recycled, what effect they have on the surface treatment, and which material-specific regeneration measures

when the entrained solution is completely recycled, what effect they have on the surface treatment, and which material-specific regeneration measures  must be carried out in orderto remove these foreign substances from the process baths. Re eneration also helps to increase

must be carried out in orderto remove these foreign substances from the process baths. Re eneration also helps to increase  the service life of the baths.These studies were initially carriec?out on laboratory scale and the results then scaled up to industrial dimensions. 6 - -__ ______ - - ___-- Todealwiththesmallvolumeof unavoidablewastewater,multistepdetoxification, neutralisa- tion, urificationand postpurification procedures were to be developedand technicallytested, whicR enable residual metal concentrations in the ppb range to be reached through synergistic effects, despite the neutral salt and complexing agent content of the waste water 3. Results The studies carried out led to the following results: 1. The dramatic reduction in the consumption of rinsing water proved feasible in continuous operation. In comparison with conventional rinsing technique, the water consumption, and thus the quantity of waste water, amounts to only 4.5%. 2. two-step waste water purification procedure involving replenishment with organic sulphides enables the heavy metal concentrations to be reduced by roughly 7/ to 3/1 compared to one-step neutralisation precipitation. The prerequisite is that the production chemicals must be coordinated with the precipitation process used. 3. As result of these measures, the heav metal load was reduced to 1.4%. The oal of the project of attaining heavy metal load oronly 1 OIo was not completely reached,al$ough the results in the rinsin technology sector exceeded expectations. The reduction of the metal c

the service life of the baths.These studies were initially carriec?out on laboratory scale and the results then scaled up to industrial dimensions. 6 - -__ ______ - - ___-- Todealwiththesmallvolumeof unavoidablewastewater,multistepdetoxification, neutralisa- tion, urificationand postpurification procedures were to be developedand technicallytested, whicR enable residual metal concentrations in the ppb range to be reached through synergistic effects, despite the neutral salt and complexing agent content of the waste water 3. Results The studies carried out led to the following results: 1. The dramatic reduction in the consumption of rinsing water proved feasible in continuous operation. In comparison with conventional rinsing technique, the water consumption, and thus the quantity of waste water, amounts to only 4.5%. 2. two-step waste water purification procedure involving replenishment with organic sulphides enables the heavy metal concentrations to be reduced by roughly 7/ to 3/1 compared to one-step neutralisation precipitation. The prerequisite is that the production chemicals must be coordinated with the precipitation process used. 3. As result of these measures, the heav metal load was reduced to 1.4%. The oal of the project of attaining heavy metal load oronly 1 OIo was not completely reached,al$ough the results in the rinsin technology sector exceeded expectations. The reduction of the metal c| Model Type | Bevel-helical gear Reduction Box B2 |

|---|---|

| Gear Type | Bevel Helical Gear |

| Weight (kg) | 11880.000000 |

| Ratio Range | 1 : 5…18 |

| Low Speed Output | Hollow shaft with keyway acc. to DIN 6885/1 |

| Nominal Torque | 9400 Nm |

| Mounting Arrangements | Vertical mounting position |

| Manufacturer | Flender Himmel RSA |

| Country of Manufacture | Azerbaijan |

| Data Sheet & Drawings | Bevel-helical gear Reduction Box B2 inertia J in kgm relative to the low speed shaft B2HV-5-C |