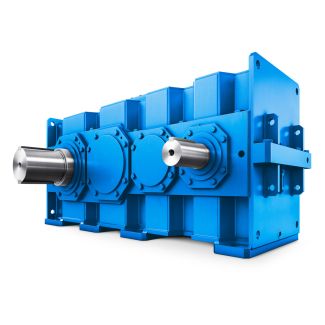

der for the right solution because in many cases B2-SV-10-D Bevel-helical gear reducer B2

In stock

SKU

B2-SV-10-D

$379,285.71

Flender/Flender Gear Units/Bevel-helical gear reducer B2

lion and thus for 4% of the tdtal funds granted The funds for developing new sector-specific environmental technologies were primarily expended on the manufacturing industries, whose 4 segments shared no less than 7% of the total sponsorship volume In this

expended on the manufacturing industries, whose 4 segments shared no less than 7% of the total sponsorship volume In this  context, 4% of all sponsorship funds went to segments which are of particular relevance as regards emissions, - Pulp industry,

context, 4% of all sponsorship funds went to segments which are of particular relevance as regards emissions, - Pulp industry,  - Chemical industry, - Non-ferrous metal industry, - Pit and quarry industry, - Textile industry Thesolidwastesectorheadedthelistwhen it cametothedistribution ofthes onsorshipfunds

- Chemical industry, - Non-ferrous metal industry, - Pit and quarry industry, - Textile industry Thesolidwastesectorheadedthelistwhen it cametothedistribution ofthes onsorshipfunds  among the individual environmentalsectors Rouqhly DM 2 3 million, and tEusalmost half of the sponsorship funds, were spent on process &el'opments in this sector. The other environ- mental sectors received substantially less promotion. Projects in the exhaust air sector had the hi hest average sponsorship volume of DM 1.2 million, closely followed by projects in the soyid waste area with DM 1.2 million. By the end of 1,2 sponsored ap lication-oriented research projects with total spon- sorshipvolume of DM 2.1 million hatbeen successfully completed. Given an averages on sorship ratio pf 5%, the BMFTand the recipients of the grants together invested sum orDM 4 6 million in these projects. In this context, the BMFT initially displayed preference for end-of-pipe technolo ies Howev- er, there was subsequently lasting shift in the sponsorship focus, towards the Ievelopment of integrated measures, with the result that these ultimately predominated. While only DM 8.6 million in onsorship funds went into the development of separation and disposal pro- cesses, total oPDM 1 3.5 million was spent on the development of utilisation and avoidance processes. The indicators of the success of the completed plication-oriented research projects-in the field of environmental technology, and thus of tge success of research promotion, are the implementation rate and the economic and ecological effective

among the individual environmentalsectors Rouqhly DM 2 3 million, and tEusalmost half of the sponsorship funds, were spent on process &el'opments in this sector. The other environ- mental sectors received substantially less promotion. Projects in the exhaust air sector had the hi hest average sponsorship volume of DM 1.2 million, closely followed by projects in the soyid waste area with DM 1.2 million. By the end of 1,2 sponsored ap lication-oriented research projects with total spon- sorshipvolume of DM 2.1 million hatbeen successfully completed. Given an averages on sorship ratio pf 5%, the BMFTand the recipients of the grants together invested sum orDM 4 6 million in these projects. In this context, the BMFT initially displayed preference for end-of-pipe technolo ies Howev- er, there was subsequently lasting shift in the sponsorship focus, towards the Ievelopment of integrated measures, with the result that these ultimately predominated. While only DM 8.6 million in onsorship funds went into the development of separation and disposal pro- cesses, total oPDM 1 3.5 million was spent on the development of utilisation and avoidance processes. The indicators of the success of the completed plication-oriented research projects-in the field of environmental technology, and thus of tge success of research promotion, are the implementation rate and the economic and ecological effective| Model Type | Bevel-helical gear reducer B2 |

|---|---|

| Gear Type | Bevel Helical Gear |

| Weight (kg) | 17700.000000 |

| Ratio Range | 1 : 6.3…22.4 |

| Low Speed Output | Solid shaft with parallel key acc. to DIN 6885/1 |

| Nominal Torque | 38000 Nm |

| Mounting Arrangements | Vertical mounting position |

| Manufacturer | Flender de Mexico, S.A. de C.V. |

| Country of Manufacture | Algeria |

| Data Sheet & Drawings | der for the right solution because in many cases B2-SV-10-D Bevel-helical gear reducer B2 |