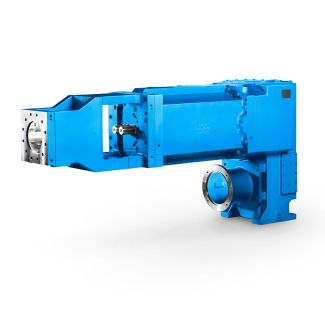

B2-SH-8-A e mills Shears Continuous cut Crank type Bevel-helical gear box B2

In stock

SKU

B2-SH-8-A

$18,750.00

Flender/Flender Gear Units/Bevel-helical gear box B2

le for this purpose, in which an even dispersion of nutrients and microorganisms, as well as standardisation, can most readily be ensured The test duration is from 2 to 6 days, depending on the degradation behaviour and the test system

be ensured The test duration is from 2 to 6 days, depending on the degradation behaviour and the test system  employed Monitoring of degradation via the BOD in an aerobic environment Monitoring of degradation via the COz release in an

employed Monitoring of degradation via the BOD in an aerobic environment Monitoring of degradation via the COz release in an  aerobic environment Monitoring of degradation via the production of biogas (methane and CO?) in an anaerobic . environment 2.2 Simulation

aerobic environment Monitoring of degradation via the production of biogas (methane and CO?) in an anaerobic . environment 2.2 Simulation  of waste disposal conditions Trials under realisticconditionswere carried out atthe same time in order to be ableto investi- gate the relevance and/or transferability of short-time test in an aqueous environment. Household landfill and composting facilities are of primary interest as regards the disposal of waste. Composting on laboratory scale Landfill simulation 2.3 Simulation of environmentally relevant conditions Soil burial Aquariums for simulating surface water 1 ,-_____I 3. Results 3.1 Screening tests The biodegradability of films and powdery materials can be monitored via the BOD and the evolution of C0 in an aerobic environment and via the biogas release in an anaerobicenviron- ment. In the case of materials which comprise more than one component, the summary para- meter BOD or C0 alone is not sufficient as the sole assessment variable to establish the com- plete degradation of the material; an approximate balance should also be drawn up. Non- automated systems, such as the Sturm Test, are only suitable for short trial periods. Materials which require an incubation time longer than 3 to maximum of 6 days should be investi- gated in automated systems (BSB-Digi, Denimat, Methanomat: Buhler, Bodelshausen) or by simulation. The screening methods in the aerobic and anaerobic aqueous environment were tested and largely optimised as regards the media, inocula and analytical methods employed. 3.2 Realistic trials 3.2.1 Compost simulation

of waste disposal conditions Trials under realisticconditionswere carried out atthe same time in order to be ableto investi- gate the relevance and/or transferability of short-time test in an aqueous environment. Household landfill and composting facilities are of primary interest as regards the disposal of waste. Composting on laboratory scale Landfill simulation 2.3 Simulation of environmentally relevant conditions Soil burial Aquariums for simulating surface water 1 ,-_____I 3. Results 3.1 Screening tests The biodegradability of films and powdery materials can be monitored via the BOD and the evolution of C0 in an aerobic environment and via the biogas release in an anaerobicenviron- ment. In the case of materials which comprise more than one component, the summary para- meter BOD or C0 alone is not sufficient as the sole assessment variable to establish the com- plete degradation of the material; an approximate balance should also be drawn up. Non- automated systems, such as the Sturm Test, are only suitable for short trial periods. Materials which require an incubation time longer than 3 to maximum of 6 days should be investi- gated in automated systems (BSB-Digi, Denimat, Methanomat: Buhler, Bodelshausen) or by simulation. The screening methods in the aerobic and anaerobic aqueous environment were tested and largely optimised as regards the media, inocula and analytical methods employed. 3.2 Realistic trials 3.2.1 Compost simulation| Model Type | Bevel-helical gear box B2 |

|---|---|

| Gear Type | Bevel Helical Gear |

| Weight (kg) | 875.000000 |

| Ratio Range | 1 : 6.3…22.4 |

| Low Speed Output | Solid shaft with parallel key acc. to DIN 6885/1 |

| Nominal Torque | 23800 Nm |

| Mounting Arrangements | Horizontal mounting position |

| Manufacturer | Flender Guss Gmbh & Co. Kg |

| Country of Manufacture | Mongolia |

| Data Sheet & Drawings | B2-SH-8-A e mills Shears Continuous cut Crank type Bevel-helical gear box B2 |