B2-SH-12-A ants mechanical refrigerators juice boilers S Bevel-helical speed reducer B2

In stock

SKU

B2-SH-12-A

$49,178.57

Flender/Flender Gear Units/Bevel-helical speed reducer B2

lectr icity consumption and peak demand Equipment run times including downtimes for repairs and maintenance Equipment design specifications Instrumentation and plant control Electricity consumption rates and costs for major equipment Part of data collection should include site walk thro ugh

plant control Electricity consumption rates and costs for major equipment Part of data collection should include site walk thro ugh  survey to fill in the gaps in the data that is available in records and document. The survey should include:

survey to fill in the gaps in the data that is available in records and document. The survey should include:  Verification of equipment data and operating status Physical measurement of energy use and efficiency of large equipment .. large pumps

Verification of equipment data and operating status Physical measurement of energy use and efficiency of large equipment .. large pumps  and aeration equipment (blowers and surface aerators) Interview Operations staff to: obtain data that is recorded on site and not necessarily passed onto head office Understand & practices and priorities Understand any limitations (regulatory, engineering, personnel) to implementing ECMs Collect suggestions for energy conservation opportunities Identify any Operator Initiative energy conservation measures that are in place Identify where additional metering is requ ired in order to obtain more information on energy use. Identify sampling points for collection of additional wastewater data Verify PFDs and &IDS Analyse Data and Determine Baseline Plant Performance The above data should be analysed to establish th influent flows, loads as well as baseline plant performance in terms of compliance with final effluent regulations. Theoretical baseline aeration energy requirements should also be de termined using process models. The following analysis is recommended us ing data from site measurements: Calculate Influent loads including seasonal and di urnal trends and variations as well as process control parameters Analyse aeration and control strategies Compare final effluent quality with final effluent discharge standards Apply mathematical modelling and simulation to determine aeration energy requirements, optimal process and aeration control parameters as well as model predict

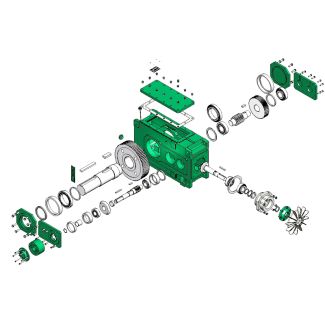

and aeration equipment (blowers and surface aerators) Interview Operations staff to: obtain data that is recorded on site and not necessarily passed onto head office Understand & practices and priorities Understand any limitations (regulatory, engineering, personnel) to implementing ECMs Collect suggestions for energy conservation opportunities Identify any Operator Initiative energy conservation measures that are in place Identify where additional metering is requ ired in order to obtain more information on energy use. Identify sampling points for collection of additional wastewater data Verify PFDs and &IDS Analyse Data and Determine Baseline Plant Performance The above data should be analysed to establish th influent flows, loads as well as baseline plant performance in terms of compliance with final effluent regulations. Theoretical baseline aeration energy requirements should also be de termined using process models. The following analysis is recommended us ing data from site measurements: Calculate Influent loads including seasonal and di urnal trends and variations as well as process control parameters Analyse aeration and control strategies Compare final effluent quality with final effluent discharge standards Apply mathematical modelling and simulation to determine aeration energy requirements, optimal process and aeration control parameters as well as model predict| Model Type | Bevel-helical speed reducer B2 |

|---|---|

| Gear Type | Bevel Helical Gear |

| Weight (kg) | 2295.000000 |

| Ratio Range | 1 : 6.3…22.4 |

| Low Speed Output | Solid shaft with parallel key acc. to DIN 6885/1 |

| Nominal Torque | 66300 Nm |

| Mounting Arrangements | Horizontal mounting position |

| Manufacturer | Flender France S.A.R.L. |

| Country of Manufacture | Panama |

| Data Sheet & Drawings | B2-SH-12-A ants mechanical refrigerators juice boilers S Bevel-helical speed reducer B2 |