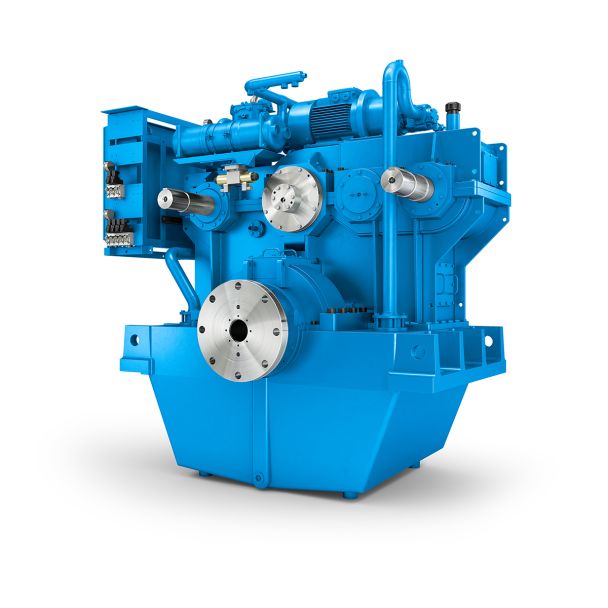

B2-SH-12-D t Centrifugal compressors Cable railways Mater Bevel-helical gear units B2

In stock

SKU

B2-SH-12-D

$49,178.57

Flender/Flender Gear Units/Bevel-helical gear units B2

lectrocoat tank or by the paint solid, - minimization of the contacting surface of the coated products before and during the baking Also for bulk goods-coating the phosphatization can be replaced by especially adapted chro- matization with success The obtained

the baking Also for bulk goods-coating the phosphatization can be replaced by especially adapted chro- matization with success The obtained  results show economical and ecological advantages which give the processvery good marketing chances The economical aspect of the simplified coating

results show economical and ecological advantages which give the processvery good marketing chances The economical aspect of the simplified coating  compared with conventional technique as well as the totally new coating process for bulkgoods allow to expect demant of industrial

compared with conventional technique as well as the totally new coating process for bulkgoods allow to expect demant of industrial  appliers by KTL-coating process, 7 Duration: 0 0 8 - 3 0 8 0 VQ2 Subject: Development of processes and equi ment for manufacturing integrated printed conductors gy hot-stamping special copper foils on all types of thermoplastic Research centre: Ivo lrion & Vosseler Zahlerfabrik GmbH & Co Dauchinger Strasse 5 - 6,7 Villingen-Schwenningen Government sponsorship: DM 7,9 0 Sponsorship ratio: 5 / 1. Purpose of the project In orderto avoid electroplating processes in the manufacture of printed circuit boards (PCBs), rocesswasto be developed toapply anytypeof printed conductorto suitablesubstrates, pre- Perably thermoplastics, using the hot-stamping method These printed conductors were to be hot-stam ed onto flat substrates corres onding to common PCBs, as well as onto suitable, not necessariL flat surfaces of all ty es of knctional elements in electrical or electronic devices Processing times in the region orseveral seconds can be expected forthis hot-stamping proc- ess The process has since been patented in Europeand the USA Additional applications have been submitted in the leading industrral nations 2. Working steps The bases of the development were devised in cooperation with the Fraunhofer-Gesellschaft (IGB and IPA). The project plan can be divided into three areas: Part 1 Start-up of semi-industrial test installation for the electroplating of copper foil with the required low ductility Testing and fu

appliers by KTL-coating process, 7 Duration: 0 0 8 - 3 0 8 0 VQ2 Subject: Development of processes and equi ment for manufacturing integrated printed conductors gy hot-stamping special copper foils on all types of thermoplastic Research centre: Ivo lrion & Vosseler Zahlerfabrik GmbH & Co Dauchinger Strasse 5 - 6,7 Villingen-Schwenningen Government sponsorship: DM 7,9 0 Sponsorship ratio: 5 / 1. Purpose of the project In orderto avoid electroplating processes in the manufacture of printed circuit boards (PCBs), rocesswasto be developed toapply anytypeof printed conductorto suitablesubstrates, pre- Perably thermoplastics, using the hot-stamping method These printed conductors were to be hot-stam ed onto flat substrates corres onding to common PCBs, as well as onto suitable, not necessariL flat surfaces of all ty es of knctional elements in electrical or electronic devices Processing times in the region orseveral seconds can be expected forthis hot-stamping proc- ess The process has since been patented in Europeand the USA Additional applications have been submitted in the leading industrral nations 2. Working steps The bases of the development were devised in cooperation with the Fraunhofer-Gesellschaft (IGB and IPA). The project plan can be divided into three areas: Part 1 Start-up of semi-industrial test installation for the electroplating of copper foil with the required low ductility Testing and fu| Model Type | Bevel-helical gear units B2 |

|---|---|

| Gear Type | Bevel Helical Gear |

| Weight (kg) | 2295.000000 |

| Ratio Range | 1 : 6.3…22.4 |

| Low Speed Output | Solid shaft with parallel key acc. to DIN 6885/1 |

| Nominal Torque | 66300 Nm |

| Mounting Arrangements | Horizontal mounting position |

| Manufacturer | Flender ATB-Loher |

| Country of Manufacture | Peru |

| Data Sheet & Drawings | B2-SH-12-D t Centrifugal compressors Cable railways Mater Bevel-helical gear units B2 |