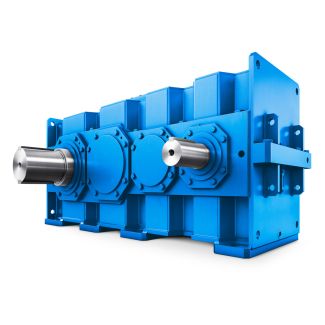

Bevel-helical speed reduction gearboxes B2 es for flanged shaft gear units on request Mass m B2-HH15A

In stock

SKU

B2-HH15A

$107,785.71

Flender/Flender Gear Units/Bevel-helical speed reduction gearboxes B2

mperature, pressure and electric power) are of high quality (= and it is important to validate the signal quality with regular intervals. Besides the 1-minutes statistics, also entire time series with wind and structural load measurements are uploaded to DTU

regular intervals. Besides the 1-minutes statistics, also entire time series with wind and structural load measurements are uploaded to DTU  every night - each time series contains 1 MB of 3 Hz data. Representative series are selected and inserted into

every night - each time series contains 1 MB of 3 Hz data. Representative series are selected and inserted into  WindData speed reducers, where they have been indexed and made searchable for the student exercises. Furthermore tools have been developed

WindData speed reducers, where they have been indexed and made searchable for the student exercises. Furthermore tools have been developed  to organize the time series in database, which enables online plots and analysis with Matlab. WIND TURBINE EVENTS number of special wind turbine events have been logged and identified during the recent 2 years. One major event has been short-circuit failure on the generator when operating at rated power (5 kW). The accident required repair of the generator before restart of the wind turbine. The event - see Figure 8 below - demonstrates how an emergency stop sequence activates both tip brakes and the mechanical brake and how the wind turbine handles rotor over-speed situation. Furthermore, the gearbox is heavily loaded due to the reversing torque in the main shaft during the stop sequence. 5 5 5 5 5 5Nordtank - 1/2-2 2:0WS3 - / 5 5 5 5 5 5-1-5Power - kW 5 5 5 5 5 5-2Torque - kNm 5 5 5 5 5 5Generator speed - rpm 5 5 5 5 5 5rotor position - deg Seconds Figure 8: Example of recorded emergency stop. CONCLUSION An on-line wind turbine laboratory has been established in joint project between DTU and Ris National Laboratory. The measurement laboratory is installed on 5 kW Nordtank wind turbine that runs in daily operation. Presented at EWEC 2, Athens 2 February 2 March 2 Page 8/8 The wind turbine has been fully equipped with sensors and an Internet accessible data acquisition system has been set-up. The on-line laboratory has been in operation for more than two years. The main purpose is to give the students hands-on insight in methods f

to organize the time series in database, which enables online plots and analysis with Matlab. WIND TURBINE EVENTS number of special wind turbine events have been logged and identified during the recent 2 years. One major event has been short-circuit failure on the generator when operating at rated power (5 kW). The accident required repair of the generator before restart of the wind turbine. The event - see Figure 8 below - demonstrates how an emergency stop sequence activates both tip brakes and the mechanical brake and how the wind turbine handles rotor over-speed situation. Furthermore, the gearbox is heavily loaded due to the reversing torque in the main shaft during the stop sequence. 5 5 5 5 5 5Nordtank - 1/2-2 2:0WS3 - / 5 5 5 5 5 5-1-5Power - kW 5 5 5 5 5 5-2Torque - kNm 5 5 5 5 5 5Generator speed - rpm 5 5 5 5 5 5rotor position - deg Seconds Figure 8: Example of recorded emergency stop. CONCLUSION An on-line wind turbine laboratory has been established in joint project between DTU and Ris National Laboratory. The measurement laboratory is installed on 5 kW Nordtank wind turbine that runs in daily operation. Presented at EWEC 2, Athens 2 February 2 March 2 Page 8/8 The wind turbine has been fully equipped with sensors and an Internet accessible data acquisition system has been set-up. The on-line laboratory has been in operation for more than two years. The main purpose is to give the students hands-on insight in methods f| Model Type | Bevel-helical speed reduction gearboxes B2 |

|---|---|

| Gear Type | Bevel Helical Gear |

| Weight (kg) | 5030.000000 |

| Ratio Range | 1 : 5…18 |

| Low Speed Output | Hollow shaft with keyway acc. to DIN 6885/1 |

| Nominal Torque | 132000 Nm |

| Mounting Arrangements | Horizontal mounting position |

| Manufacturer | Flender Brasil Ltda |

| Country of Manufacture | United States |

| Data Sheet & Drawings | Bevel-helical speed reduction gearboxes B2 es for flanged shaft gear units on request Mass m B2-HH15A |