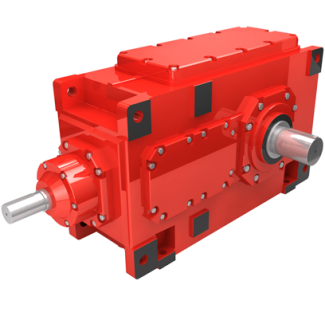

Bevel-helical gearboxes B2 h H s c E an e m m nA Al G G l B Gl m Bb GMDEN Ai B2-FV14A

In stock

SKU

B2-FV14A

$21,857.14

Flender/Flender Gear Units/Bevel-helical gearboxes B2

ntenance and servicing activities Further information Further information about additional maintenance and servicing activities can be found in the separate data sheet in the overall documentation for the gear unit. Further information about installed components can be found in the

data sheet in the overall documentation for the gear unit. Further information about installed components can be found in the  operating instructions for the components in the complete documentation for the gear unit. 8.3 Maintenance and servicing work 8.3 Maintenance

operating instructions for the components in the complete documentation for the gear unit. 8.3 Maintenance and servicing work 8.3 Maintenance  and servicing work Introduction You can find maintenance and servicing measures relating to gear unit lubrication and pre- servation, which

and servicing work Introduction You can find maintenance and servicing measures relating to gear unit lubrication and pre- servation, which  are not provided in this chapter, in instructions7 in the complete docu- mentation for the gear unit. 8.3.1 Checking the oil temperature 8.3 Maintenance and servicing work Damage to the gear unit due to excessively high oil sump temperatures. The gear unit can sustain damage due to inadequate lubrication if you allow it to operate at oil sump temperatures above the maximum permissible temperature. Do not operate the gear unit above the maximum permissible oil sump temperature. Procedure Proceed as follows to check the oil temperature: 1.Allow the gear unit to reach its normal operating temperature. 2.Operate the gear unit with the maximum driven machine power. 3.Measure the temperature of the oil in the oil sump. 4 HB series gearbox pare the measured value with the maximum permissible oil temperature ( Page . 5.Immediately stop the gear unit if the maximum permissible oil temperature is exceeded. Contact Flender Customer Services. Servicing 8.3 Maintenance and servicing work 7 Edition 0/2 B5-0 en8.3.2 Filling the backstop with oil 8.3 Maintenance and servicing work Oil type and filling filter When filling the backstop with oil, observe the following points: Use the same oil type and oil viscosity as for the gear unit itself. Use filling filter with the same filter mesh size as for the gear unit itself. Procedure Proceed as follows to fill the backstop with oil: 1.Clean the oil filling point of the backstop. 2.Open the oil f

are not provided in this chapter, in instructions7 in the complete docu- mentation for the gear unit. 8.3.1 Checking the oil temperature 8.3 Maintenance and servicing work Damage to the gear unit due to excessively high oil sump temperatures. The gear unit can sustain damage due to inadequate lubrication if you allow it to operate at oil sump temperatures above the maximum permissible temperature. Do not operate the gear unit above the maximum permissible oil sump temperature. Procedure Proceed as follows to check the oil temperature: 1.Allow the gear unit to reach its normal operating temperature. 2.Operate the gear unit with the maximum driven machine power. 3.Measure the temperature of the oil in the oil sump. 4 HB series gearbox pare the measured value with the maximum permissible oil temperature ( Page . 5.Immediately stop the gear unit if the maximum permissible oil temperature is exceeded. Contact Flender Customer Services. Servicing 8.3 Maintenance and servicing work 7 Edition 0/2 B5-0 en8.3.2 Filling the backstop with oil 8.3 Maintenance and servicing work Oil type and filling filter When filling the backstop with oil, observe the following points: Use the same oil type and oil viscosity as for the gear unit itself. Use filling filter with the same filter mesh size as for the gear unit itself. Procedure Proceed as follows to fill the backstop with oil: 1.Clean the oil filling point of the backstop. 2.Open the oil f| Model Type | Bevel-helical gearboxes B2 |

|---|---|

| Gear Type | Bevel Helical Gear |

| Weight (kg) | 1020.000000 |

| Ratio Range | 1 : 6.3…22.4 |

| Low Speed Output | Flanged shaft |

| Nominal Torque | 101000 Nm |

| Mounting Arrangements | Vertical mounting position |

| Manufacturer | F. H. Transmissiones S.A |

| Country of Manufacture | Jordan |

| Data Sheet & Drawings | Bevel-helical gearboxes B2 h H s c E an e m m nA Al G G l B Gl m Bb GMDEN Ai B2-FV14A |