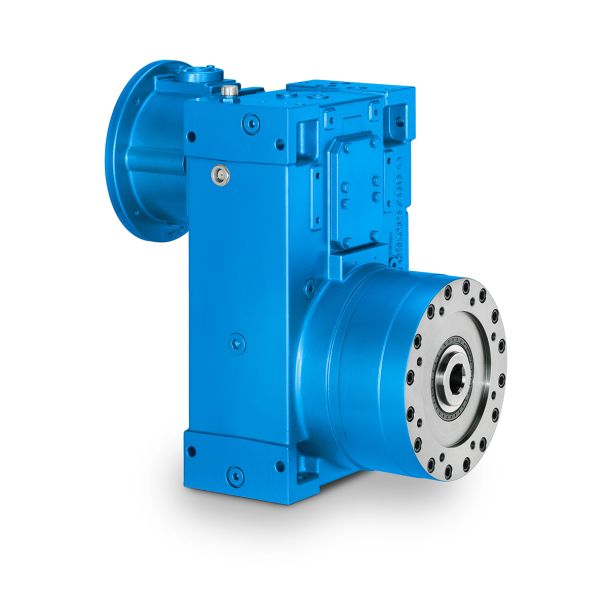

Bevel-helical speed reduction gearbox B2 ment for th to th position see pages to Ar B2-FV-9-D

In stock

SKU

B2-FV-9-D

$6,857.14

Flender/Flender Gear Units/Bevel-helical speed reduction gearbox B2

nt teas are usually produced from low-cost raw materials. Indian instant teas with superior avor are generally used for upgrading the instant teas produced in Europe (1, . 3.5 Tea Concentrates Tea leaves are extracted with hot water at 8

the instant teas produced in Europe (1, . 3.5 Tea Concentrates Tea leaves are extracted with hot water at 8  C9C. secondary extraction ensures complete recovery of soluble solids, using water at 9 C1C. Additives such as citric acid and

C9C. secondary extraction ensures complete recovery of soluble solids, using water at 9 C1C. Additives such as citric acid and  sodium bicarbonate facilitate better extraction. The extract is claried and concen- trated by using either evaporation or the freeze-concentration method.

sodium bicarbonate facilitate better extraction. The extract is claried and concen- trated by using either evaporation or the freeze-concentration method.  To the concentratedbrew, sugar, stabilizers (xanthan, CMC, or carrageen), emulsiers (mono- and diglycer-ides, lecithin, or ethoxy fatty alcohols), preservatives (sodium benzoate, potassium sor-bate), and avorings (lemon oil or orange oil) are added. The product is storable (6 ) 7 Nagalakshmi for 6 months without deterioration and is used for the preparation of liquid teabased beverages (. 3.6 Tea Beverages 3.6.1 Ready-to-Serve Beverages Fresh tea brew (brown tea) is consumed hot over most of the world; in India and Britain it is consumed with milk and sugar. Nowadays ready-to-serve (RTS) products based ontea, .., Teh Botole and related products, popular in Indonesia, represent signicantshare of the soft drink market. This is noncarbonated bottled tea beverage prepared from Teh Wangi, processed green tea with jasmine avor. Clarity of the beverage and its shelf life are well maintained. Tea beverages in various forms that can be stored for long periods are common (. Vinication of tea extracts is possible. Claried and unclaried aqueous tea extract is fermented by Saccharomyces cerevisiae var.Montachet and by . bayanus , after sweet- ening with sugar to 2 Brix. Theaavin, caffeine, and theobromine levels in the fermenting process must decrease progressively over period of 1 weeks. The soluble amino acidsare reduced by more than 9% by . bayanus in 1 week in the presence of added ammo- nium phosphate. Thearubigins remain unchanged. Marked astringency d

To the concentratedbrew, sugar, stabilizers (xanthan, CMC, or carrageen), emulsiers (mono- and diglycer-ides, lecithin, or ethoxy fatty alcohols), preservatives (sodium benzoate, potassium sor-bate), and avorings (lemon oil or orange oil) are added. The product is storable (6 ) 7 Nagalakshmi for 6 months without deterioration and is used for the preparation of liquid teabased beverages (. 3.6 Tea Beverages 3.6.1 Ready-to-Serve Beverages Fresh tea brew (brown tea) is consumed hot over most of the world; in India and Britain it is consumed with milk and sugar. Nowadays ready-to-serve (RTS) products based ontea, .., Teh Botole and related products, popular in Indonesia, represent signicantshare of the soft drink market. This is noncarbonated bottled tea beverage prepared from Teh Wangi, processed green tea with jasmine avor. Clarity of the beverage and its shelf life are well maintained. Tea beverages in various forms that can be stored for long periods are common (. Vinication of tea extracts is possible. Claried and unclaried aqueous tea extract is fermented by Saccharomyces cerevisiae var.Montachet and by . bayanus , after sweet- ening with sugar to 2 Brix. Theaavin, caffeine, and theobromine levels in the fermenting process must decrease progressively over period of 1 weeks. The soluble amino acidsare reduced by more than 9% by . bayanus in 1 week in the presence of added ammo- nium phosphate. Thearubigins remain unchanged. Marked astringency d| Model Type | Bevel-helical speed reduction gearbox B2 |

|---|---|

| Gear Type | Bevel Helical Gear |

| Weight (kg) | 320.000000 |

| Ratio Range | 1 : 5…18 |

| Low Speed Output | Flanged shaft |

| Nominal Torque | 29900 Nm |

| Mounting Arrangements | Vertical mounting position |

| Manufacturer | Siemens Flender |

| Country of Manufacture | Germany |

| Data Sheet & Drawings | Bevel-helical speed reduction gearbox B2 ment for th to th position see pages to Ar B2-FV-9-D |