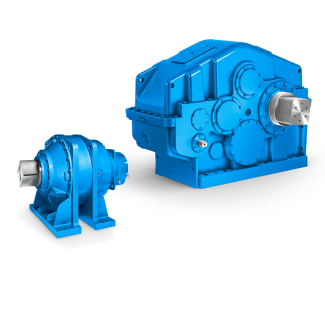

covers from size GMDENsD dd c bmm m m nn eE a B2-DH16-B Bevel-helical speed reducers B2

In stock

SKU

B2-DH16-B

$6,857.14

Flender/Flender Gear Units/Bevel-helical speed reducers B2

nadium-bearing slag without the use of ammonium salts Research centre: Werk Nurnberg der GFE Hofener Str 4,9 Nurnberg Government sponsorship: DM 2,0,7 1 Sponsorship ratio: 3 YO 1. Purpose of the project In the rocesses known to date for extracting

DM 2,0,7 1 Sponsorship ratio: 3 YO 1. Purpose of the project In the rocesses known to date for extracting  vanadium from vanadium-bearing raw materials (slag torn the steel industry, old catalytic coherters, oil-burning residues and flue ash), the vanadium

vanadium from vanadium-bearing raw materials (slag torn the steel industry, old catalytic coherters, oil-burning residues and flue ash), the vanadium  is precipitated from the concentrated lyes using ammonium salts which, in terms of ammonia, ;tail considerable waste water burden The

is precipitated from the concentrated lyes using ammonium salts which, in terms of ammonia, ;tail considerable waste water burden The  aim of this project is to develop new process which works entirely without ammonium salts in the precipitation stage In this way, pollution of the waste water by NH3 in industrial vanadium oxide extraction is to be eliminated 2. Working steps The concept of the roject is to roduce concentrated lye free of NH3 from the vanadium- bearing product of tRe sodium-akaline roasting processand to precipitate sodium vanadate via adjustment of the test arameters to be investigated This precipitate must be examined as regards its suitability for tEe subsequent stages leading up to ferro-vanadium (process tech- nology, quality, reaction conditions) The work programme initially envisages laboratory trials to clarify the following points - Development of precipitation process byvar ing the parameters, temperature, pH value, - Optimisation of the laboratory precipitation conditions - Investigation of the filtration, washing and drying properties of the precipitate - Conditioning of the precipitate, adaptation to existing technology in units used for further After conclusion of thelaboratorytrials,thereareplanstoscaleuptheoptimum resultstgsemi- industrial dimensions in order to check the laboratory results To this end, pilot plant is to be constructed on the basis of the knowledge gained in the laboratory Finally, planttrial isenvis- aged to determine the design data for the precipitation stage Aquantitycorresponding to curre

aim of this project is to develop new process which works entirely without ammonium salts in the precipitation stage In this way, pollution of the waste water by NH3 in industrial vanadium oxide extraction is to be eliminated 2. Working steps The concept of the roject is to roduce concentrated lye free of NH3 from the vanadium- bearing product of tRe sodium-akaline roasting processand to precipitate sodium vanadate via adjustment of the test arameters to be investigated This precipitate must be examined as regards its suitability for tEe subsequent stages leading up to ferro-vanadium (process tech- nology, quality, reaction conditions) The work programme initially envisages laboratory trials to clarify the following points - Development of precipitation process byvar ing the parameters, temperature, pH value, - Optimisation of the laboratory precipitation conditions - Investigation of the filtration, washing and drying properties of the precipitate - Conditioning of the precipitate, adaptation to existing technology in units used for further After conclusion of thelaboratorytrials,thereareplanstoscaleuptheoptimum resultstgsemi- industrial dimensions in order to check the laboratory results To this end, pilot plant is to be constructed on the basis of the knowledge gained in the laboratory Finally, planttrial isenvis- aged to determine the design data for the precipitation stage Aquantitycorresponding to curre| Model Type | Bevel-helical speed reducers B2 |

|---|---|

| Gear Type | Bevel Helical Gear |

| Weight (kg) | 320.000000 |

| Ratio Range | 1 : 5.6…20 |

| Low Speed Output | Hollow shaft with shrink disk |

| Nominal Torque | 148000 Nm |

| Mounting Arrangements | Horizontal mounting position |

| Manufacturer | Siemens AG |

| Country of Manufacture | Paraguay |

| Data Sheet & Drawings | covers from size GMDENsD dd c bmm m m nn eE a B2-DH16-B Bevel-helical speed reducers B2 |