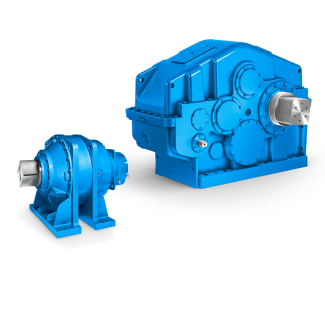

h fan LP Remove air guide cover before B2-DH-16-D Bevel-helical gear Reduction Boxes B2

In stock

SKU

B2-DH-16-D

$6,857.14

Flender/Flender Gear Units/Bevel-helical gear Reduction Boxes B2

nal combination of the two. During the off-crop, with zero grinding rate, thi three backpressure machines, the "Turbo Sueco", and the "Turbo Aleman" will generate an average of 2 MW. Of this, 3 MW will be required by the factory

the "Turbo Aleman" will generate an average of 2 MW. Of this, 3 MW will be required by the factory  and 5 MW by the field, leaving 1 MW to be sold to INE. The fuel needed to satisfy the

and 5 MW by the field, leaving 1 MW to be sold to INE. The fuel needed to satisfy the  field and factory demands for electrical energy, and for having 1 MW available for sale, amounts to 7 of ,6

field and factory demands for electrical energy, and for having 1 MW available for sale, amounts to 7 of ,6  wood chips or 2 (6,0 gal) of fuel oil per day, or any proportional combination of the two. . Results and Future Perspectives 1. Technical and Financial Results The technical and financial results of the current operations at Victoria de Julio are outlined in Chapters VII and VIII. 2. Future Perspectives In view of the information obtained at Victoria de Julio and presented in this report, it is reasonable to expect, in the short and medium term, the following variations or changes in the cost-determining parameters: Yearly cane supply will continue to increase, in spite of setbacks, due to the possibility of complementary sources of cane, like the area South of the Tipitapa River. 0 Crop and off-crop personnel will decline to around 4 and 2 persons respectively within the next two years. Even if an average grinding rate of 4,5 per day is assumed, man-days per ton of sugar are above 1.1 at the present level of staffing. 2% reduction would leave crop personnel at 4 and, by symmetry, off-crop per sonnel at 2. This would mean 0.9 man-days per ton of sugar, which is entirely justifiable with factory of this size and level of technology. The need to purchase electric power from INE during the crop will decrease as the power generating and distribution part of the original project is completed. Scenarios should be specified, taking account of the revenue potential of power sold commercially. * The number of periods will vary as function of both cane available and grinding rate per day. The range of variation wi

wood chips or 2 (6,0 gal) of fuel oil per day, or any proportional combination of the two. . Results and Future Perspectives 1. Technical and Financial Results The technical and financial results of the current operations at Victoria de Julio are outlined in Chapters VII and VIII. 2. Future Perspectives In view of the information obtained at Victoria de Julio and presented in this report, it is reasonable to expect, in the short and medium term, the following variations or changes in the cost-determining parameters: Yearly cane supply will continue to increase, in spite of setbacks, due to the possibility of complementary sources of cane, like the area South of the Tipitapa River. 0 Crop and off-crop personnel will decline to around 4 and 2 persons respectively within the next two years. Even if an average grinding rate of 4,5 per day is assumed, man-days per ton of sugar are above 1.1 at the present level of staffing. 2% reduction would leave crop personnel at 4 and, by symmetry, off-crop per sonnel at 2. This would mean 0.9 man-days per ton of sugar, which is entirely justifiable with factory of this size and level of technology. The need to purchase electric power from INE during the crop will decrease as the power generating and distribution part of the original project is completed. Scenarios should be specified, taking account of the revenue potential of power sold commercially. * The number of periods will vary as function of both cane available and grinding rate per day. The range of variation wi| Model Type | Bevel-helical gear Reduction Boxes B2 |

|---|---|

| Gear Type | Bevel Helical Gear |

| Weight (kg) | 320.000000 |

| Ratio Range | 1 : 5.6…20 |

| Low Speed Output | Hollow shaft with shrink disk |

| Nominal Torque | 148000 Nm |

| Mounting Arrangements | Horizontal mounting position |

| Manufacturer | A. FRIEDR. FLENDER AG |

| Country of Manufacture | Philippines |

| Data Sheet & Drawings | h fan LP Remove air guide cover before B2-DH-16-D Bevel-helical gear Reduction Boxes B2 |