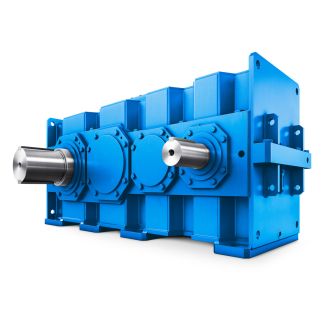

B2-DH11A e H Gear unit dimensions singlestage gear unit s Bevel-helical speed reducer B2

In stock

SKU

B2-DH11A

$173,571.43

Flender/Flender Gear Units/Bevel-helical speed reducer B2

n using the CFG calculating program and the actual operating data is recommended. When the gear units are well utilized (as rule, in the range between 6 and 8% of the nominal output torque), the permitted load data lies above

(as rule, in the range between 6 and 8% of the nominal output torque), the permitted load data lies above  the values specified in the tables.Symbols on the gear unit and in the dimensional drawing The following symbols, some of

the values specified in the tables.Symbols on the gear unit and in the dimensional drawing The following symbols, some of  which are color-highlighted, are provided for the gear unit: Earth connection point Air relief point Yellow Oil filling point Yellow

which are color-highlighted, are provided for the gear unit: Earth connection point Air relief point Yellow Oil filling point Yellow  Oil draining point White Oil level indicator Red Oil level measurement Red Vibration monitoring connection point Lubrication point Red Apply grease Lifting eye Eyebolt Do not unscrew Alignment surface, horizontal Alignment surface, vertical Flender GmbH 2NER GROUP CO.,LIMITED Germany sogears HB series gearbox 2/1 Flender MD 2.1 2Introduction Notes Flender GmbH 2NER GROUP CO.,LIMITED Germany sogears HB series gearbox Flender MD 2.1 2 3/2 Determining the drive data Checklist Guidelines for selection 3/3 Constant mechanical power rating 3/5 Variable power rating 3/6 Selection aid for low speed shaft (LSS) 3/7 Explanation of designations 3/8 Calculation example 3/1 Service factors 3/1 Designs for crane applications Overview tables 3/1 Type H1 3/2 Type H2 3/2 Type H3 3/3 Type H4 3/4 Type B2 3/4 Type B3 3/6 Type B4 3/6 Types H1, H2, H3, H4 Mass moments of inertia J1 3/7 Types B2, B3, B4 Mass moments of inertia J1 3/7 Types H1, H2, H3, H4 Actual ratios 3/7 Types B2, B3, B4 Actual ratios Design of the gear units Flender GmbH 2NER GROUP CO.,LIMITED Germany sogears HB series gearbox 3/2 Flender MD 2.1 2Design of the gear units Standardized helical and bevel helical gear units Determining the drive data Checklist GeneralBasic version and load data Gear unit type: Helical gear units Bevel helical gear units Right-angle gear units Gear units with auxiliary drive Quantity: Unit Torque at low speed shaft (LSS): Nm Max. peak torque: Nm Motor power: kW Permissible ratio: % Motor speed: rpm Required bearing lifetime L1 mh : Hours Power at

Oil draining point White Oil level indicator Red Oil level measurement Red Vibration monitoring connection point Lubrication point Red Apply grease Lifting eye Eyebolt Do not unscrew Alignment surface, horizontal Alignment surface, vertical Flender GmbH 2NER GROUP CO.,LIMITED Germany sogears HB series gearbox 2/1 Flender MD 2.1 2Introduction Notes Flender GmbH 2NER GROUP CO.,LIMITED Germany sogears HB series gearbox Flender MD 2.1 2 3/2 Determining the drive data Checklist Guidelines for selection 3/3 Constant mechanical power rating 3/5 Variable power rating 3/6 Selection aid for low speed shaft (LSS) 3/7 Explanation of designations 3/8 Calculation example 3/1 Service factors 3/1 Designs for crane applications Overview tables 3/1 Type H1 3/2 Type H2 3/2 Type H3 3/3 Type H4 3/4 Type B2 3/4 Type B3 3/6 Type B4 3/6 Types H1, H2, H3, H4 Mass moments of inertia J1 3/7 Types B2, B3, B4 Mass moments of inertia J1 3/7 Types H1, H2, H3, H4 Actual ratios 3/7 Types B2, B3, B4 Actual ratios Design of the gear units Flender GmbH 2NER GROUP CO.,LIMITED Germany sogears HB series gearbox 3/2 Flender MD 2.1 2Design of the gear units Standardized helical and bevel helical gear units Determining the drive data Checklist GeneralBasic version and load data Gear unit type: Helical gear units Bevel helical gear units Right-angle gear units Gear units with auxiliary drive Quantity: Unit Torque at low speed shaft (LSS): Nm Max. peak torque: Nm Motor power: kW Permissible ratio: % Motor speed: rpm Required bearing lifetime L1 mh : Hours Power at| Model Type | Bevel-helical speed reducer B2 |

|---|---|

| Gear Type | Bevel Helical Gear |

| Weight (kg) | 8100.000000 |

| Ratio Range | 1 : 5…18 |

| Low Speed Output | Hollow shaft with shrink disk |

| Nominal Torque | 54000 Nm |

| Mounting Arrangements | Horizontal mounting position |

| Manufacturer | A. Fried. Flender AG |

| Country of Manufacture | China |

| Data Sheet & Drawings | B2-DH11A e H Gear unit dimensions singlestage gear unit s Bevel-helical speed reducer B2 |