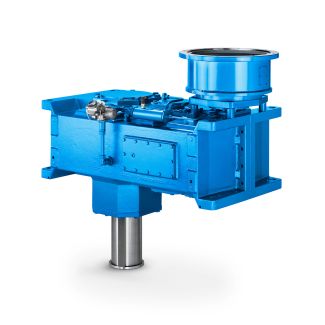

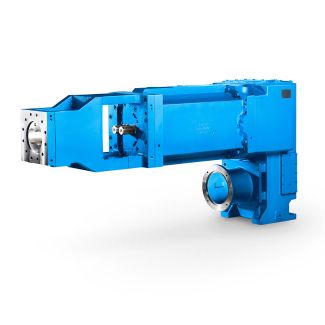

H4CH-18-C tal stipulations our services are becoming a deci Helical gear Reduction Box H4

In stock

SKU

H4CH-18-C

$83,035.71

Flender/Flender Gear Units/Helical gear Reduction Box H4

gs Service & Support:http://support.automation.siemens speed reducers/WW/view/en/1/1 Lubricants:http://support.automation.siemens speed reducers/WW/view/en/4/1 Michel Wendling is the Manager of the Client Support Department of Flender-Graffenstaden, in Illkirch-Graffenstaden,France. He has more than 3 years experience in the field of high-speed turbogears. His activities today includeinspection

Flender-Graffenstaden, in Illkirch-Graffenstaden,France. He has more than 3 years experience in the field of high-speed turbogears. His activities today includeinspection  on site, studding for revamping,as well as improvement of gearbox designby using return of experiences. Mr. Wendling has diploma (Electricity

on site, studding for revamping,as well as improvement of gearbox designby using return of experiences. Mr. Wendling has diploma (Electricity  and Mechanical Engineering) from the High National School of Nancy and received Dr-Ing. degree from the University of Grenoble, in

and Mechanical Engineering) from the High National School of Nancy and received Dr-Ing. degree from the University of Grenoble, in  France. Edwin Becker is the Manager of the Condition-Monitoring Department ofFlender Service GmbH, in Herne,Germany. Before joining the FlenderGroup in 1, he worked 1 years forASUG Getriebwerk, in Dessau, Germany, first in the Design and Research Department, and then in the After Sales andQuality Department. Dr. Becker received his Dr.rer.nat from the University of Halle/Saale, in Germany. ABSTRACT As result of cost reductions, there are fewer and fewer gear specialists in compressor and turbine companies, as well as in themaintenance groups of users. Therefore, these groups rely on thegear manufacturers expertise for gear maintenance. This paper is based on the authors field experience. It uses examples and case studies of investigation and troubleshooting.The use of vibration analysis for gearboxes having multiplesources of excitation is examined. The paper proposes differentsolutions to increase reliability and availability of gearboxesinstalled on turbo units. An important chapter deals with modernequipment for condition monitoring, which offers direct Internetlink between site and gearbox diagnostic specialists. INTRODUCTION Gearboxes, whether used for turbo units or for low-speed applications, are unique. Gearboxes are passive units, installedbetween drivers and driven machines, with excitations comingfrom two directio

France. Edwin Becker is the Manager of the Condition-Monitoring Department ofFlender Service GmbH, in Herne,Germany. Before joining the FlenderGroup in 1, he worked 1 years forASUG Getriebwerk, in Dessau, Germany, first in the Design and Research Department, and then in the After Sales andQuality Department. Dr. Becker received his Dr.rer.nat from the University of Halle/Saale, in Germany. ABSTRACT As result of cost reductions, there are fewer and fewer gear specialists in compressor and turbine companies, as well as in themaintenance groups of users. Therefore, these groups rely on thegear manufacturers expertise for gear maintenance. This paper is based on the authors field experience. It uses examples and case studies of investigation and troubleshooting.The use of vibration analysis for gearboxes having multiplesources of excitation is examined. The paper proposes differentsolutions to increase reliability and availability of gearboxesinstalled on turbo units. An important chapter deals with modernequipment for condition monitoring, which offers direct Internetlink between site and gearbox diagnostic specialists. INTRODUCTION Gearboxes, whether used for turbo units or for low-speed applications, are unique. Gearboxes are passive units, installedbetween drivers and driven machines, with excitations comingfrom two directio| Model Type | Helical gear Reduction Box H4 |

|---|---|

| Gear Type | Helical Gear |

| Weight (kg) | 3875.000000 |

| Ratio Range | 1 : 112…400 |

| Low Speed Output | Solid shaft without parallel key |

| Nominal Torque | 240000 Nm |

| Mounting Arrangements | Horizontal mounting position |

| Manufacturer | Flender de Colombia |

| Country of Manufacture | Israel |

| Data Sheet & Drawings | H4CH-18-C tal stipulations our services are becoming a deci Helical gear Reduction Box H4 |