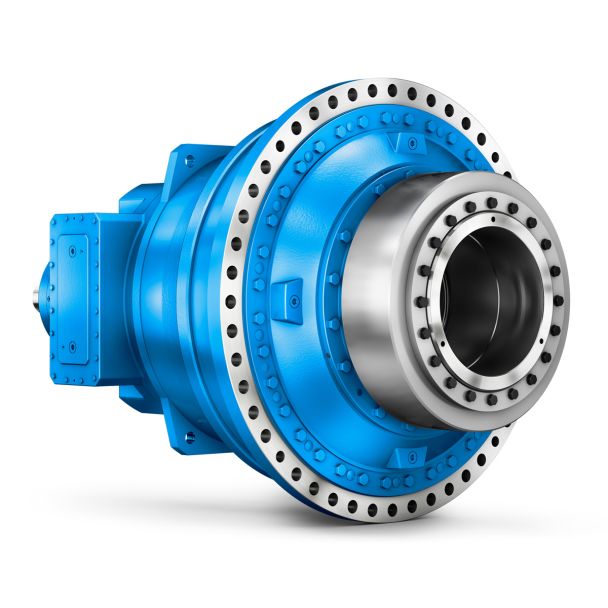

H4-KV-7-D I II n require power PI PII Pn and the res Helical speed reduction gearbox H4

In stock

SKU

H4-KV-7-D

$486,428.57

Flender/Flender Gear Units/Helical speed reduction gearbox H4

ional education track at an earlier age, may have interned with manufacturers, and are thus better prepared. The returns on training costs are not as certain for .. manufacturers, since the .. workforce is more likely to change employers than

training costs are not as certain for .. manufacturers, since the .. workforce is more likely to change employers than  is that of Europe and Japan. As result, small firms that provide entry-level training frequently lose workers to higher paying

is that of Europe and Japan. As result, small firms that provide entry-level training frequently lose workers to higher paying  large firms. 3 Raw Materials The raw materials and components used in producing gearing include variety of steel castings, forgings,

large firms. 3 Raw Materials The raw materials and components used in producing gearing include variety of steel castings, forgings,  and bar stock, as well as bronze castings and bearings. Other miscellaneous components include seals and lubrication oils. According to number of industry sources, material costs among the world' major producers of Japando the United States, Western Europe, and Japan do not vary significantly. 3Continued Verband Deutscher Maschinen- and Anlagenbau .. (VDMA), Associazione Italiana Costruttori Organi di Trasmissione Ingranaggi (ASSIOT), British Gear Association (BGA), and European industry officials in the United Kingdom, France, West Germany, and Italy, NovemberDecember 1. 3 USITC staff interview with major Japanese producer, December 1. 3 USITC staff interview with representative of the AGMA, Jan. 2, 1. 7-9 In Europe, most gear producers purchase steel and bronze locally in the United Kingdom, West Germany, Belgium, and the Netherlands, from the least expensive source available. In many instances, steel is purchased from distributors, usually subsidiaries of steel producers. West German and .. gear producers use different mixes of steel alloys in their products. Thus, it is difficult to compare steel prices. 3 Japanese gear industry sources also indicate that the steel they purchase is not directly comparable to that in the United States. Two major constraints on production are the availability of forgings and beanngs. 3 Forgings are typically used in input and output shafts and in blanks for some gears, such as pinions

and bar stock, as well as bronze castings and bearings. Other miscellaneous components include seals and lubrication oils. According to number of industry sources, material costs among the world' major producers of Japando the United States, Western Europe, and Japan do not vary significantly. 3Continued Verband Deutscher Maschinen- and Anlagenbau .. (VDMA), Associazione Italiana Costruttori Organi di Trasmissione Ingranaggi (ASSIOT), British Gear Association (BGA), and European industry officials in the United Kingdom, France, West Germany, and Italy, NovemberDecember 1. 3 USITC staff interview with major Japanese producer, December 1. 3 USITC staff interview with representative of the AGMA, Jan. 2, 1. 7-9 In Europe, most gear producers purchase steel and bronze locally in the United Kingdom, West Germany, Belgium, and the Netherlands, from the least expensive source available. In many instances, steel is purchased from distributors, usually subsidiaries of steel producers. West German and .. gear producers use different mixes of steel alloys in their products. Thus, it is difficult to compare steel prices. 3 Japanese gear industry sources also indicate that the steel they purchase is not directly comparable to that in the United States. Two major constraints on production are the availability of forgings and beanngs. 3 Forgings are typically used in input and output shafts and in blanks for some gears, such as pinions| Model Type | Helical speed reduction gearbox H4 |

|---|---|

| Gear Type | Helical Gear |

| Weight (kg) | 22700.000000 |

| Ratio Range | 1 : 100…355 |

| Low Speed Output | Hollow shaft with spline acc. to DIN 5480 |

| Nominal Torque | 21700 Nm |

| Mounting Arrangements | Vertical mounting position |

| Manufacturer | flanders electric peru s a c |

| Country of Manufacture | Germany |

| Data Sheet & Drawings | H4-KV-7-D I II n require power PI PII Pn and the res Helical speed reduction gearbox H4 |