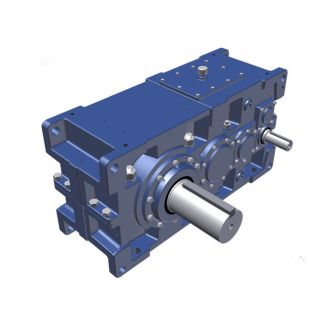

H4-HV-18B of dip lubrication Rotating components toothed Helical gear reducer H4

In stock

SKU

H4-HV-18B

$56,250.00

Flender/Flender Gear Units/Helical gear reducer H4

ich got into the steel by the ire-treatment can be desorbed during the conventional treatment, for example during resting time by diffusion. In the ,,single-step-process there is diffusion time of max. 1 minutes ayailable until the baking temperature of the

by diffusion. In the ,,single-step-process there is diffusion time of max. 1 minutes ayailable until the baking temperature of the  coating is reached. - Instead of phosphatization also chromatization can be used as an adhesion-promotor. The adhesion ofthefresh coatings is

coating is reached. - Instead of phosphatization also chromatization can be used as an adhesion-promotor. The adhesion ofthefresh coatings is  generally good. During theaging differentcharacteristicsof the different chromatizations have been detected. With raising chromium acid concen- tration and the increasing

generally good. During theaging differentcharacteristicsof the different chromatizations have been detected. With raising chromium acid concen- tration and the increasing  thickness of the intermediate layer the sizes of the ringformed adhesion structures are becoming bi ger, the adhesion mediating contact surfaces between coating and substrate are jecreasing (resulting ,from microscopic analysis: adhesion-patterns with yellow-chromatization FLENDER GRAFFENSTADEN 5-1 0 pm). The structuring of the coating surface increases accordingly. Therefore the best results have been realized with low content of chromium acid transparent chromatization. - No differences regardin the adhesion-strength of the compound system, if thedip-coating is charged with wet or 8ry phosphatizing layers. - Chromatizations as intermediate la ers have to be coated freshly (still wet) to obtain suffi- cient coating-adhesion. Aged dry cKromatizations show drophobe properties, therefore complete springkling in the coating bath is more difficd. - The adhesion-mediation of phosphatization layer is certainly better than blue or yellow chromatization, but the transparent chromatization is even better. 7 The motion of the bulkgoods could be realized with lowwaste-rate This has been reached - minimal bulk goods movement during coating, - adjusting good wetfilm-adhesion of the KTL-coating, - constructive steps which guarantee careful treatment of the bulk material in the whole - reloading device, - avoiding of stacked products after the coating, - using materials which cannot be wetted in the e

thickness of the intermediate layer the sizes of the ringformed adhesion structures are becoming bi ger, the adhesion mediating contact surfaces between coating and substrate are jecreasing (resulting ,from microscopic analysis: adhesion-patterns with yellow-chromatization FLENDER GRAFFENSTADEN 5-1 0 pm). The structuring of the coating surface increases accordingly. Therefore the best results have been realized with low content of chromium acid transparent chromatization. - No differences regardin the adhesion-strength of the compound system, if thedip-coating is charged with wet or 8ry phosphatizing layers. - Chromatizations as intermediate la ers have to be coated freshly (still wet) to obtain suffi- cient coating-adhesion. Aged dry cKromatizations show drophobe properties, therefore complete springkling in the coating bath is more difficd. - The adhesion-mediation of phosphatization layer is certainly better than blue or yellow chromatization, but the transparent chromatization is even better. 7 The motion of the bulkgoods could be realized with lowwaste-rate This has been reached - minimal bulk goods movement during coating, - adjusting good wetfilm-adhesion of the KTL-coating, - constructive steps which guarantee careful treatment of the bulk material in the whole - reloading device, - avoiding of stacked products after the coating, - using materials which cannot be wetted in the e| Model Type | Helical gear reducer H4 |

|---|---|

| Gear Type | Helical Gear |

| Weight (kg) | 2625.000000 |

| Ratio Range | 1 : 112…400 |

| Low Speed Output | Hollow shaft with keyway acc. to DIN 6885/1 |

| Nominal Torque | 240000 Nm |

| Mounting Arrangements | Vertical mounting position |

| Manufacturer | FLENDER GRAFFENSTADEN |

| Country of Manufacture | China |

| Data Sheet & Drawings | H4-HV-18B of dip lubrication Rotating components toothed Helical gear reducer H4 |