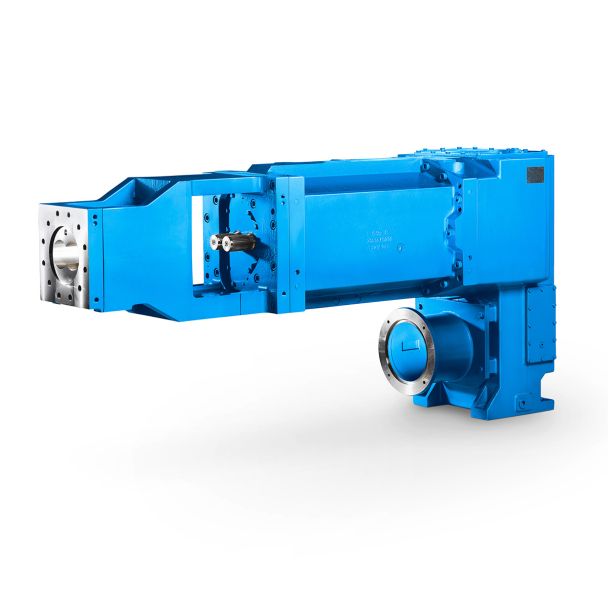

Helical speed reducer H4 Assumptions corresponding to operating conditions H4-FV-9-A

In stock

SKU

H4-FV-9-A

$6,857.14

Flender/Flender Gear Units/Helical speed reducer H4

l speed or acceleration. smooth slow sinusoidal mov ement by each turn of the mill is indicating eccentricity of the girth gear. Abrupt changes in axial position are indicating dangerous shock peaks caused by roundness or pitch problems in the

girth gear. Abrupt changes in axial position are indicating dangerous shock peaks caused by roundness or pitch problems in the  girth gear. Beside the traditional vibration analysis, the monitoring of the movement of the floating shaft brings great visibility about

girth gear. Beside the traditional vibration analysis, the monitoring of the movement of the floating shaft brings great visibility about  the condition of the drive train. This simple method is also known by the manufacturer of these type of gearboxes,

the condition of the drive train. This simple method is also known by the manufacturer of these type of gearboxes,  nevertheless usually the signals are not analyzed in way to get the full benefit out of them. The Floating Shaft Monitor analyzes the axial shaft movement and provides the amplitude, the speed or the acceleration as 4...2mA signals. Floating Shaft Monitor User Manual - January 1, 2 0 2/1 TomTom-Tools GmbH | Zelgli 2 | 8 Arni | Switzer land | Flender agent +4 5 6 9 2 2 SAFETY Ball Mills, where this system typically is used, ar huge rotating equipment with many pinch points which can cause serious injuries. Therefore, only specialized and trained personnel shall work close to these machines. For installatio , follow strictly the local safety rules given by the respective plant / factory / local authoriti es and discuss the application with the safety engineer in charge. The tools provided by TomTom-Tools GmbH have proven their functionality in various applications; nevertheless TomTom-Tools GmbH does ot take any responsibility for the application on site regarding safety or machine dam age. The plant is responsible for the safety, according to the local law, in way that obody can be hurt or injured. The application and safety instructions below are guide lines and not exhausted which include the experience from previous installations. They might need to be adapted to the local circumstances and safety requirements. Caution: Pinch Points: Do not put your hands nor any items close or into inch points. (.. tooth wheels, couplings

nevertheless usually the signals are not analyzed in way to get the full benefit out of them. The Floating Shaft Monitor analyzes the axial shaft movement and provides the amplitude, the speed or the acceleration as 4...2mA signals. Floating Shaft Monitor User Manual - January 1, 2 0 2/1 TomTom-Tools GmbH | Zelgli 2 | 8 Arni | Switzer land | Flender agent +4 5 6 9 2 2 SAFETY Ball Mills, where this system typically is used, ar huge rotating equipment with many pinch points which can cause serious injuries. Therefore, only specialized and trained personnel shall work close to these machines. For installatio , follow strictly the local safety rules given by the respective plant / factory / local authoriti es and discuss the application with the safety engineer in charge. The tools provided by TomTom-Tools GmbH have proven their functionality in various applications; nevertheless TomTom-Tools GmbH does ot take any responsibility for the application on site regarding safety or machine dam age. The plant is responsible for the safety, according to the local law, in way that obody can be hurt or injured. The application and safety instructions below are guide lines and not exhausted which include the experience from previous installations. They might need to be adapted to the local circumstances and safety requirements. Caution: Pinch Points: Do not put your hands nor any items close or into inch points. (.. tooth wheels, couplings| Model Type | Helical speed reducer H4 |

|---|---|

| Gear Type | Helical Gear |

| Weight (kg) | 320.000000 |

| Ratio Range | 1 : 100…355 |

| Low Speed Output | Flanged shaft |

| Nominal Torque | 35700 Nm |

| Mounting Arrangements | Vertical mounting position |

| Manufacturer | Flender Himmel RSA |

| Country of Manufacture | Germany |

| Data Sheet & Drawings | Helical speed reducer H4 Assumptions corresponding to operating conditions H4-FV-9-A |