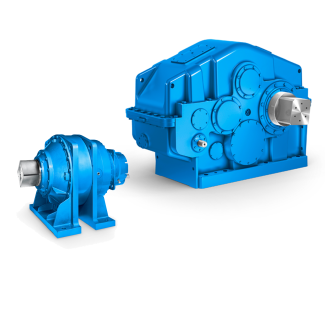

Helical gear units H4 fitted DTCRecalculation with variation of above a H4-FH-24-D

In stock

SKU

H4-FH-24-D

$210,000.00

Flender/Flender Gear Units/Helical gear units H4

kernel Fig. 2 longitudinal and cross section of kernel of wheat. (Courtesy of the North American Millers Assn.) 2 Sarkar could then be pearled and thus provide higher percentage of endosperm for suitable our production. Because pearling action through abrasion

could then be pearled and thus provide higher percentage of endosperm for suitable our production. Because pearling action through abrasion  or friction would still leave some bran in the crease area, different approach to bran removal must be applied. The

or friction would still leave some bran in the crease area, different approach to bran removal must be applied. The  crease thereforeposes technological challenge to the miller, making the separation of the bran more complex. Thegradual break and reduction system

crease thereforeposes technological challenge to the miller, making the separation of the bran more complex. Thegradual break and reduction system  was developed to meet this challenge. This processing system essentially involves the releasing of the endosperm from the wheatkernels on gradual basis and then the reduction of these endosperm particles into neour particles over number of stages. The milling process thus can be divided into the following three parts: 1. Breaking the wheat kernels and gradually releasing the endosperm in granular form 2. Grading of all the released granular endosperm, according to particle size, and its purication 3. Reduction of the puried granular endosperm particles into ne our particle size This sequence of the process has been graphically illustrated in Fig. 2. Even though grinding and sifting functions are repeated throughout the milling process, the specic objectives are not the same in all parts of the process. This has been explained earlier. Let us now look at the milling process, beginning with the very rst grinding step. 3.3.7.1 Breaking and Releasing the Endosperm Breaking and releasing the endosperm from wheat kernel begins when the cleaned and tempered wheat is initially ground using corrugated rolls that are carefully adjusted toprovide the appropriate gap between the grinding rolls to obtain satisfactory grinding re-sults. Satisfactory grinding results are dened by the following requirements: 1. Opening the wheat kernels sufciently to allow the release of some endosperm subject to the following constraints: Not to cut up the wheat too much. Not

was developed to meet this challenge. This processing system essentially involves the releasing of the endosperm from the wheatkernels on gradual basis and then the reduction of these endosperm particles into neour particles over number of stages. The milling process thus can be divided into the following three parts: 1. Breaking the wheat kernels and gradually releasing the endosperm in granular form 2. Grading of all the released granular endosperm, according to particle size, and its purication 3. Reduction of the puried granular endosperm particles into ne our particle size This sequence of the process has been graphically illustrated in Fig. 2. Even though grinding and sifting functions are repeated throughout the milling process, the specic objectives are not the same in all parts of the process. This has been explained earlier. Let us now look at the milling process, beginning with the very rst grinding step. 3.3.7.1 Breaking and Releasing the Endosperm Breaking and releasing the endosperm from wheat kernel begins when the cleaned and tempered wheat is initially ground using corrugated rolls that are carefully adjusted toprovide the appropriate gap between the grinding rolls to obtain satisfactory grinding re-sults. Satisfactory grinding results are dened by the following requirements: 1. Opening the wheat kernels sufciently to allow the release of some endosperm subject to the following constraints: Not to cut up the wheat too much. Not| Model Type | Helical gear units H4 |

|---|---|

| Gear Type | Helical Gear |

| Weight (kg) | 9800.000000 |

| Ratio Range | 1 : 112…400 |

| Low Speed Output | Flanged shaft |

| Nominal Torque | 725000 Nm |

| Mounting Arrangements | Horizontal mounting position |

| Manufacturer | Flender Ibérica S.A. |

| Country of Manufacture | Switzerland |

| Data Sheet & Drawings | Helical gear units H4 fitted DTCRecalculation with variation of above a H4-FH-24-D |