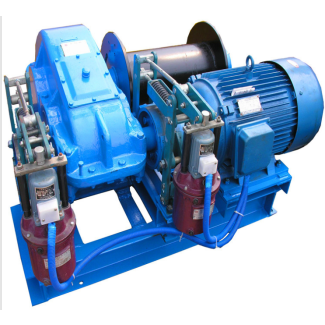

H4-DV-15-D Earth connection point Air relief point Yellow Oi Helical gearbox H4

In stock

SKU

H4-DV-15-D

$30,000.00

Flender/Flender Gear Units/Helical gearbox H4

indle motor calibration All repair work completed in-houseSERVOS Permanent magnet recharging Permanent magnet resolver repair Brushless motor repair Complete testing & documentation All repair work completed in-house SERVO AND SPINDLE MOTOR REPAIR 8 In-House Balancing Machines, Largest up to 2,0

& documentation All repair work completed in-house SERVO AND SPINDLE MOTOR REPAIR 8 In-House Balancing Machines, Largest up to 2,0  lbs Precision Machining PDMA Diagnostic Testing Line Boring Complete Repair of: Fans Pumps Blowers Gearboxes Centrifugal Blowers INDUSTRIAL EQUIPMENT REPAIR

lbs Precision Machining PDMA Diagnostic Testing Line Boring Complete Repair of: Fans Pumps Blowers Gearboxes Centrifugal Blowers INDUSTRIAL EQUIPMENT REPAIR  SERVICES Repairing an existing gearbox back to its original manufacturing standards can cost 4% less than the replacement unit and

SERVICES Repairing an existing gearbox back to its original manufacturing standards can cost 4% less than the replacement unit and  can even reduce turnaround time from 2 weeks to 4 weeks. Horner Industrial has years of experience servicing and repairing gearboxes from these brands: Flender, Hansen, Lufkin, Falk, Moog, SEW, Sumitomo and many more! GEARBOX REPAIR Welded, Built up with bronze thermal spray, then machined. PUMP REPAIR SERVICES Get the Horner Advantage with our ThermalLoct Process ThermalLoct Process ThermalLoct ProcessHorner Industrial Group is LOCTITE CERTIFIED APPLICATORSplit Case Centrifugal Multi-Stage Turbine Vacuum Slurry Submersible Restore Obsolete Components to Original Design Rebuild, Machine & Balance Impellers Apply Abrasion Resistant Coatings for Longer LifeTYPES OF PUMP REPAIR Repair and Rebuilds Complete Restoration of Obsolete Units Custom Parts Machining Knowledgeable mechanics with many years of experience We Service All Makes and Models Removal and Installation Services 2/7 Emergency Repair INDUSTRIAL BLOWER REPAIR EXPERTS IN HIGH VOLUME LOW PRESSURE FIELD SERVICES 2/7 EMERGENCY SERVICE2/7 EMERGENCY SERVICE Were always on call to service our customers needs whether its routine maintenance, unscheduled equipment emergencies, or assisting with preventative or predictive maintenance programs. Equipment Removal & Installation Infrared Thermography Laser Alignment On-site Machining On-site Fan & Blower Balancing PdMA Motor Condition MonitoringP

can even reduce turnaround time from 2 weeks to 4 weeks. Horner Industrial has years of experience servicing and repairing gearboxes from these brands: Flender, Hansen, Lufkin, Falk, Moog, SEW, Sumitomo and many more! GEARBOX REPAIR Welded, Built up with bronze thermal spray, then machined. PUMP REPAIR SERVICES Get the Horner Advantage with our ThermalLoct Process ThermalLoct Process ThermalLoct ProcessHorner Industrial Group is LOCTITE CERTIFIED APPLICATORSplit Case Centrifugal Multi-Stage Turbine Vacuum Slurry Submersible Restore Obsolete Components to Original Design Rebuild, Machine & Balance Impellers Apply Abrasion Resistant Coatings for Longer LifeTYPES OF PUMP REPAIR Repair and Rebuilds Complete Restoration of Obsolete Units Custom Parts Machining Knowledgeable mechanics with many years of experience We Service All Makes and Models Removal and Installation Services 2/7 Emergency Repair INDUSTRIAL BLOWER REPAIR EXPERTS IN HIGH VOLUME LOW PRESSURE FIELD SERVICES 2/7 EMERGENCY SERVICE2/7 EMERGENCY SERVICE Were always on call to service our customers needs whether its routine maintenance, unscheduled equipment emergencies, or assisting with preventative or predictive maintenance programs. Equipment Removal & Installation Infrared Thermography Laser Alignment On-site Machining On-site Fan & Blower Balancing PdMA Motor Condition MonitoringP| Model Type | Helical gearbox H4 |

|---|---|

| Gear Type | Helical Gear |

| Weight (kg) | 1400.000000 |

| Ratio Range | 1 : 100…355 |

| Low Speed Output | Hollow shaft with shrink disk |

| Nominal Torque | 153000 Nm |

| Mounting Arrangements | Vertical mounting position |

| Manufacturer | A. Friedr. Flender AG & Co. KG |

| Country of Manufacture | China |

| Data Sheet & Drawings | H4-DV-15-D Earth connection point Air relief point Yellow Oi Helical gearbox H4 |