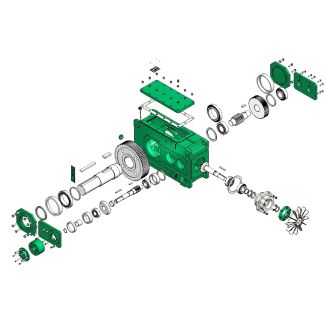

Helical speed reducer H3 flender zapex gear coupling catalogue H3VV-28-C

In stock

SKU

H3VV-28-C

$546,428.57

Flender/Flender Gear Units/Helical speed reducer H3

d ; (1 gear unit per item) Factory 4.1 6.1 End temperature ; Factory 4.1 6.1 Paint thickness (1 gear unit per item) Factory 4.1 6.1 Alignment log for IDS drive unit on swing base/base frame Factory Factory confirmation Function

unit per item) Factory 4.1 6.1 Alignment log for IDS drive unit on swing base/base frame Factory Factory confirmation Function  test run per direction of rotation (without load), check and confirmation of oil tightness, normal heat and noise development, and

test run per direction of rotation (without load), check and confirmation of oil tightness, normal heat and noise development, and  general visual acceptance)Factory Factory confirmation Total circumferential backlash for gear unit (on high speed shaft (HSS), low speed shaft (LSS)

general visual acceptance)Factory Factory confirmation Total circumferential backlash for gear unit (on high speed shaft (HSS), low speed shaft (LSS)  fixed)Factory Only practical for test station run "with at least partial load", load test or partial load test separately according to the table below. The test range encompasses: Load-free test run depending on type, size and type of lubrication, check for oil tightness, normal heat and noise development, and general visual acceptance, for meaningful measure- ment results order load/partial load test run at additional cost. Only practical with at least 4 hours of load-free test run (can be ordered separately). Only on the basis of the test sample of the furnace batch.The P4. tests are created by authorized employees at the factory. The P6. tests can be performed on request in the presence of the customer or by third party authorized by the customer when the order is placed. Please contact Flender in this regard. The contractually agreed upon test mea- sures remain the deliverables. Please request the load or partial load from Flender prior to placing the order to determine the additional costs. Flender GmbH 2NER GROUP CO.,LIMITED Germany sogears HB series gearbox 1/3 Flender MD 2.1 2Options for operation Devices and filters Pressure measuri ng instrument Overview Pressure measuring instru ment (pressure gauge) The pressure gauge can be used to carry out visual inspection of the function of forced lubrication. Any mounting position is possible. No warning or electronic evaluation can take place. Technical specifications Overview Pres

fixed)Factory Only practical for test station run "with at least partial load", load test or partial load test separately according to the table below. The test range encompasses: Load-free test run depending on type, size and type of lubrication, check for oil tightness, normal heat and noise development, and general visual acceptance, for meaningful measure- ment results order load/partial load test run at additional cost. Only practical with at least 4 hours of load-free test run (can be ordered separately). Only on the basis of the test sample of the furnace batch.The P4. tests are created by authorized employees at the factory. The P6. tests can be performed on request in the presence of the customer or by third party authorized by the customer when the order is placed. Please contact Flender in this regard. The contractually agreed upon test mea- sures remain the deliverables. Please request the load or partial load from Flender prior to placing the order to determine the additional costs. Flender GmbH 2NER GROUP CO.,LIMITED Germany sogears HB series gearbox 1/3 Flender MD 2.1 2Options for operation Devices and filters Pressure measuri ng instrument Overview Pressure measuring instru ment (pressure gauge) The pressure gauge can be used to carry out visual inspection of the function of forced lubrication. Any mounting position is possible. No warning or electronic evaluation can take place. Technical specifications Overview Pres| Model Type | Helical speed reducer H3 |

|---|---|

| Gear Type | Helical Gear |

| Weight (kg) | 25500.000000 |

| Ratio Range | 1 : 25…100 |

| Low Speed Output | Solid shaft with parallel key acc. to DIN 6885/1 with reinforced spigot |

| Nominal Torque | 1400000 Nm |

| Mounting Arrangements | Vertical mounting position |

| Manufacturer | A. Friedr. Flender GmbH |

| Country of Manufacture | Colombia |

| Data Sheet & Drawings | Helical speed reducer H3 flender zapex gear coupling catalogue H3VV-28-C |