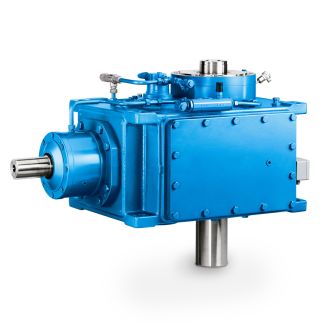

Flender/Flender Gear Units/Helical gearboxes H3

ECHNICAL SPECIFICATION MECON LIMITED REGD. OFF: RANCHI 8 OIL & GAS SBU, DELHI DOCUMENT NO. Page 8 of 6 TITLE MEC//0/2/0 REVISION : 0 PIPING FABRICATION AND ERECTION EDITION : 1 4.1 Mitre Bends and Fabricated Reducers The specific application

MEC//0/2/0 REVISION : 0 PIPING FABRICATION AND ERECTION EDITION : 1 4.1 Mitre Bends and Fabricated Reducers The specific application  of welded mitre bends and fabrication reducers shall be governed by the Piping Material Specifications. Generally all 9 deg. mitre

of welded mitre bends and fabrication reducers shall be governed by the Piping Material Specifications. Generally all 9 deg. mitre  shall be 4-piece 3-weld type and 4 deg. mitres shall be 3-piece 2-weld type as per MECON Standa rd unless

shall be 4-piece 3-weld type and 4 deg. mitres shall be 3-piece 2-weld type as per MECON Standa rd unless  otherwise specified. Reducers shall be fabricated as per directions of Engineer-in-Charge. The radiographic requirements shall be as per Material Specifications for process and utility systems and NDT Specification for steam piping under IBR, radiographic requirements of IBR shall be complied with. 4.1 Cutting and Trimming of Standard Fittings & Pipes Components like pipes, elbows, couplings, half-couplings etc. hall be cut / trimmed / edge prepared wherever required to meet fabrication and erection requirements, as per drawings and instructions of Engineer-in-Charge. Nipples as required shall be prepared from straight length piping. 4.1 Galvanised Piping Galvanised carbon steel piping shall be completely cold worked, so as not to damage galvanised surfaces. This piping involves only threaded joints and additional external threading on pipes may be required to be done as per requirement. 4.1 Jacketed Piping The Jacketing shall be done in accordance with MECON Specification or Licensors specification as suggested in material specification or special condition of contract. Pre-assembly of jacketed elements to the maximum extent possibl shall be accomplished at shop by Contractor. Position of jumpover and nozzles on the jac ket pipes, fittings etc. shall be marked according to pipe disposition and those shall be prefabricated to avoid damaging of inner pipe and obstruction of jacket space. However, valves, fl ow glasses, in line instruments or even fittings shall be supp

otherwise specified. Reducers shall be fabricated as per directions of Engineer-in-Charge. The radiographic requirements shall be as per Material Specifications for process and utility systems and NDT Specification for steam piping under IBR, radiographic requirements of IBR shall be complied with. 4.1 Cutting and Trimming of Standard Fittings & Pipes Components like pipes, elbows, couplings, half-couplings etc. hall be cut / trimmed / edge prepared wherever required to meet fabrication and erection requirements, as per drawings and instructions of Engineer-in-Charge. Nipples as required shall be prepared from straight length piping. 4.1 Galvanised Piping Galvanised carbon steel piping shall be completely cold worked, so as not to damage galvanised surfaces. This piping involves only threaded joints and additional external threading on pipes may be required to be done as per requirement. 4.1 Jacketed Piping The Jacketing shall be done in accordance with MECON Specification or Licensors specification as suggested in material specification or special condition of contract. Pre-assembly of jacketed elements to the maximum extent possibl shall be accomplished at shop by Contractor. Position of jumpover and nozzles on the jac ket pipes, fittings etc. shall be marked according to pipe disposition and those shall be prefabricated to avoid damaging of inner pipe and obstruction of jacket space. However, valves, fl ow glasses, in line instruments or even fittings shall be supp| Model Type | Helical gearboxes H3 |

|---|---|

| Gear Type | Helical Gear |

| Weight (kg) | 1400.000000 |

| Ratio Range | 1 : 25…90 |

| Low Speed Output | Hollow shaft with shrink disk |

| Nominal Torque | 61600 Nm |

| Mounting Arrangements | Vertical mounting position |

| Manufacturer | Flender Guss Gmbh & Co. Kg |

| Country of Manufacture | Egypt |

| Data Sheet & Drawings | H3DV-11-C flender service Helical gearboxes H3 |