Flender/Flender Gear Units/Helical gear Reduction Box H3

c relationship (source local spot size, max and min source strength, object to film distance, radiation angle with respect to weld and film). 1. Limit of film coverage 1. Film type and make 1. Exposure Time 1. Processing (time temperature

weld and film). 1. Limit of film coverage 1. Film type and make 1. Exposure Time 1. Processing (time temperature  for development stop bath or inse, fixation, washing, drying etc.) 1. Density 1. Sensitivity 1. Type of penetrameter RACTOR 1

for development stop bath or inse, fixation, washing, drying etc.) 1. Density 1. Sensitivity 1. Type of penetrameter RACTOR 1  of 1 STANDARD TECHNICAL SPECIFICATION MECON LIMITED REGD. OFF: RANCHI 8 OIL & GAS SBU, DELHI DOCUMENT NO. Page 4

of 1 STANDARD TECHNICAL SPECIFICATION MECON LIMITED REGD. OFF: RANCHI 8 OIL & GAS SBU, DELHI DOCUMENT NO. Page 4  of 6 TITLE MEC//0/2/0 REVISION : 0 PIPING FABRICATION AND ERECTION EDITION : 1 WELDING SPECIFICATION CHART EXHIBIT- Sheet 1 of 2 Class : Material Specification : Pipes : API 5L Gr. 6, API 5L Gr. API 5L Gr. 4 Fittings : 1, A2 Gr. WPB. MSS-SP-7, Gr. WPHY4, MSS- Flanges : 1, MSS-SP-4 Gr . F4, MSS-SP as Gr. WPH 6 Other : 4 Gr. F6C Base Metal of NCL : Welding Processes : Groove Joints : Butt Root Pass SMAW Filler Pass SMAW Root Pass SMAW Filler Pass SMAW Filler Joints/ Socket Joints : SMAW Welding Materials : Groove Joints : Butt Root Pass E6G/ E7G Filler Pass F7G/ E8G/ E8G Root Pass E7/ E7G/ E8G Filler Pass F7/ E7G/ E8 1G Filler Joints/ Socket Joints : E7/ E7/ E7G/ E8G Backing Page Consumable : Gases : Purging Sheilding Gas Composition : Purging Sheilding Preheating : 1 min for all welds, 1 qC Post heating Post weld heat treatment : Holding temp. : 5-6 Holding Time : 1 Hr. per inch thk Rate of heating : 2 /hr max . Min holding time : 1 . Method of cooling : Controlled Rate of cooling : 2 qC/h

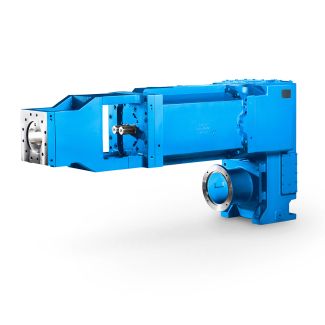

of 6 TITLE MEC//0/2/0 REVISION : 0 PIPING FABRICATION AND ERECTION EDITION : 1 WELDING SPECIFICATION CHART EXHIBIT- Sheet 1 of 2 Class : Material Specification : Pipes : API 5L Gr. 6, API 5L Gr. API 5L Gr. 4 Fittings : 1, A2 Gr. WPB. MSS-SP-7, Gr. WPHY4, MSS- Flanges : 1, MSS-SP-4 Gr . F4, MSS-SP as Gr. WPH 6 Other : 4 Gr. F6C Base Metal of NCL : Welding Processes : Groove Joints : Butt Root Pass SMAW Filler Pass SMAW Root Pass SMAW Filler Pass SMAW Filler Joints/ Socket Joints : SMAW Welding Materials : Groove Joints : Butt Root Pass E6G/ E7G Filler Pass F7G/ E8G/ E8G Root Pass E7/ E7G/ E8G Filler Pass F7/ E7G/ E8 1G Filler Joints/ Socket Joints : E7/ E7/ E7G/ E8G Backing Page Consumable : Gases : Purging Sheilding Gas Composition : Purging Sheilding Preheating : 1 min for all welds, 1 qC Post heating Post weld heat treatment : Holding temp. : 5-6 Holding Time : 1 Hr. per inch thk Rate of heating : 2 /hr max . Min holding time : 1 . Method of cooling : Controlled Rate of cooling : 2 qC/h| Model Type | Helical gear Reduction Box H3 |

|---|---|

| Gear Type | Helical Gear |

| Weight (kg) | 4560.000000 |

| Ratio Range | 1 : 22.4…90 |

| Low Speed Output | Solid shaft with parallel key acc. to DIN 6885/1 |

| Nominal Torque | 200000 Nm |

| Mounting Arrangements | Horizontal mounting position |

| Manufacturer | A. Fried. Flender AG |

| Country of Manufacture | China |

| Data Sheet & Drawings | H3-SH-17-A fledner Helical gear Reduction Box H3 |