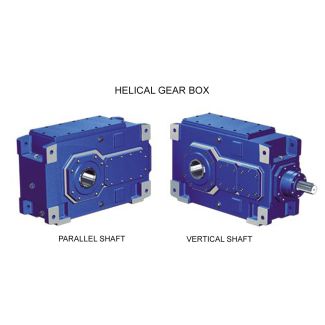

Flender/Flender Gear Units/Helical gear reducers H3

drying condi- tions are recommended as vegetable tissues are very heat sensitive. 4.2.5.1 Green Beans Green beans are dried on the trays of tunnel dryers or in belt dryers, either while still frozen or in thawed state. Two-step tunnel drying

the trays of tunnel dryers or in belt dryers, either while still frozen or in thawed state. Two-step tunnel drying  is recommended (: rst at 9 and then at 6 . nal moisture content of 5% (..) is typically target

is recommended (: rst at 9 and then at 6 . nal moisture content of 5% (..) is typically target  value. 4.2.5.2 Cabbage Cabbage typically is cored, trimmed, washed, and shredded by kraut cutters before blanch- ing and sulting. The

value. 4.2.5.2 Cabbage Cabbage typically is cored, trimmed, washed, and shredded by kraut cutters before blanch- ing and sulting. The  pretreated material is dried in two-stage tunnel dryer with an inletair temperature of about 8 in the rst (parallel airow) stage and 6 in the second (countercurrent airow) stage. nish drying step to lower moisture content of about 7% to 4% (..) is provided in stationary bin dryers, supplied with air at 5 . Strong com- pression of the dry product before packing was the standard procedure for cabbage packedin cans during World War II, but this procedure is not in use anymore. Practical information about other vegetable dehydration procedures can be found in specialized literature and recent publications (1,2,2,. 5 SPICES The quality of dry spices, culinary herbs, and spice blends is strongly affected by the drying method and drying conditions that are applied. The main attribute of spices is theimprovement of food avor and taste by some characteristic components, especially vola-tiles. These components are very heat-sensitive and should be preserved (to prevent evapo- ration or decomposition) to the maximal level during all processing steps. The drying process involves some thermal treatment, so the drying method and the conditions shouldbe very delicate and individually chosen for each type of spice or herb. Low-temperaturenatural or articial drying is the common practice. The measurement of moisture content in spices presents some unusual problems. Moisture is usually measured in food products by measuring the weight loss of sampleduring drying test at elevated (around 1 ) temperature or i

pretreated material is dried in two-stage tunnel dryer with an inletair temperature of about 8 in the rst (parallel airow) stage and 6 in the second (countercurrent airow) stage. nish drying step to lower moisture content of about 7% to 4% (..) is provided in stationary bin dryers, supplied with air at 5 . Strong com- pression of the dry product before packing was the standard procedure for cabbage packedin cans during World War II, but this procedure is not in use anymore. Practical information about other vegetable dehydration procedures can be found in specialized literature and recent publications (1,2,2,. 5 SPICES The quality of dry spices, culinary herbs, and spice blends is strongly affected by the drying method and drying conditions that are applied. The main attribute of spices is theimprovement of food avor and taste by some characteristic components, especially vola-tiles. These components are very heat-sensitive and should be preserved (to prevent evapo- ration or decomposition) to the maximal level during all processing steps. The drying process involves some thermal treatment, so the drying method and the conditions shouldbe very delicate and individually chosen for each type of spice or herb. Low-temperaturenatural or articial drying is the common practice. The measurement of moisture content in spices presents some unusual problems. Moisture is usually measured in food products by measuring the weight loss of sampleduring drying test at elevated (around 1 ) temperature or i| Model Type | Helical gear reducers H3 |

|---|---|

| Gear Type | Helical Gear |

| Weight (kg) | 2625.000000 |

| Ratio Range | 1 : 28…112 |

| Low Speed Output | Hollow shaft with keyway acc. to DIN 6885/1 |

| Nominal Torque | 113000 Nm |

| Mounting Arrangements | Horizontal mounting position |

| Manufacturer | A. Friedr. Flender GmbH |

| Country of Manufacture | Mongolia |

| Data Sheet & Drawings | flender coupling H3-HH14A Helical gear reducers H3 |