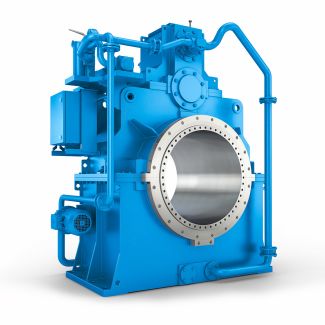

H3-FV-20B siemens flender gearbox Helical gear units H3

In stock

SKU

H3-FV-20B

$173,571.43

Flender/Flender Gear Units/Helical gear units H3

ess than penny-per-bushel (Chekerda, . Controlled Atmosphere Storage of Grain 2 The only drawback to using CO 2in concrete elevators is that extended use can cause signicant carbonation with gradual exposure of reinforcing steel, which may rust andweaken (Banks and

is that extended use can cause signicant carbonation with gradual exposure of reinforcing steel, which may rust andweaken (Banks and  McCabe, , although this problem was considered minor by theauthors. 1 RAILROAD HOPPER CARS Extensive efforts to make railroad hopper

McCabe, , although this problem was considered minor by theauthors. 1 RAILROAD HOPPER CARS Extensive efforts to make railroad hopper  cars airtight for fumigation of grain with CO were unsuccessful even in stationary car. The top berglass hatches and bottom

cars airtight for fumigation of grain with CO were unsuccessful even in stationary car. The top berglass hatches and bottom  hoppers require design modications to make the cars suitable for CA (Mann et al., 1c). 1 COMMERCIAL USE OF CA Australians were the original pioneers in the use of CA for grain treatment. Large percent- ages of farm bins are now constructed airtight (rolled steel), with pressure-relief valvesfor either standard phosphine or CO 2fumigation. At one time in the mid-1s ware- house holding 3,0 metric ton of wheat was regularly treated with CO 2piped from nearby industrial park (Kwinana, Western Australia). About 3 metric tons of CO 2were placed in the 3,0-metricton shed and recirculated; 5 extra tonnes were added perday. Insects were controlled in 1-days (Mills and White, 1; Ripp, . Currently, bins with CA capability are being installed in newly constructed grain terminal elevator run by Cargill Ltd. and Alberta Wheat Pool in Vancouver, British Colum-bia, Canada. The use of CA in grain storage can be practical and cost-effective if supplies of CO 2are readily available and essentially airtight structures are available. The most feasible structure present on farms or at primary elevators is welded steel hopper bin that hasbeen retrot with appropriate seals, pressure-relief valve, and recirculation pump. ACKNOWLEDGMENT We thank . Sims, Cereal Research Centre, AAFC, Winnipeg, Manitoba, for preparing the gures. REFERENCES Alagusundaram , Jayas DS, Muir WE, White NDG, Sinha RN (. Distribution of introduced carbon dioxide in farm granaries: an experi

hoppers require design modications to make the cars suitable for CA (Mann et al., 1c). 1 COMMERCIAL USE OF CA Australians were the original pioneers in the use of CA for grain treatment. Large percent- ages of farm bins are now constructed airtight (rolled steel), with pressure-relief valvesfor either standard phosphine or CO 2fumigation. At one time in the mid-1s ware- house holding 3,0 metric ton of wheat was regularly treated with CO 2piped from nearby industrial park (Kwinana, Western Australia). About 3 metric tons of CO 2were placed in the 3,0-metricton shed and recirculated; 5 extra tonnes were added perday. Insects were controlled in 1-days (Mills and White, 1; Ripp, . Currently, bins with CA capability are being installed in newly constructed grain terminal elevator run by Cargill Ltd. and Alberta Wheat Pool in Vancouver, British Colum-bia, Canada. The use of CA in grain storage can be practical and cost-effective if supplies of CO 2are readily available and essentially airtight structures are available. The most feasible structure present on farms or at primary elevators is welded steel hopper bin that hasbeen retrot with appropriate seals, pressure-relief valve, and recirculation pump. ACKNOWLEDGMENT We thank . Sims, Cereal Research Centre, AAFC, Winnipeg, Manitoba, for preparing the gures. REFERENCES Alagusundaram , Jayas DS, Muir WE, White NDG, Sinha RN (. Distribution of introduced carbon dioxide in farm granaries: an experi| Model Type | Helical gear units H3 |

|---|---|

| Gear Type | Helical Gear |

| Weight (kg) | 8100.000000 |

| Ratio Range | 1 : 25…100 |

| Low Speed Output | Flanged shaft |

| Nominal Torque | 345000 Nm |

| Mounting Arrangements | Vertical mounting position |

| Manufacturer | Siemens Flender |

| Country of Manufacture | Slovakia |

| Data Sheet & Drawings | H3-FV-20B siemens flender gearbox Helical gear units H3 |