Flender/Flender Gear Units/Helical speed reducer H3

ded for the respective application. Most industrial gearboxes from all manufacturers in the field, including Flender, are oversized by up to 5 pe rcent. With Flender One and AIQ, we have the right tools to continuously eliminate this oversizing together

to 5 pe rcent. With Flender One and AIQ, we have the right tools to continuously eliminate this oversizing together  with our customers. As result, we will realize massive savings in raw materials, energy consumption, delivery times and installation space.

with our customers. As result, we will realize massive savings in raw materials, energy consumption, delivery times and installation space.  Any wa ste is eliminated in terms of the environment and costs. On the way to the customized gearbox In

Any wa ste is eliminated in terms of the environment and costs. On the way to the customized gearbox In  the future, further expansions of the Flender One platform will make it possible to configure gearboxes tailored to the respective application and the associated requirements. Despite maximum individuality, customers will benefit from the advantages of series production: Process efficiency in production and thus fast delivery times and low costs. This is made possible by real milestone in transmission manufacturing: the complete digitization of the engineering process. It triggers the design exactly Flender International GmbH Press Release Page 3/5 according to customer requirements and translates it into fully automated manufacturing and delivery process. Flender CEO Andreas Evertz states , "Flender One represents significant shift in how we think about gearboxes. It is not just mechanical iteration of its predecessor FSG but an entirely new solution from the first customer inquiry to operation in the plant. Rouven Daniel adds, " lender One stands for being more individual, efficient, and smarter. With an easy -to-understand configuration process, automated manufacturing, and comprehensive 3 - data and documentation in the cloud, it saves our customers valuable time. In operation, lender One excels with improved power dissipation and AIQ optimization, making it the most efficient Flender gearbox solution we have ever introduced." Proven Successor Flender One succeeds the renowned standard industrial gearbox ran

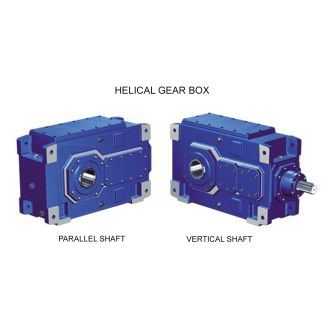

the future, further expansions of the Flender One platform will make it possible to configure gearboxes tailored to the respective application and the associated requirements. Despite maximum individuality, customers will benefit from the advantages of series production: Process efficiency in production and thus fast delivery times and low costs. This is made possible by real milestone in transmission manufacturing: the complete digitization of the engineering process. It triggers the design exactly Flender International GmbH Press Release Page 3/5 according to customer requirements and translates it into fully automated manufacturing and delivery process. Flender CEO Andreas Evertz states , "Flender One represents significant shift in how we think about gearboxes. It is not just mechanical iteration of its predecessor FSG but an entirely new solution from the first customer inquiry to operation in the plant. Rouven Daniel adds, " lender One stands for being more individual, efficient, and smarter. With an easy -to-understand configuration process, automated manufacturing, and comprehensive 3 - data and documentation in the cloud, it saves our customers valuable time. In operation, lender One excels with improved power dissipation and AIQ optimization, making it the most efficient Flender gearbox solution we have ever introduced." Proven Successor Flender One succeeds the renowned standard industrial gearbox ran| Model Type | Helical speed reducer H3 |

|---|---|

| Gear Type | Helical Gear |

| Weight (kg) | 1675.000000 |

| Ratio Range | 1 : 31.5…112 |

| Low Speed Output | Solid shaft without parallel key |

| Nominal Torque | 78000 Nm |

| Mounting Arrangements | Vertical mounting position |

| Manufacturer | A. Fried. Flender AG |

| Country of Manufacture | Uzbekistan |

| Data Sheet & Drawings | Helical speed reducer H3 flender rupex H3-CV12A |