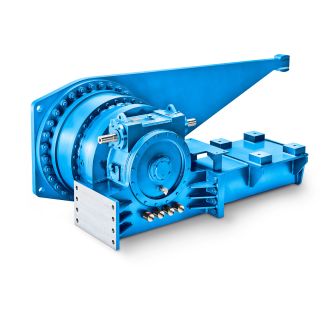

Helical gear Reduction Boxes H3 siemens flender gearbox H3-CV-24-D

In stock

SKU

H3-CV-24-D

$282,857.14

Flender/Flender Gear Units/Helical gear Reduction Boxes H3

differentfixation devicewhich wasto be univer- sal as regards its suitability for rocessing various yarns The calculation and design work for such fixation unit was carrie8out Its functional rinciple is that steam nozzle feeds the spacedyed yarn without tension from the

such fixation unit was carrie8out Its functional rinciple is that steam nozzle feeds the spacedyed yarn without tension from the  output rolronto specially structured conveyor belt, which is positively guided through the steaming/fixing and dryin zones. After leaving the dryer,

output rolronto specially structured conveyor belt, which is positively guided through the steaming/fixing and dryin zones. After leaving the dryer,  the yarn is drawn off the conveyor belt (on which it lies loose?) and spooled. In order first to test

the yarn is drawn off the conveyor belt (on which it lies loose?) and spooled. In order first to test  the exact, practical conditions when processing various yarns on such complete dyeing and fixation lant and to collect data, the first ste in the construction of the pilot plantwastoequip unit2 (iorcarpetyarns)withthefixationandPdryingdevice,justasin the pilot p1ant. steamer which belonged to the unit and which was constructed according to our dimensions and specifications was purchased. The experiments initially showed that this solu- tion was correct and should be expanded further. 4 3.2 Experiments by dyers with units 2 and 3 The dyeing experiments were pursued further by the dyers during the period covered by the report The ke aspectoftheexperiments on unit 2 with PA-yarnswastoobservethecolourchangeor the soih of the yarn in extended operation, based on the duration of dyeing of conventional yarn batcx Itwasfoundthat,aftersometime( prox 6 hours),theliquorconcentration increa- sed due to evaporation of the water (dye solent), which led to visible darkening of the colours During the course of the experiments, the dyers succeeded in keeping the liquor concentration constant and reducing the colour change throughout the entire processing time by adding controlled amount of water at the correct time During this time, the experiments carried out internally and by dyers failed to yield satisfactory results as regards colour uniformity from one processing location to another, due to the pre- viously determined defects in the

the exact, practical conditions when processing various yarns on such complete dyeing and fixation lant and to collect data, the first ste in the construction of the pilot plantwastoequip unit2 (iorcarpetyarns)withthefixationandPdryingdevice,justasin the pilot p1ant. steamer which belonged to the unit and which was constructed according to our dimensions and specifications was purchased. The experiments initially showed that this solu- tion was correct and should be expanded further. 4 3.2 Experiments by dyers with units 2 and 3 The dyeing experiments were pursued further by the dyers during the period covered by the report The ke aspectoftheexperiments on unit 2 with PA-yarnswastoobservethecolourchangeor the soih of the yarn in extended operation, based on the duration of dyeing of conventional yarn batcx Itwasfoundthat,aftersometime( prox 6 hours),theliquorconcentration increa- sed due to evaporation of the water (dye solent), which led to visible darkening of the colours During the course of the experiments, the dyers succeeded in keeping the liquor concentration constant and reducing the colour change throughout the entire processing time by adding controlled amount of water at the correct time During this time, the experiments carried out internally and by dyers failed to yield satisfactory results as regards colour uniformity from one processing location to another, due to the pre- viously determined defects in the| Model Type | Helical gear Reduction Boxes H3 |

|---|---|

| Gear Type | Helical Gear |

| Weight (kg) | 13200.000000 |

| Ratio Range | 1 : 25…100 |

| Low Speed Output | Solid shaft without parallel key |

| Nominal Torque | 725000 Nm |

| Mounting Arrangements | Vertical mounting position |

| Manufacturer | Flender..Ltd China(Tianjin) |

| Country of Manufacture | Ecuador |

| Data Sheet & Drawings | Helical gear Reduction Boxes H3 siemens flender gearbox H3-CV-24-D |