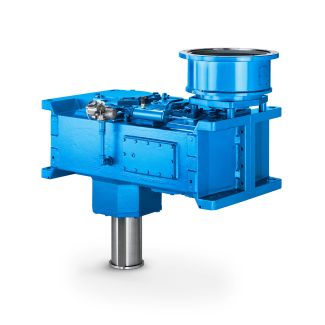

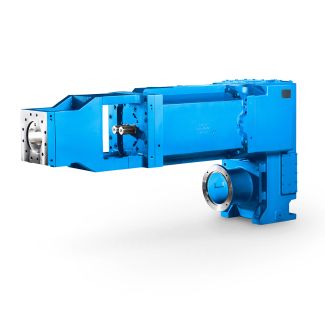

Flender/Flender Gear Units/Helical speed reducer H2

1 1 7 1 8 7 M3.8 1 1 6 1 1 9 1.9 2 1 9 1 1 1 1.9 2 1 1 2 1 1 M3.8 2 1 9 2 1 1 1.9 3 2 1 2 2

1.9 2 1 1 2 1 1 M3.8 2 1 9 2 1 1 1.9 3 2 1 2 2  2 1.9 4 2 1 3 2 2 M4.8 3 2 1 3 2 2 1.9 4 3 1 4

2 1.9 4 2 1 3 2 2 M4.8 3 2 1 3 2 2 1.9 4 3 1 4  4 3 1.9 5 3 2 5 4 4 M4.8 4 2 1 4 4 3 1.9 5 3 2

4 3 1.9 5 3 2 5 4 4 M4.8 4 2 1 4 4 3 1.9 5 3 2  6 5 5 1.9 7 4 2 7 6 6 M5.8 5 3 2 7 6 5 1.9 8 5 3 1 9 8 1.9 9 6 3 1 1 9 M6.8 7 4 2 1 9 8 1.9 1 6 4 1 1 1 1.9 1 7 4 1 1 1 M7x6.8 9 6 3 1 1 1 1.9 1 8 5 2 1 1 1.9 1 1 6 2 2 1 4 / 7BA 5 en 0/2Nominal thread diameterTightening torque for screw-connection classes from table 6Initial-tensioning force for screw-connection classes from table 6Strength class of the bolt mmMA NmFM min. M8x6.8 1 7 4 2 1 1 1.9 1 1 6 3 2 2 1.9 1 1 7 3 3 2 M9x6.8 1 9 6 3 2 2 1.9 2 1 8 4 3 3 1.9 2 1 1 5 4 3 M1x6.8 1 1 7 4 3 3 1.9 2 1 1 6 5 4 1.9 3 2 1 7 6 5 Note Damaged bolts must be replaced with new bolts of the same type and strength class. 4 / 7BA 5 en 0/2. Start-up Observe the instructions in section 3. "Safety instructions"! 7.1 Procedure before start-up 7.1.1 Removal of preservative agent from exterior The preserved shaft ends in the area of the couplings to be fitted must be depreserved, using suitable media (special solvent etc.). The depreservation also applies to bright surfaces of the gear unit, onto which components are to be fitted. CAUTION Risk of injury from chemical substances The solvent must not come into contact with the skin (.. the operator' hands). The safety notes on the data sheets for the solvent used must be observed. Immediately remove any spilled oil immediately using an oil binding agent. Observe manufacturer' instructions for handling lubricants and solvents.Wear suitable protective clothing. 7.1.2 Removal of preservative agent from interior NOTICE Property damage Damage to the gear unit due to absent or inadequate ventilation is possible.Replace the screw plug with the air filter or the wet air filter before start-up. The location of the oil draining points is marked by symbol in the dimensioned drawing in the gear unit documentation. Oil drain point: Place suitable containe

6 5 5 1.9 7 4 2 7 6 6 M5.8 5 3 2 7 6 5 1.9 8 5 3 1 9 8 1.9 9 6 3 1 1 9 M6.8 7 4 2 1 9 8 1.9 1 6 4 1 1 1 1.9 1 7 4 1 1 1 M7x6.8 9 6 3 1 1 1 1.9 1 8 5 2 1 1 1.9 1 1 6 2 2 1 4 / 7BA 5 en 0/2Nominal thread diameterTightening torque for screw-connection classes from table 6Initial-tensioning force for screw-connection classes from table 6Strength class of the bolt mmMA NmFM min. M8x6.8 1 7 4 2 1 1 1.9 1 1 6 3 2 2 1.9 1 1 7 3 3 2 M9x6.8 1 9 6 3 2 2 1.9 2 1 8 4 3 3 1.9 2 1 1 5 4 3 M1x6.8 1 1 7 4 3 3 1.9 2 1 1 6 5 4 1.9 3 2 1 7 6 5 Note Damaged bolts must be replaced with new bolts of the same type and strength class. 4 / 7BA 5 en 0/2. Start-up Observe the instructions in section 3. "Safety instructions"! 7.1 Procedure before start-up 7.1.1 Removal of preservative agent from exterior The preserved shaft ends in the area of the couplings to be fitted must be depreserved, using suitable media (special solvent etc.). The depreservation also applies to bright surfaces of the gear unit, onto which components are to be fitted. CAUTION Risk of injury from chemical substances The solvent must not come into contact with the skin (.. the operator' hands). The safety notes on the data sheets for the solvent used must be observed. Immediately remove any spilled oil immediately using an oil binding agent. Observe manufacturer' instructions for handling lubricants and solvents.Wear suitable protective clothing. 7.1.2 Removal of preservative agent from interior NOTICE Property damage Damage to the gear unit due to absent or inadequate ventilation is possible.Replace the screw plug with the air filter or the wet air filter before start-up. The location of the oil draining points is marked by symbol in the dimensioned drawing in the gear unit documentation. Oil drain point: Place suitable containe| Model Type | Helical speed reducer H2 |

|---|---|

| Gear Type | Helical Gear |

| Weight (kg) | 590.000000 |

| Ratio Range | 1 : 8…28 |

| Low Speed Output | Solid shaft with parallel key acc. to DIN 6885/1 with reinforced spigot |

| Nominal Torque | 25600 Nm |

| Mounting Arrangements | Horizontal mounting position |

| Manufacturer | A. Friedr. Flender GmbH |

| Country of Manufacture | Israel |

| Data Sheet & Drawings | H2-VH8A flender atb loher Helical speed reducer H2 |